Too detailed! what is API 5L Class B pipeline

What is Class A and Class B pipe?

What is API 5L Grade B pipe specification?

What is the difference between API 5L Grade B and ASTM A106 Grade B?

What is the pressure rating of API 5L Grade B pipe?

Purpose of API 5L Class B Pipe

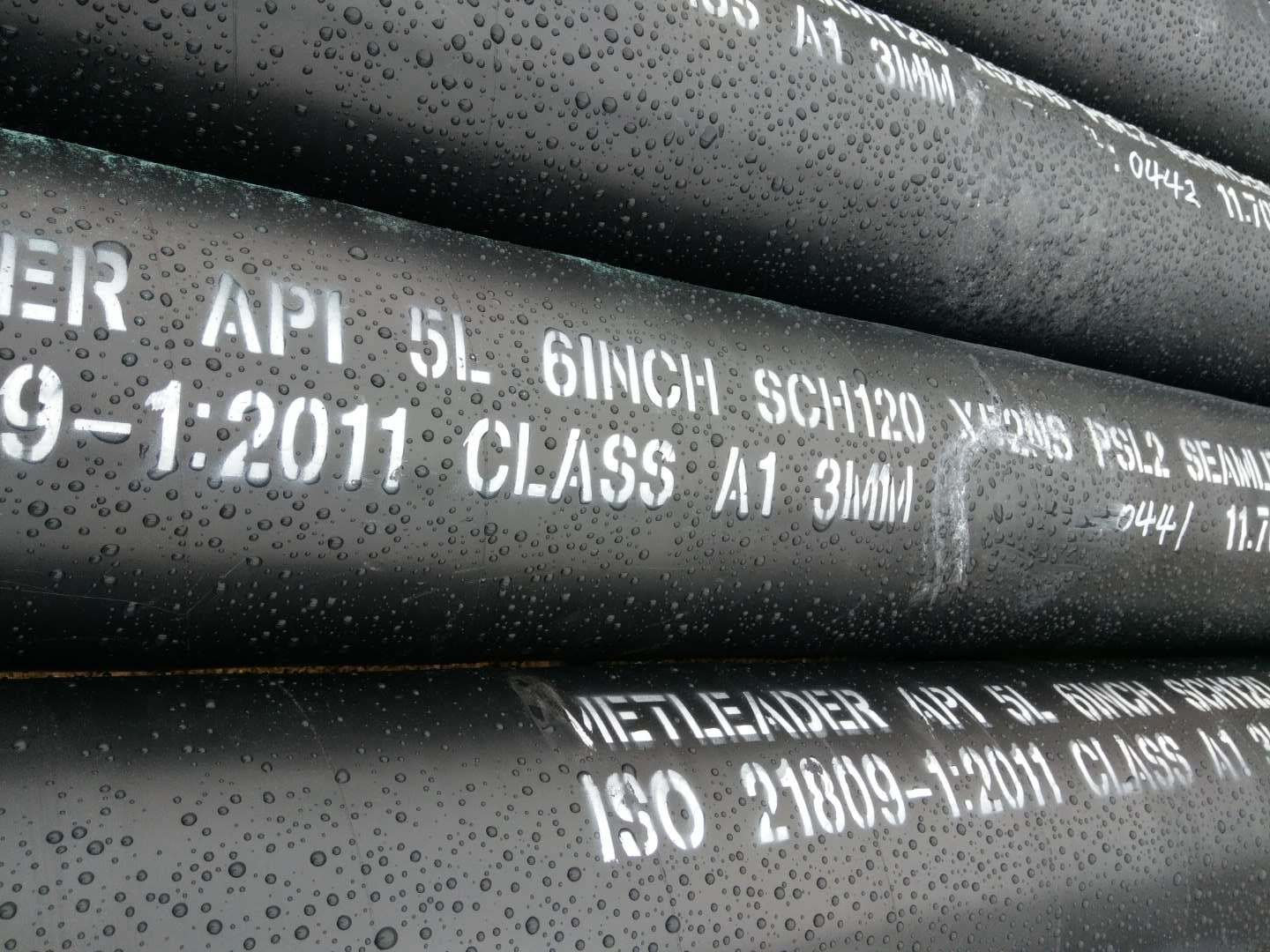

API 5L Grade B pipe is a type of steel pipe specified by the American Petroleum Institute (API) for use in conveying fluids such as oil, gas, and water within the oil and natural gas industries.

This grade of pipe adheres to the standards set forth in the API 5L specification. API 5L Grade B is characterized by its balanced chemical composition, including carbon, manganese, phosphorus, sulfur, and silicon, designed to meet specific mechanical and performance requirements.

These pipes can be manufactured through either seamless or welded processes, offering versatility for different applications.

With a minimum yield strength of 245 MPa and a minimum tensile strength of 415 MPa, API 5L Grade B pipes are known for their strength and durability.

Widely used in pipeline systems, these pipes play a crucial role in the transportation of energy resources, contributing to the reliability and efficiency of oil and gas infrastructure.

What is Class A and Class B pipe?

In the context of electrical conduit pipes, especially in the United States, Class A and Class B are used to distinguish between two types of rigid steel conduit (RSC) or intermediate metal conduit (IMC).

Class A: This designation is given to conduit pipes with a thicker wall, providing greater mechanical protection and strength. Class A conduit is typically used in more demanding or heavy-duty applications.

Class B: Conduit pipes with a thinner wall are classified as Class B. They are suitable for less demanding applications where the mechanical protection requirements are not as high.

What is API 5L Grade B pipe specification?

| Characteristic | Specification |

|---|---|

| Grade | API 5L Grade B |

| Chemical Composition | Carbon (C): ≤ 0.30% |

| Manganese (Mn): ≤ 1.20% | |

| Phosphorus (P): ≤ 0.025% | |

| Sulfur (S): ≤ 0.025% | |

| Silicon (Si): ≤ 0.45% | |

| Mechanical Properties | Yield Strength: ≥ 245 MPa (35,500 psi) |

| Tensile Strength: ≥ 415 MPa (60,200 psi) | |

| Minimum Elongation: 23% | |

| Usage | Conveying oil, gas, and water in pipeline systems |

| Manufacturing Methods | Seamless and Welded |

This table provides a basic overview of the API 5L Grade B pipe specification.

What is the difference between API 5L Grade B and ASTM A106 Grade B?

| Characteristic | API 5L Grade B | ASTM A106 Grade B |

|---|---|---|

| Purpose/Application | Conveying oil, gas, and water in pipelines | High-temperature service, seamless carbon steel pipes for high-pressure and high-temperature applications |

| Specification Reference | API 5L | ASTM A106 |

| Manufacturing Process | Seamless and welded | Seamless |

| Chemical Composition | Carbon (C): ≤ 0.30% | Carbon (C): ≤ 0.30% |

| Manganese (Mn): ≤ 1.20% | Manganese (Mn): 0.29-1.06% | |

| Phosphorus (P): ≤ 0.025% | Phosphorus (P): ≤ 0.05% | |

| Sulfur (S): ≤ 0.025% | Sulfur (S): ≤ 0.058% | |

| Silicon (Si): ≤ 0.45% | Silicon (Si): ≥ 0.10% | |

| Mechanical Properties | Yield Strength: ≥ 245 MPa (35,500 psi) | Yield Strength: ≥ 240 MPa (35,000 psi) |

| Tensile Strength: ≥ 415 MPa (60,200 psi) | Tensile Strength: ≥ 415 MPa (60,200 psi) | |

| Minimum Elongation: 23% | Minimum Elongation: 30% | |

| Usage | Commonly used in pipeline systems | High-temperature and high-pressure applications such as in refineries and power plants |

| Impact Testing Requirements | Required | Not specifically required |

This table provides a concise comparison of API 5L Grade B and ASTM A106 Grade B based on various characteristics.

What is the pressure rating of API 5L Grade B pipe?

API 5L Grade B pipe does not have a specific pressure rating like some other pipe specifications. Instead, the pressure rating depends on various factors including the size, wall thickness, and manufacturing method (seamless or welded).

The pressure rating for a particular API 5L Grade B pipe is typically determined by the applicable design code or standard that governs the specific application.

API 5L pipes are commonly used for conveying fluids such as oil, gas, and water in various industries.

When determining the pressure rating for a specific pipeline, it is important to refer to the relevant design code or standard that outlines the criteria for calculating the pressure containment capabilities of the pipe.

For example, if the pipeline is designed according to the ASME B31.4 code for oil and gas transmission pipelines or ASME B31.8 for gas transmission and distribution piping systems, the pressure rating will be determined based on factors such as wall thickness, diameter, material properties, and safety margins specified in those codes.

Always consult the applicable design code, project specifications, or industry standards to determine the pressure rating for a specific API 5L Grade B pipe in a given application.

Purpose of API 5L Class B Pipe

The primary purpose of API 5L Class B pipes is to serve as a reliable conduit for the transportation of oil and gas within pipeline systems.

These pipes are suitable for a range of applications where moderate strength and pressure requirements are essential.

Class B pipes are well-suited for use in midstream and downstream sectors of the oil and gas industry, contributing to the efficient and safe movement of hydrocarbons from production facilities to processing plants and distribution points.

API 5L Class B pipes are manufactured through both seamless and welded processes, offering flexibility in application.

Their affordability and ease of fabrication make them a practical choice for various infrastructure projects.

Overall, the purpose of API 5L Class B pipes is to provide a cost-effective and dependable solution for the transportation of fluids in industries that require reliable and durable piping systems.