What is CF flange (Conflat Flang)

The English name of CF flange is Conflat Flang.

It is a flange connection used in ultra-high vacuum and is a metal static seal that can withstand high temperature baking.

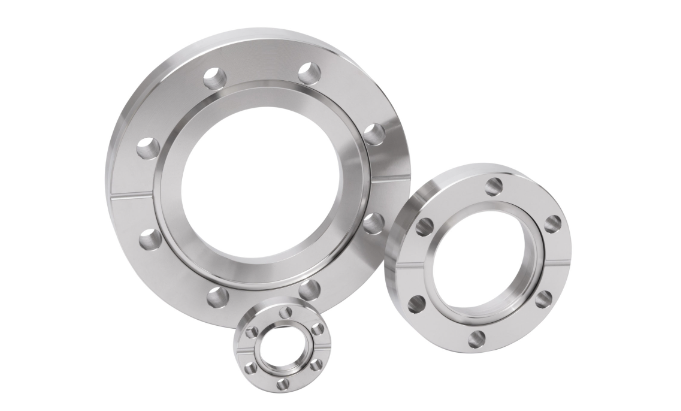

Nominal diameter sizes include: DN16, 40, 63, 100, 160, 200, 250.

The applicable vacuum degree is up to 10^-12 mbar. Flange sealing materials are usually Viton, PTFE, oxygen-free copper, etc.

Flanges are usually 304, 316 stainless steel, etc.

Table of models and sizes of commonly used CF flanges

The inside of the CF flange has a sharp raised edge, which is deformed by squeezing the oxygen-free copper gasket (or other soft metal) to achieve the purpose of sealing the vacuum.

It is an all-metal material seal. method, which is widely used in ultra-high vacuum systems.

CF flange is also commonly referred to as ICF flange.

The number after CF is the standard inner diameter of the conduit, and the number after ICF is the outer diameter of the flange.

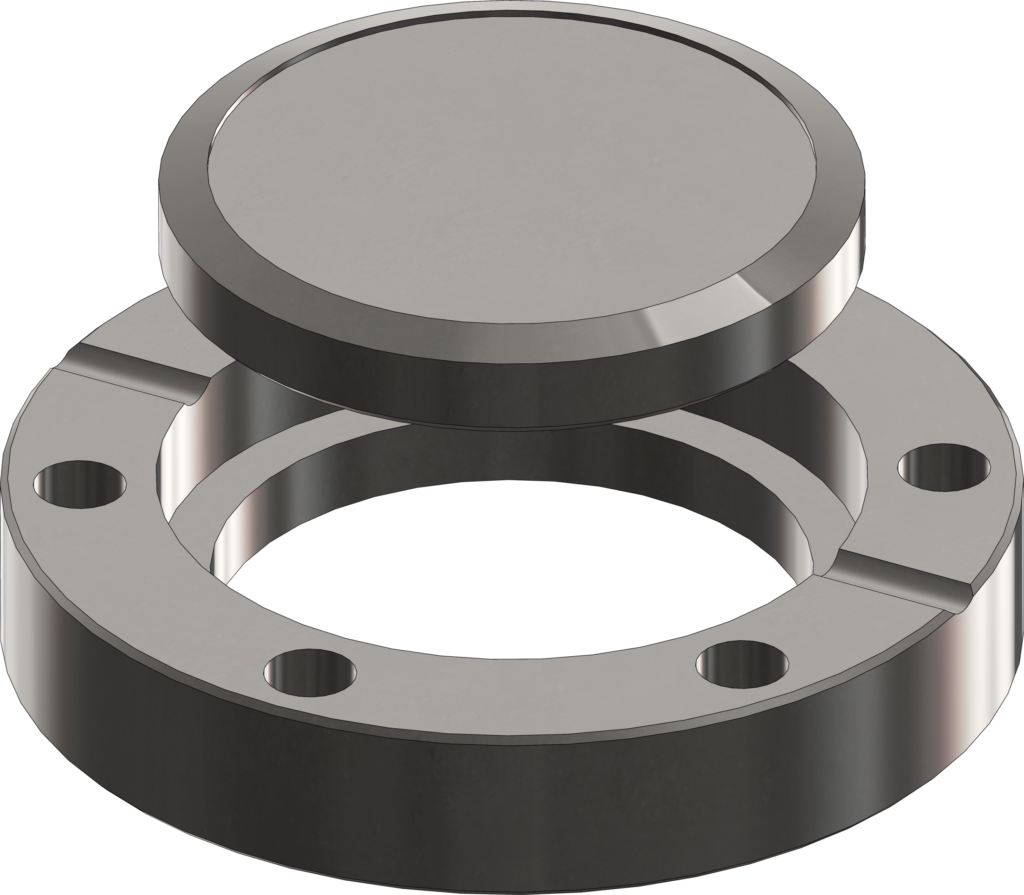

CF flanges are divided into two types: fixed type and loose sleeve type.

The fixed flange is an integrated structure. The loose-type flange consists of a knife edge part extruded from a copper gasket and a fixed part secured by bolts.

The flange can have through holes or threaded holes.

Flanges with through holes must be fixed with bolts and nuts; flanges with threaded holes can be fixed directly with bolts.

The material of the flange is mainly SUS304 (or SUS304L), because SUS304 releases less gas and is easier to process and weld.

The characteristic of CF flange is that it is gender-neutral and is made entirely of metal including the oxygen-free copper gasket, so it can withstand high temperature (above 250°C) baking.

The disadvantage is that the price is high and the oxygen-free copper gasket cannot be reused many times.

Installation of CF flange

The installation requirements of CF flange are higher.

Because the oxygen-free copper gasket will deform when squeezed, it is very important to tighten the bolts with equal force.

If the bolt force is uneven, the flange at the diagonal position will rise, causing air leakage.

The torque for tightening the bolts is approximately as follows: M4 bolts 20kgf·cm, M6 bolts 70kgf·cm, M8 bolts 100kgf·cm.

Precautions for using CF flange

There are several points to pay attention to when using CF flange: the bolts must be coated with MoS2 to prevent the bolts and nuts from interlocking and getting stuck; the outer periphery of the flange must be aligned; the flange surface must be kept at a distance to leave room for continued tightening of the bolts after baking.

In the CF flange, the knife edge must be cut into the metal sealing ring to achieve vacuum sealing.

With long-term use, the knife edge will gradually become dull. In addition, the knife edge is easily injured after being hit by a hard object.

One of the remedies at this time is to use IPD metal sealing rings.

The IPD metal sealing ring does not rely on the knife edge of the flange, but relies on the bevel on the outer periphery of the knife edge for sealing.