when fabricating a 90 degree bend, the distance to the bending mark is equal to?

when fabricating a 90 degree bend, the distance to the bending mark is equal to?

90 degree bend parts are a kind of parts with more practical applications. After bending 90°, the outer diameter of turning is processed. It is a difficult-to-machine part. Because it is 90° right angle, it is difficult to clamp, difficult to find and processing time. long. The general processing method adopts the four-claw correction of the lathe. The clamping time and the correction time are longer in this method. After the processing, the verticality is difficult to guarantee. After processing one piece, it needs to be re-clamped and corrected, which is not suitable for mass production. Time-consuming and labor-intensive.

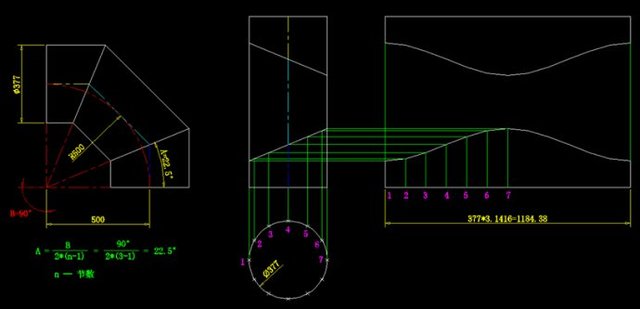

Taking the diameter of the bending center D=2.5d as an example

Poor bending measurement when bent at 90 degrees

[The method of outsourcing labeling, while labeling L (rebar length) and L1 (hook length)]

Outsourcing size: 2 (D / 2+d) = 2 (2.5d / 2dd) = 4.5d

Center line size: (D + d) π / 4 = (2.5d + d) π / 4 = 2.75d

Measurement difference: 4.5d-2.75d=1.75d

90 degree elbow manual stakeout

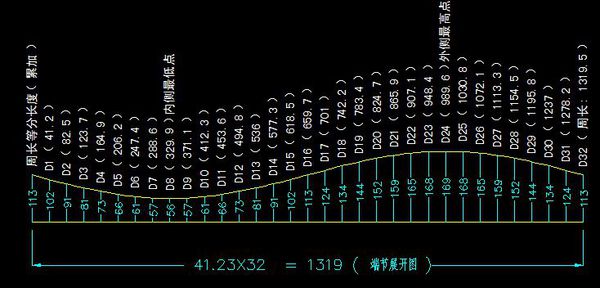

1, 90 degree elbow can be made into 4 sections of shrimp waist, can also be made into 5 sections, the reason is the same when manually staked out, now has 3 sections as an example, let’s talk about manual stakeout.

2. Draw the main view (as shown below).

3. The waist elbow joints can be twisted and aligned to form a straight tube (as shown below). Since the first section and the last section are half of the middle section, it is only necessary to expand the first section.

4. Divide the tube into 12 equal parts and lead the bisector to the cutting line.

5. From point 1, divide the aliquot into 12 equal parts and draw 12 vertical lines upwards. The height is measured from the first point of the left section and then intercepted on the corresponding vertical line. Smooth the various points obtained by the connection and complete the expanded view.