How to choose the right elbow: 90 degree elbow

Contents

- What is a 90 degree elbow

- 90 degree elbow production requirements

- Elbow selection guide

- Elbow precautions

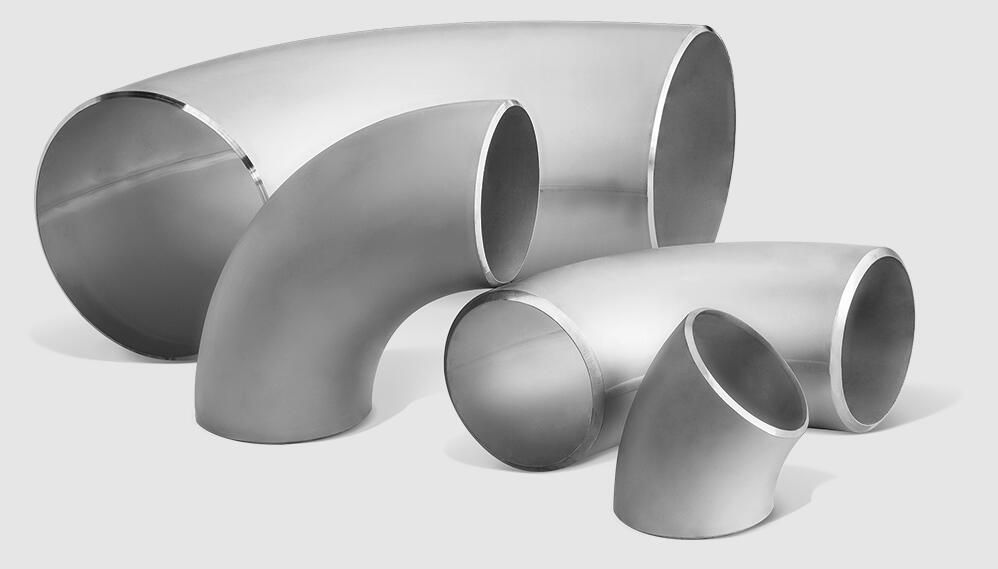

Elbow is a common component in the pipeline system, used to change the direction of the pipeline. It changes the direction by bending at different angles and is widely used in petrochemical, chemical, pharmaceutical, food, papermaking and other industries.

What is a 90 degree elbow

90-degree elbows are the most commonly used products among elbow accessories. As pipe accessories that need to be connected, right-angle pipes need to be connected in some fields of use.

Only 90-degree elbows can be used to connect normally. Therefore, 90° elbows represent elbow types at different angles. Common angle elbows include 45-degree and 180-degree straight angles.

In the engineering field, elbow products with different angles are also specially launched.

The materials used in the products cover a variety of materials, not only metal materials, but also plastic materials and alloy textures are used in product design.

90 degree elbow production requirements

The connection of the elbow parts is mostly completed by welding process.

In order to ensure high quality, the end of the elbow is made into a bevel, a certain slope is reserved, and the elbow has an edge, which needs to be strictly controlled.

The slope and edge size have a certain numerical area size. The surface manufacturing of the elbow is not much different from the manufacturing of the pipe.

The components contained in the elbow need to be processed again on the surface, and the oxidized inner and outer layers of the elbow are evenly coated with anti-rust paint through the spraying process.

This process is very important to facilitate the transportation of products, export to foreign markets, and reduce the wear of elbow products.

Elbow selection guide

Choosing a suitable elbow requires considering the following aspects:

Elbow types

Choose the appropriate elbow type based on the purpose and environment of the pipeline. For example, pipelines with high pressure and flow require high-strength, durable materials and specially designed elbows.

Elbow material and wall thickness

When choosing the appropriate elbow material and wall thickness, factors such as the chemical properties, temperature and pressure of the pipeline medium need to be considered.

Elbow bending radius

The bending radius of the elbow directly affects the flow performance of the pipeline. Choosing a suitable bending radius can reduce the pressure loss of the pipeline.

Elbow connection method

Select the appropriate elbow according to the pipe connection method, such as welding, threaded connection, etc.

Elbow precautions

When installing and using elbows, pay attention to the following matters:

- The connection thread of the elbow should meet the requirements and there should be no leakage.

- The pipe where the elbow is located should be firmly fixed to avoid the elbow from bearing additional load.

- Avoid the elbow with too large angle or too small radius, which will affect the normal operation of the pipeline.

- Check the status of the elbow regularly and replace the worn or aged elbow in time.

- Avoid excessive bending of the elbow, which will affect the circulation and transportation of the medium.

summary

Elbows are important components in the pipeline system, and the appropriate models and specifications need to be selected according to specific needs.

Through the understanding and application of the elbow parameter table, we can better select suitable elbows, and pay attention to the installation and use of elbows to ensure the normal operation of the pipeline.