Detailed explanation of reducer knowledge: Purchasing guide for the world’s top 500 companies

Table of contents

- Preface

- What is a reducer

- Classification of reducers

- Applications of reducers

- What does “bt” in reducers stand for

- Standards for reducers

- Specifications of reducers

- Concentric reducers vs eccentric reducers

- Reducers vs reducing nipples

- FAQ

- Summary

Preface

In the process of cooperation between Metleader and many Fortune 500 companies, we found that customers have very professional knowledge whether they are purchasing reducers or flange elbows.

Therefore, we have compiled an article about reducers today. The article contains the basic concepts of reducers and lists the differences between reducers and other similar pipe fittings.

These will help companies to better purchase pipe fittings and hope to help companies choose better suppliers.

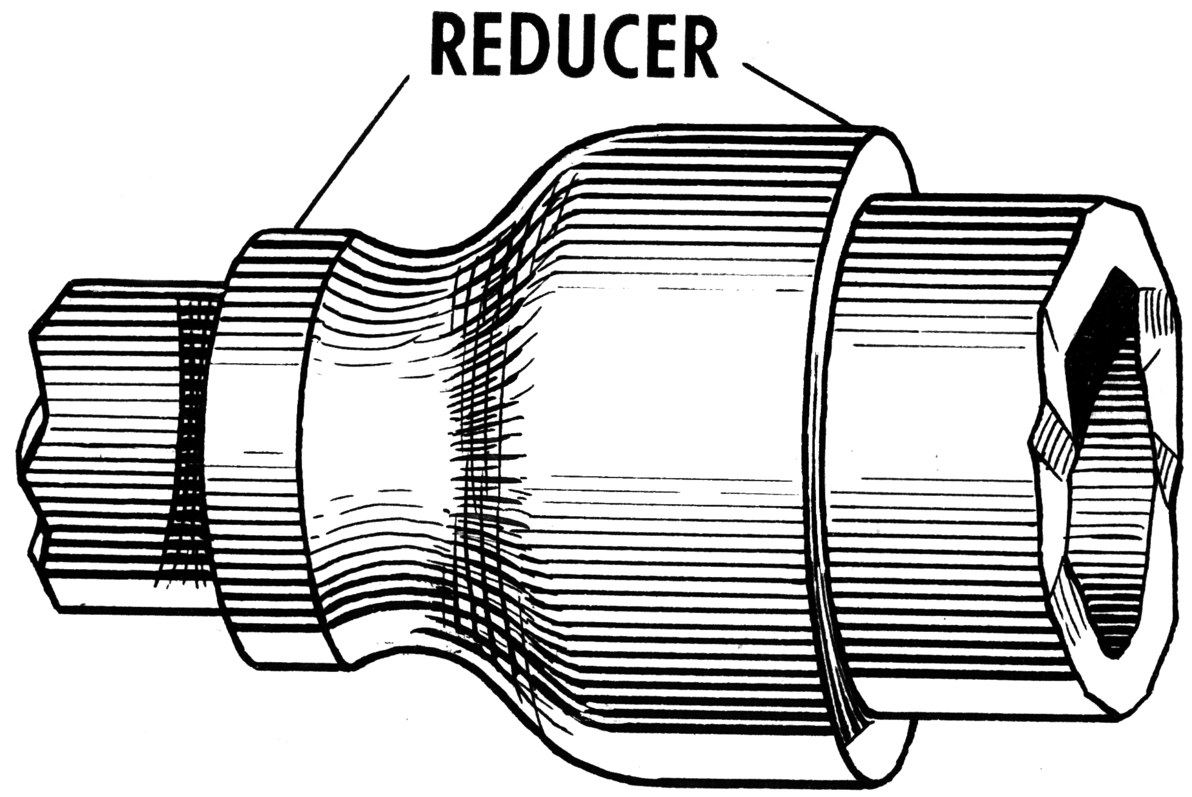

What is a reducer

A reducer is a common component in a piping system.

It is made up of two pipes of different diameters. It is generally used to connect two pipes of different diameters to achieve the purpose of connecting pipe diameter changes.

Classification of reducers

Reducers are divided into two categories: concentric reducers and eccentric reducers. Here we introduce these two types of pipe fittings:

What is a concentric reducer

A concentric reducer is a pipe connection device consisting of two or more coaxial metal pipes with different diameters.

What is an eccentric reducer

An eccentric reducer is a pipe connector with two ends of different diameters and the center lines are not in the same position.

It is usually used to connect two pipes of different diameters so that the fluid can be smoothly transmitted in the pipeline system.

Compared with a concentric reducer, the main difference of an eccentric reducer is that the center lines of its two ends do not coincide.

Applications of reducers

- In the power, chemical, metallurgical, shipbuilding and other industries, some industrial pipeline systems need to transport fluids or gases.

- When assembling pipelines for oil wells or water wells, reducers are needed to gradually transition to adapt to different terrains and pipeline requirements.

- Reducers are needed in medical equipment and cosmetic equipment.

What does “bt” in reducers stand for

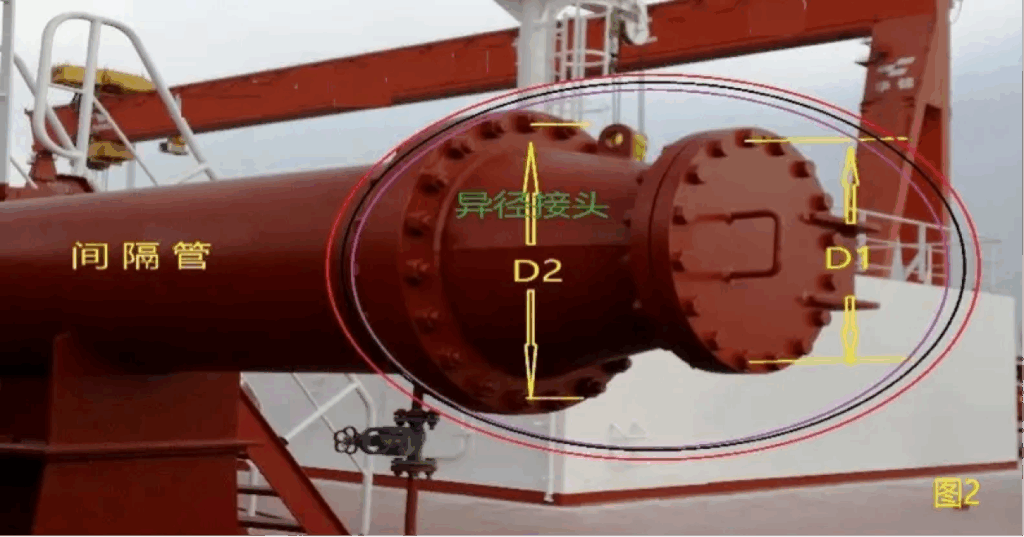

“bt” stands for the “big end diameter” of the reducer, that is, the diameter of the larger end of the reducer. This parameter directly affects the connection capacity and application range of the reducer.

Therefore, it is very important to clarify the value of “bt” when selecting and purchasing reducers.

For example, a common reducer specification may be “DN100x80”, which means that the small end diameter of the reducer is DN80, and the large end diameter (ie “bt”) is DN100.

Standards for reducers

Reducers follow a series of strict standards, such as ANSI B16.9/16.28, ASME, ASTM, API 5L, etc., and are also subject to specifications such as JIS P2311/2312, DIN2605/2615/2616 and ASME B36.10M-1996GB/T 12459a.

In terms of materials, reducers are usually made of materials such as ASTM A234 WPB, carbon steel, stainless steel or low alloy.

Its models range from 1/2″ to 72″, meeting the needs of different pipe connections.

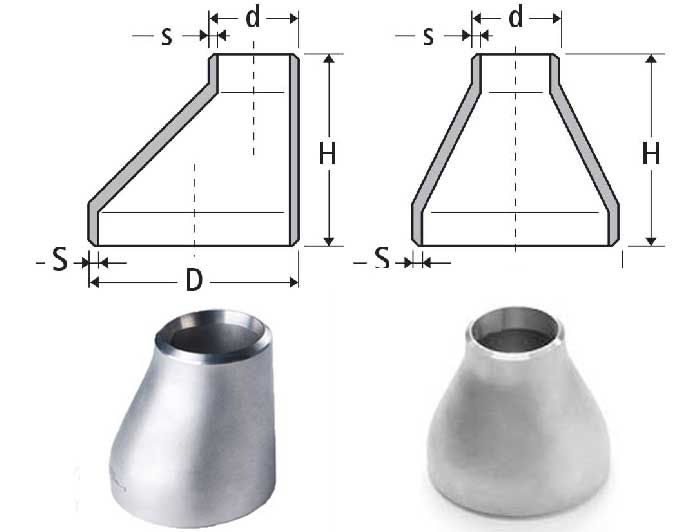

Specifications of reducers

| Reducer Size (DN) | D1 (mm) | D2 (mm) | L (mm) |

| 25×20 | 25 | 20 | 75 |

| 32×25 | 32 | 25 | 85 |

| 40×32 | 40 | 32 | 85 |

| 50×32 | 50 | 32 | 100 |

| 50×40 | 50 | 40 | 100 |

| 65×50 | 65 | 50 | 120 |

| 80×50 | 80 | 50 | 140 |

| 80×65 | 80 | 65 | 140 |

| 100×80 | 100 | 80 | 170 |

| 100×65 | 100 | 65 | 170 |

| 125×100 | 125 | 100 | 200 |

| 125×80 | 125 | 80 | 200 |

| 150×100 | 150 | 100 | 225 |

| 150×125 | 150 | 125 | 225 |

| 200×150 | 200 | 150 | 280 |

Concentric reducers vS eccentric reducers

Here’s comparison between concentric and eccentric reducers:

| Feature | Concentric Reducer | Eccentric Reducer |

| Shape | Symmetrical cone | One slanted side (“stair-step” look) |

| Center Line | Same for both ends | Off-center (not aligned) |

| Flow Direction | Smooth vertical flow | Turbulent at offset section |

| Liquid Drainage | Traps air pockets | Prevents air pockets |

| Installation | Always vertical position | Offset position matters: • TOP: Liquids • BOTTOM: Gases |

| Common Uses | • Vertical pipe runs • Pump inlets • Tank outlets | • Pipe racks • Drain lines • Pump suction |

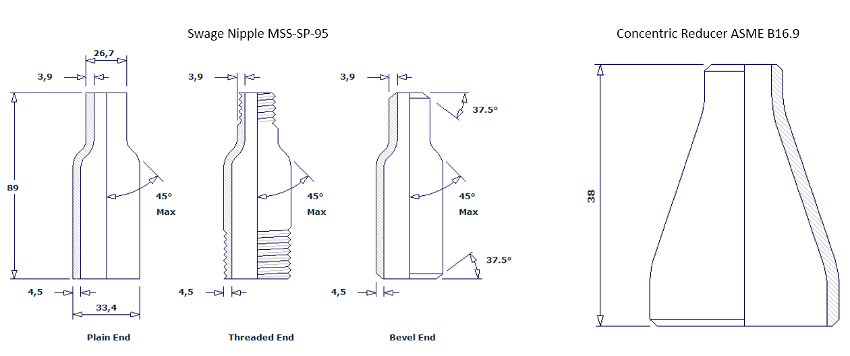

Reducers vS reducing nipples

| Feature | Reducer | Reducing Coupling |

| What it is | Separate pipe fitting | Short pipe connector |

| Shape | Cone-shaped (gradual size change) | Straight tube with stepped bore |

| Length | Longer (4″-12″ typical) | Shorter (2″-4″ typical) |

| Flow Change | Smooth, gradual size transition | Sudden size jump |

| Pressure Drop | Lower (gentle transition) | Higher (abrupt change causes turbulence) |

| Installation | Welded/bolted between pipes | Screwed/socket-welded at pipe ends |

| Space Needed | More space required | Fits tight spaces |

| Repairable? | Hard to replace (welded systems) | Easy to unscrew/replace |

| Common Uses | • Pump in/outlets • Main pipelines | • Valve connections • Equipment hookups • Quick repairs |

FAQ

Q: What are the main differences between concentric and eccentric reducers?

Concentric reducers are symmetrical and well suited for liquid flow, ensuring even distribution and minimizing turbulence.

Eccentric reducers, on the other hand, have edges that run parallel to the pipe, preventing cavitation for gases and low-density fluids when flowing horizontally.

Q: How do I determine the right size reducer for my piping system?

Measure the ID and OD of the existing pipe and match them to the specifications of the reducer.

Consider flow requirements and ensure the material is compatible with the fluid or gas being conveyed.

Q: What materials are commonly used for pipe reducers?

Common materials include carbon steel, stainless steel, PVC, copper, and other alloys. The choice depends on the pressure, temperature, and chemical environment of the application.

Q: Will improperly installed reducers affect system performance?

Yes, improper installation can lead to leaks, pressure drops, and system failures. Ensuring proper alignment, proper fastening, and material compatibility are critical to achieving optimal performance.

Summary

The article explains the reducer in detail, and we have a deeper understanding of the reducer.

In actual engineering projects, choosing the right reducer type and reducer specifications is the key to achieving safe and efficient operation of pipelines.

If you want to learn more about professional knowledge of pipe fittings, please subscribe.