Detailed explanation of high-pressure flange knowledge: Purchasing guide for the world’s top 500 companies

Table of contents

- Preface

- What is a high-pressure flange

- Standard table for flange pressure level classification

- Application of flange pressure level

- Dimensions and specifications of high-pressure flanges

- Material of high-pressure flanges

- Advantages of high-pressure flanges

- High-pressure flanges VS low-pressure flanges

- FAQ

- Summary

Preface

In some extreme industrial environments, high-pressure flanges are widely used. Understanding some of the characteristics of high-pressure flanges can help us better choose flanges suitable for the project.

Metleader found in cooperation with some large international pharmaceutical companies that high-pressure flanges play a very important role and are related to the safe operation of the entire project, and buyers also have very professional knowledge of high-pressure flanges.

Today we have sorted out detailed knowledge about high-pressure flanges, hoping to help companies better understand this product.

What is a high-pressure flange

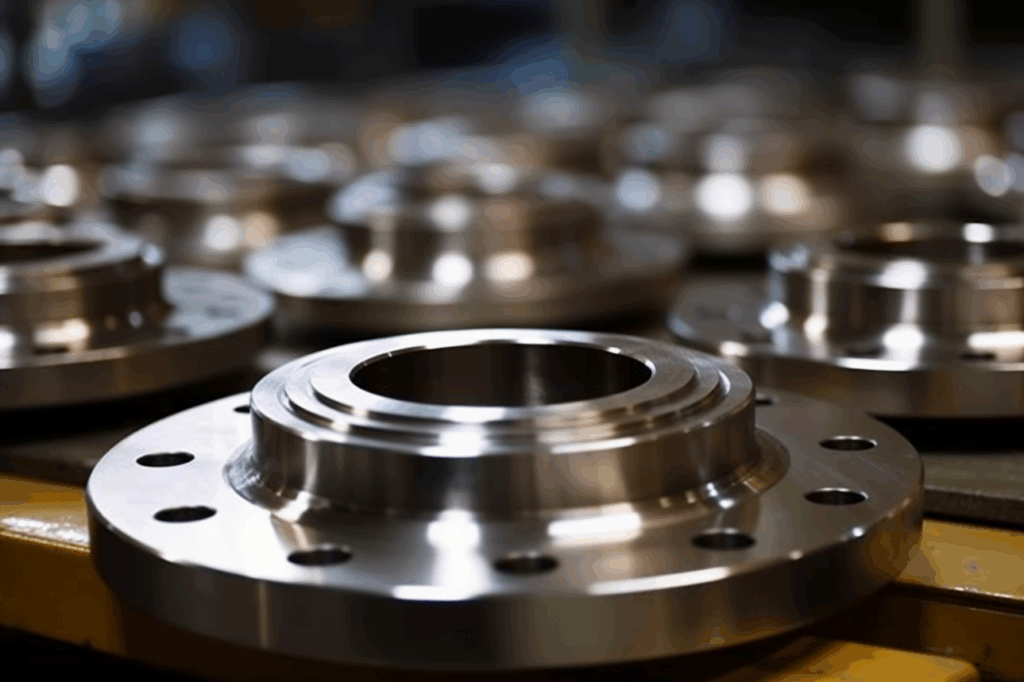

High-pressure flange is a disc-shaped part with the uses of equipment connection, connection, pipeline connection, support, easy disassembly, etc.

It has a long service life, good stability, corrosion resistance, high reliability, and high temperature resistance.

It can be used for support, equipment connection, connection, pipeline connection, sealing, etc. It is a flange with high quality and low price.

Standard table for flange pressure level classification

| Serial No. | Pressure Class | Pressure (MPa) |

| 1 | PN0.25 | 0.25 |

| 2 | PN0.6 | 0.6 |

| 3 | PN1.0 | 1.0 |

| 4 | PN1.6 | 1.6 |

| 5 | PN2.5 | 2.5 |

| 6 | PN4.0 | 4.0 |

| 7 | PN6.3 | 6.3 |

| 8 | PN10 | 10.0 |

| 9 | PN16 | 16.0 |

| 10 | PN25 | 25.0 |

| 11 | PN32 | 32.0 |

| 12 | PN40 | 40.0 |

| 13 | PN63 | 63.0 |

| 14 | PN100 | 100.0 |

Application of flange pressure level

Pipe flanges with different pressure levels are suitable for different occasions. Generally speaking, the higher the pressure level, the larger the size and weight of the flange, and the wider the scope of use.

- PN0.25~PN1.0

These pressure levels are suitable for general industrial and civil pipelines, such as tap water, gas, heating, etc. - PN1.6~PN6.3

These pressure levels are suitable for some high-pressure and high-temperature pipelines, such as petroleum, chemical, metallurgy and other industries. - PN10~PN100

These pressure levels are suitable for pipelines with higher pressure and larger diameters, such as nuclear power plants, large chemical plants, etc.

Dimensions and specifications of high-pressure flanges

In terms of nominal pressure, the common ones are 10MPa, 16MPa, 20MPa, 25MPa, 32MPa, etc.

The nominal diameter usually starts from DN15 and gradually increases, such as DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, etc.

For high-pressure flanges commonly used in chemical, petroleum and other industries, their thickness also has corresponding standards.

For example, for some high-pressure flanges with a nominal pressure of 25MPa, the neck thickness may be around 20-30mm, and the sealing surface width is about 14-20mm, etc.

Material of high-pressure flanges

The main materials of flange high pressure flange are carbon steel, alloy steel, stainless steel and so on.

Advantages of high-pressure flanges

The advantages of high-pressure flange products are introduced as follows:

- Easy to maintain

The high-pressure flange is easy to disassemble and suitable for equipment and pipelines that need to be frequently cleaned, repaired or replaced. It is convenient for maintenance personnel to maintain and reduce downtime and maintenance costs. - Strong pressure bearing capacity

The structural design of the high-pressure flange gives it a strong pressure bearing capacity and can adapt to the needs of high-pressure working environments. It performs well in pipeline connections with high temperature, high pressure and corrosive media, ensuring the long-term stable operation of the pipeline system. - Tight connection

The high-pressure flange connects two high-pressure flanges tightly together through fasteners such as bolts to form a firm mechanical connection to ensure a stable connection between the pipeline and the equipment. - Good sealing

The high-pressure flange adopts the principle of face sealing, and fills the unevenness on the sealing surface with a gasket to achieve effective sealing, prevent fluid leakage, and ensure safe and stable operation during the production process. - Economical

The manufacturing cost of the high-pressure flange is relatively low, and it is easy to assemble by fixing methods such as screws or nuts, which improves production efficiency and reduces production costs.

High-pressure flanges VS low-pressure flanges

| Feature | High-Pressure Flange | Low-Pressure Flange |

|---|---|---|

| Pressure Rating | ≥ 150 psi (e.g., Class 600, 900, 1500) | < 150 psi (e.g., Class 150) |

| Thickness | Thick body | Thin body |

| Material | Strong alloys (SS 316, Cr-Mo steel) | Mild steel, cast iron |

| Bolt Holes | More bolts (8-16 holes) | Fewer bolts (4-8 holes) |

| Bolt Size | Large bolts (high tightening force) | Smaller bolts |

| Sealing | Metal gaskets (RTJ type) | Soft gaskets (rubber, fiber) |

| Surface Finish | Smooth machined face | Rough surface (sand cast) |

| Weight | Heavy | Light |

| Cost | Expensive (2-5× higher) | Low cost |

| Used In | • Oil/gas wells • Steam boilers • Reactors | • Water pipes • Air systems • Drain lines |

FAQ

Which type of flange is used in high pressure and temperature service?

Ring Joint Face (RTJ): Used in high-pressure and high-temperature processes, this face type features a groove in which a metal gasket sits to maintain the seal. Tongue and Groove (T&G): These flanges feature matching grooves and raised sections.

Which type of flange is most likely to be used in high pressure applications?

Weld neck flanges are often used for applications where high pressure is a factor. The inside diameter of the flange is designed to match the pipe’s inside diameter. Weld Neck Pipe flanges with a hub have published specifications that range from 1/2″ thru 96″.

What is the difference between API and ASME flanges?

ANSI/ASME flanges are designed for high-precision applications and are manufactured to strict tolerances. API flanges, on the other hand, are designed for oil and gas drilling and production applications and are manufactured to API 6A standards.

What type of gasket is typically found in high pressure rated flanges?

Semi-metallic gaskets are designed for the operating conditions found in most high-pressure applications. They are typically used on raised face, male-and-female, and tongue-and-groove flanges.

Summary

Through this article, we have learned the detailed knowledge of high-pressure flanges, including its definition, characteristics, applications, standards and product advantages.

As one of the largest flange manufacturers in China, Metleader has been providing excellent flange products for Fortune 500 companies and has been recognized by the market.

Through this article, if you want to know more about our products, please contact us.

If you like this type of professional knowledge, please subscribe to our Youtube or LinkedIn platform.