How to choose the right pipe flange

Table of contents

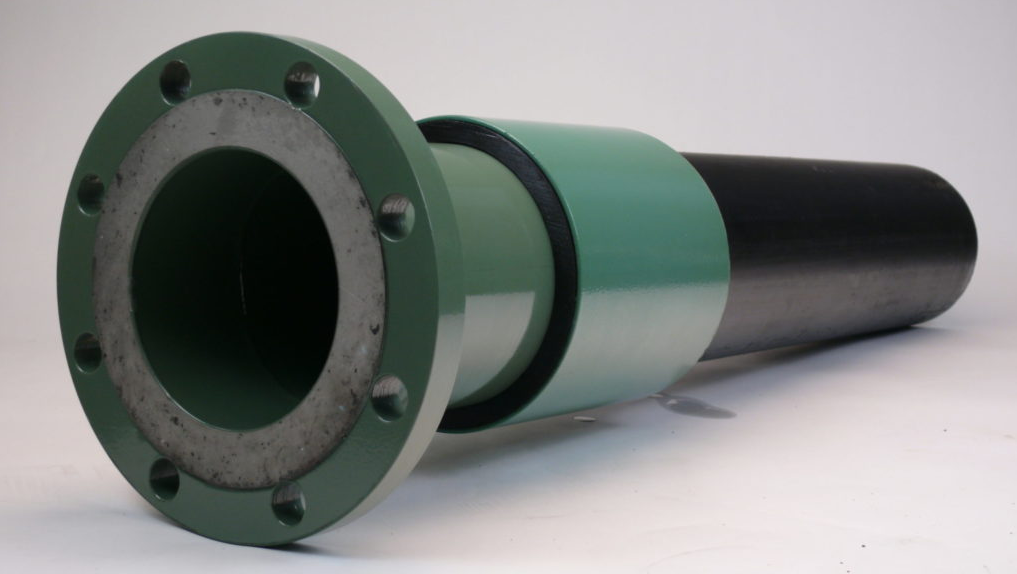

Flange is an important component for connecting pipes, valves, and equipment, and is one of the essential parts in pipeline engineering.

When selecting and installing flanges, many factors need to be considered, such as pressure, temperature, medium, etc. Let’s take a closer look at flange specifications and purchase precautions.

What are the flange specifications

American standards

Flange specifications in the United States are mainly divided into two standards: ASME B16.5 and ASME B16.47. The ASME B16.5 standard is mainly applicable to flanges from 1/2 inch to 24 inches, while the ASME B16.47 standard is mainly applicable to large flanges from 26 inches to 60 inches.

European standards

The flange specifications in Europe are mainly divided into three standards: EN1092, DIN and BS4504.

The EN1092 standard is mainly applicable to flanges from DN15 to DN2000, while the DIN standard is mainly applicable to flanges from DN10 to DN4000, and the BS4504 standard is mainly applicable to flanges from DN10 to DN4000.

Japanese standards

Flange specifications in Japan are mainly divided into two standards: JIS and KS. The JIS standard is mainly applicable to flanges from DN10 to DN2000, while the KS standard is mainly applicable to flanges from DN10 to DN2000.

Notes on flange selection

Selecting a suitable flange requires considering the following aspects:

Influence of working conditions

When selecting a suitable flange, the first thing to consider is the working conditions of the pipeline system. This includes working pressure, working temperature, working medium, working environment and other factors.

These factors are important factors affecting the selection. Different working conditions require different flanges.

For example, high-strength and corrosion-resistant flanges should be selected under high temperature and high pressure working conditions.

Influence of medium properties

The properties of the medium are also an important factor affecting the flange selection. Different media have different requirements for the material and sealing of the flange.

For example, for highly chemically corrosive media, flanges made of materials with excellent corrosion resistance should be selected to avoid medium corrosion affecting equipment performance.

Influence of connection methods

Different pipe connection methods also require different flanges. For example, flange connection, threaded connection, clamp connection, etc.

need to be used in conjunction with the butt-jointed pipe system to ensure that the connection is stable and reliable without leakage or other problems.

Choose the right material

Choosing the right material is also an important factor in selecting the right flange. Different materials correspond to different media properties and working conditions.

Common materials include carbon steel, stainless steel, cast iron, copper, etc. Choose the right material based on factors such as the media, working conditions and connection methods of the pipeline system.

Summary

The selection of suitable flanges requires comprehensive consideration of factors such as the working conditions of the pipeline system, the properties of the medium, the connection method and the material.

Only by selecting a reasonable flange can the normal operation and safety performance of the pipeline system be ensured.

When selecting a suitable flange, it is necessary to compare, analyze and evaluate it in detail according to the actual working conditions, follow the specifications and refer to the reference materials.