Hot Rolling VS Cold Rolling of Steel Pipe

Table of Contents

Hot rolling and cold rolling are both processes for forming steel plates or profiles, and they have a great impact on the structure and performance of steel.

Hot rolling is the main method of steel rolling, and cold rolling is usually only used to produce small-sized steel and thin plates with precise dimensions.

Differences between hot rolling and cold rolling

Hot rolling and cold rolling are both ways of metal processing, and the same is true when processing steel pipes. Hot rolling is processed in a hot state, while cold rolling is processed at room temperature.

Different processing temperatures

Hot rolling requires heating the steel to a certain temperature (usually around 1000-1300°C) and then pressing it through tire rollers to obtain the desired shape of the product.

Cold rolling is processed at room temperature, so the steel strength is relatively high.

Different finished product performance

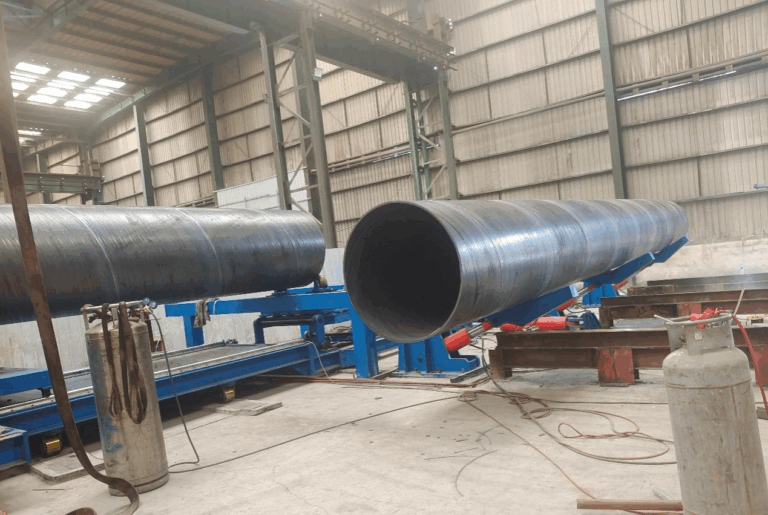

Since the hot-rolled steel pipe is in a hot processing state, its surface is relatively rough and may be somewhat uneven overall.

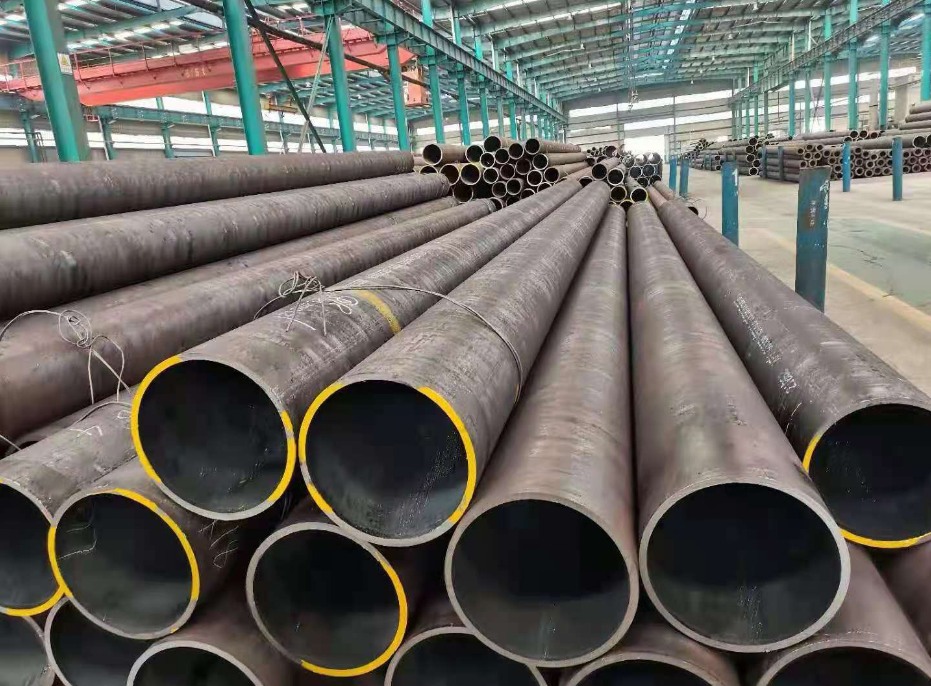

The surface of the finished cold-rolled steel pipe is relatively smooth and has better overall smoothness.

Different application scenarios

Hot-rolled steel pipes are widely used in construction, bridges, petroleum, chemical and other industries, mainly for the manufacture of large structural parts; while cold-rolled steel pipes are mainly used in the manufacture of automobiles, electrical appliances and some precision instruments, and are also commonly used in industries such as home decoration.

Purposes of hot rolling and cold rolling

Purposes of hot-rolled steel pipes

①Hot-rolled steel pipes are widely used in the field of construction engineering, such as building structures, large span frames, underground engineering, petroleum, chemical industry, shipbuilding and other fields.

②Hot-rolled steel pipes are also commonly used in the automotive field, mainly used to manufacture body structures and improve vehicle strength and flexibility.

③Hot-rolled steel pipes are also used in a wide range of industrial production, such as boilers and pressure vessels, wheels, shafts, brackets, machine manufacturing, etc.

Purposes of cold-rolled steel pipes

①The automotive industry is one of the main application areas of cold-rolled steel pipes.

Cold-rolled steel pipes are widely used in the interior and exterior decoration of automobiles, as well as automobile rims, frame structures, and chassis.

②Cold-rolled steel pipes are also commonly used in home decoration, such as wardrobes, product racks, hotel furniture, etc.

Summary

Hot rolling and cold rolling are very important steps in the production process of steel pipes.

In the production process, hot-rolled steel pipes and cold-rolled steel pipes are widely used in construction, bridges, petroleum, chemicals, automobiles, electrical appliances, home decoration and other fields.

For different scenarios and requirements, we can choose different types of steel pipes to meet the needs.