Introduction to Spiral Steel Pipe: A Procurement Guide for Businesses

Contents

- Introduction

- What is spiral steel pipe?

- Classification of spiral steel pipe

- Specifications of spiral steel pipe

- Standards for spiral steel pipe

- Structure and characteristics of spiral steel pipe

- Applications of spiral steel pipe

- How to choose high-quality spiral steel pipe

- Spiral steel pipe vs. seamless steel pipe

- Top 10 steel pipe manufacturers in China

- Summary

Introduction

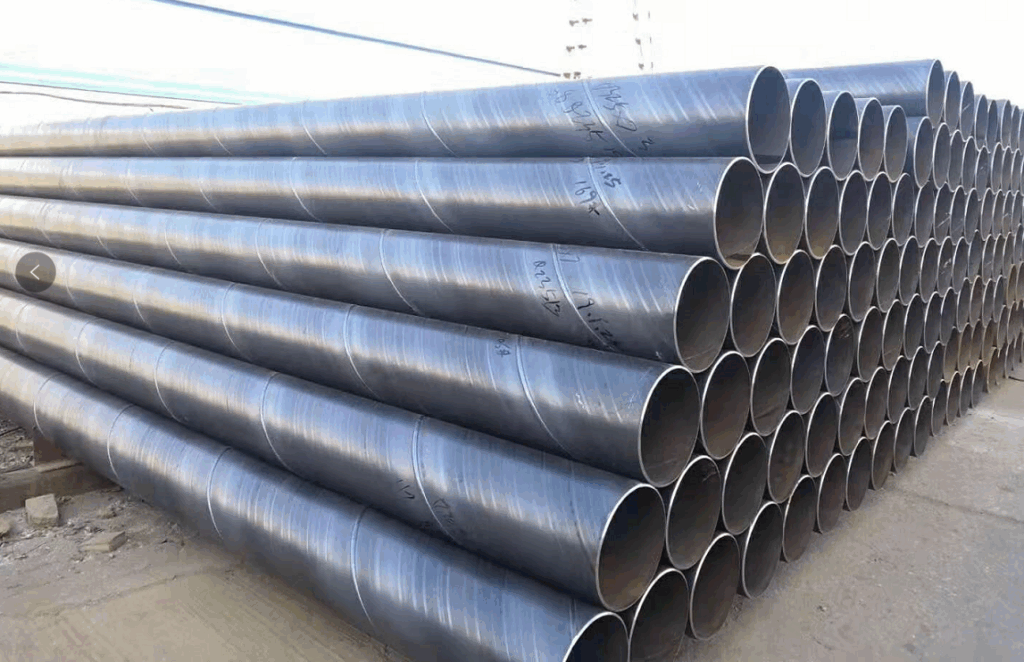

Spiral steel pipe is widely used in industry. With its unique spiral weld structure and excellent overall performance, it has become the “steel artery” supporting modern infrastructure.

Produced through a spiral forming process, this welded steel pipe, with its high strength, high toughness, and easy processing, is being deeply integrated into national strategic sectors such as energy transmission, water conservancy projects, and urban construction, becoming an indispensable key material in the industrialization process.

This article will focus on the basics of spiral steel pipe, which will help companies better procure the right steel pipe.

For more information on steel pipe, please follow us on YouTube and LinkedIn.

What is spiral steel pipe?

Spiral steel pipe, also known as spiral welded pipe, is made by rolling low-carbon structural steel or low-alloy structural steel strip into a tube blank at a spiral angle and then welding it.

Classification of spiral steel pipe

Spiral steel pipe is a pipe made of steel coils and welded through a spiral forming process. Its classification is mainly based on the following dimensions:

Classification by material

Carbon steel spiral pipe: The representative model is Q235B, with a tensile strength of ≥375 MPa and low cost, widely used for low-pressure fluid transportation.

Low-alloy high-strength steel spiral pipe, such as L245 (API 5L), is added with elements such as chromium and molybdenum, with a tensile strength of ≥415 MPa and suitable for high-pressure oil and gas pipelines.

Stainless steel spiral tube: Made of 304 or 316 (ASTM A312), it has strong corrosion resistance and is used in the chemical and food industries.

Classification by production process

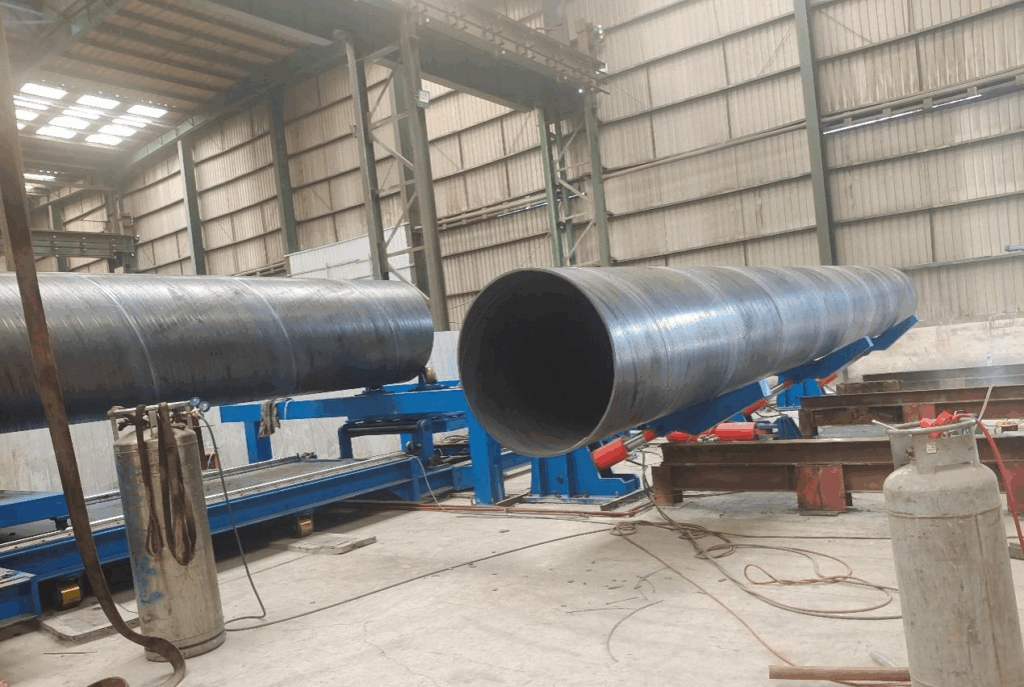

SAW: Features deep welds and high strength, capable of producing steel pipes with diameters ranging from 219mm to 3500mm (referring to SY/T 5037).

ERW: Offers high production efficiency but lower weld strength, primarily used in non-pressure-bearing applications such as construction scaffolding.

Classification by application

Spiral pipe for transportation: Requires API 5L certification and a pressure bearing capacity of ≥6.3 MPa. It is used in long-distance oil and natural gas pipelines.

Structural spiral pipe: Conforms to GB/T 13793 standard and is commonly used in bridge piers and wind turbine tower support structures.

Specifications of spiral steel pipe

Model (#15703170555#)

| Nominal diameter (DN, mm) | OD(mm) | wall thickness (mm) | length (m) | Material | Applicable pressure level |

| 200 | 219.1 | 5.0~12.0 | 6~12 | Q235B, L245 | Low pressure ~ medium pressure |

| 300 | 323.9 | 6.0~14.0 | 6~12 | Q345B, L290 | Medium pressure |

| 400 | 406.4 | 6.0~16.0 | 6~12 | Q345R, L360 | Medium and high voltage |

| 500 | 508.0 | 8.0~20.0 | 6~12 | X42, X52 | High pressure |

| 600 | 610.0 | 8.0~22.0 | 6~12 | X60, X65 | High pressure |

| 800 | 813.0 | 10.0~26.0 | 6~12 | X70, X80 | High pressure |

| 1000 | 1016.0 | 12.0~30.0 | 6~12 | X80, X100 | Ultra-high voltage pipelines |

| 1200 | 1220.0 | 14.0~32.0 | 6~12 | X100, L485 | Marine Engineering |

Standards for spiral steel pipe

As an important industrial pipe material, spiral steel pipe’s international standards primarily cover material quality, dimensions, manufacturing processes, and testing requirements. The following are the core international standards:

- API Spec 5L: This standard for oil and natural gas pipelines specifies two quality grades, PSL1 and PSL2, covering steel grades from A25 to X120, emphasizing chemical composition, mechanical properties, and non-destructive testing requirements.

- ISO 3183: Highly compatible with API 5L, it is divided into three parts, ISO 3183-1/2/3, and provides additional technical requirements for different operating conditions, such as onshore, offshore, and highly acidic environments, such as resistance to hydrogen-induced cracking (HIC).

- ASTM A252: Suitable for spiral welded pipe used in pile foundations, it focuses on compressive strength and ductility. Common steel grades are Gr1-Gr3. 4. EN 10217: For pressure-bearing welded pipes. EN 10217-3 specifically covers the technical requirements for spirally welded pipes, covering steel grades P235TR2 to P460TR2.

- AS/NZS 1579: For high-strength structural pipes, emphasizing toughness indicators such as the Charpy impact test.

Structure and characteristics of spiral steel pipe

The main features of spiral hoses are as follows:

- High strength and high load-bearing capacity;

- Excellent pressure resistance, suitable for conveying high-pressure fluids;

- High welding quality, uniform welds, and few defects;

- Simple manufacturing process and high production efficiency;

- Long service life.

Applications of spiral steel pipe

Spiral pipes are primarily used in the following areas:

- Liquid transportation in the oil, natural gas, and chemical industries;

- Municipal drainage and water supply pipelines;

- Pipes for building structures;

- Transportation projects such as bridges and tunnels.

How to choose high-quality spiral steel pipe

When choosing high-quality spiral hose, consider the following aspects:

- Whether the manufacturer has complete qualifications and relevant certifications;

- Whether the material meets national standards and the quality is up to standard;

- Whether the welds are uniform and the surface quality is smooth;

- Whether the dimensions are accurate and meet the requirements.

Spiral steel pipe vS seamless steel pipe

| Parameter | Spiral Welded Pipe (SAW) | Seamless Steel Pipe (SMLS) |

| Manufacturing Process | Helical seam welding of coiled steel strips (JCOE) | Extrusion/piercing of solid billets (rotary or plug mill) |

| Production Standards | API 5L, ASTM A139, EN 10217-1 | API 5L, ASTM A106/A53, EN 10216-1 |

| Wall Thickness Range | 5-25mm (typical), up to 40mm | 1-120mm (broader range) |

| Diameter Range | 250-3500mm (large diameters achievable) | 10-1200mm (limited by billet size) |

| Weld Inspection | 100% X-ray/ultrasonic testing (mandatory) | Not applicable (no seam) |

| Residual Stress | Higher (due to welding thermal effects) | Lower (uniform grain structure) |

| Ovality Tolerance | ±1.0% of nominal diameter | ±0.5% of nominal diameter |

| Surface Finish | Visible spiral weld bead (requires grinding) | Smooth, uniform surface |

| Pressure Rating | Lower (80% of equivalent seamless pipe) | Higher (full pressure capability) |

| Cost Efficiency | 30-50% cheaper for large diameters | 20-40% more expensive |

| Lead Time | Shorter (continuous production) | Longer (batch processing) |

| Common Applications | Water transmission, piling, structural supports | High-pressure/temperature services, OCTG |

| Material Utilization | 95-98% (minimal scrap) | 75-85% (significant cropping loss) |

| Corrosion Resistance | Weld zone vulnerable to preferential corrosion | Uniform corrosion resistance |

| Dimensional Stability | Requires frequent caliber adjustment | Consistent throughout length |

Top 10 steel pipe manufacturers in China

| Company Name | Location | Core Products & Specializations |

| Tianjin Pipe (TPCO) | Tianjin | – World’s largest seamless pipe producer – OCTG pipes (API 5CT) – High-alloy pipes for sour service |

| Baosteel Special Pipe | Shanghai | – Premium boiler tubes (ASTM A213) – Nuclear-grade pipes (RCC-M standard) – U-shaped heat exchanger tubes |

| Beijing Metleader Pipeline | Beijing | – Anti-corrosion coated pipes (3LPE/FBE) – Precision cold-drawn alloy pipes – Clad pipes for chemical industry |

| Jiangsu Changbao Steel Tube | Jiangsu | – High-frequency ERW pipes (API 5L X80) – Automotive precision tubes – Hydraulic cylinder tubes |

| Zhejiang JIULI Hi-Tech Metals | Zhejiang | – Nickel-based alloy pipes (Inconel 625) – Super duplex stainless pipes – Seamless titanium tubes |

| Wuxi Seamless Oil Pipe | Jiangsu | – Drill pipes & casings (API 5DP/5CT) – High-pressure boiler tubes (ASTM A335 P91/P92) |

| Hengyang Valin Steel Tube | Hunan | – Large-diameter spiral welded pipes (EN 10219) – Subsea pipeline coatings – Structural hollow sections |

| Zhangjiagang Huaye Steel Tube | Jiangsu | – LSAW pipes for oil/gas transmission – JCOE process pipes – Offshore platform piles |

| Shandong Molong Petroleum | Shandong | – OCTG premium connections (VAM, TMK) – CRA-lined pipes – Coiled tubing units |

| Anhui Tianda Oil Pipe | Anhui | – ERW well casing pipes – Galvanized conduit pipes – API 5CT P110 grade pipes |

Summary

The above is the basics of spiral steel pipes. We hope this helps you with your purchase.

Metleader specializes in producing spiral steel pipes, including stainless steel pipes, seamless steel pipes, anti-corrosion and thermal insulation steel pipes, oil casing, and carbon steel pipes.

Our products are diverse, with complete specifications, and large-diameter steel pipes can be customized.

If you would like to purchase spiral steel pipes, please contact us.

Our sales manager will respond within 24 hours and provide a complete solution based on your project.