A105 Flange Comprehensive Analysis: Material, Specifications, and Applications

Contents

- Preface

- What is an A105 flange?

- What is an A105 flange?

- Applications of ASTM A105

- Characteristics of A105 flanges

- ASTM A105 vs. ASTM A106

- Summary

Preface

In industrial production and machinery manufacturing, flanges, as crucial components connecting pipelines and equipment, directly affect the safety and operational efficiency of the entire system.

Among the many types of flanges, A105 weld neck flanges are widely used in various industrial applications due to their excellent mechanical properties and high corrosion resistance.

Today, we’ll delve into the relevant knowledge about A105 flanges to help you make a better choice.

If you’d like to learn more about flange fittings, you can follow us on YouTube and LinkedIn.

What is an A105 flange?

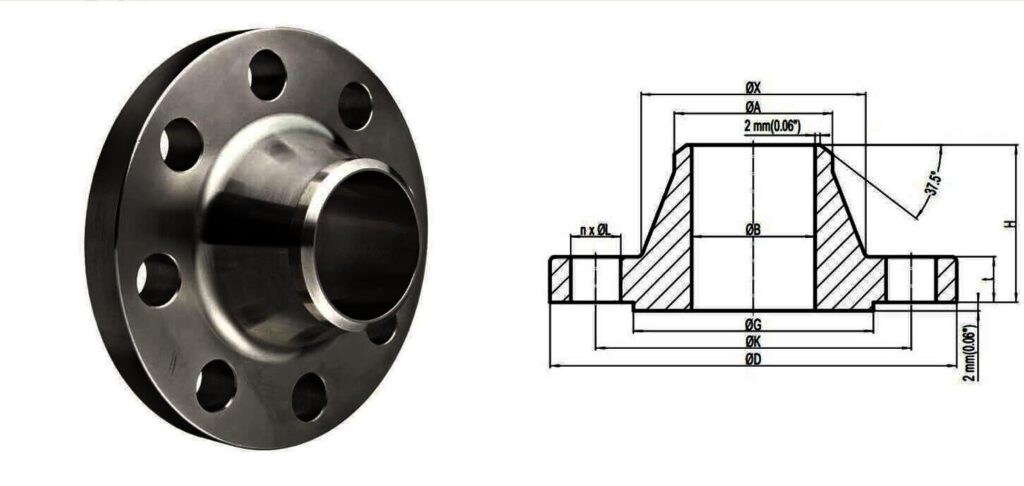

A105 is the material designation for carbon steel forgings used in piping components in the American ASTM standard system.

The corresponding international standard is ASTM A105/A105M, and it is mainly used to manufacture pressure-bearing pipe fittings such as valves and flanges. An A105 flange is a flange that meets this standard.

What is an A105 flange?

Flange A105 is a common carbon steel material, mainly composed of iron and carbon, with small amounts of other alloying elements. A105 material has a moderate carbon content, achieving a good balance between strength and toughness.

A105 is also a material designation, belonging to special steel, a type of cold-forged steel, and a low-carbon steel forging.

Hardness characteristics of an A105 flange

The hardness of flange A105 is typically in the Brinell hardness (HB) range of 150-180.

This hardness level provides it with sufficient strength to withstand pressure while maintaining a certain degree of toughness to prevent brittle fracture. In practical applications, this hardness characteristic allows it to adapt to a variety of working conditions.

Chemical composition of ASTM A105

The main chemical compositions of ASTM A105 carbon steel include:

| Element (Symbol) | C | Si | Mn | P | S | Cu | Ni | Mo | V | Cr |

| Content (%) | ≤ 0.35 | ≤ 0.35 | 0.6 – 1.05 | ≤ 0.040 | ≤ 0.050 | ≤ 0.40 | ≤ 0.40 | ≤ 0.12 | ≤ 0.08 | ≤ 0.30 |

Mechanical properties of ASTM A105

The mechanical properties of ASTM A105 carbon steel include:

Tensile strength: ≥485 MPa;

Yield strength: ≥250 MPa;

Elongation: ≥22%;

Reduction of area: ≥30%;

Hardness: ≤HB187

Applications of ASTM A105

ASTM A105 carbon steel is widely used in:

- Pipeline systems in the petroleum, chemical, and natural gas industries;

- Valves and pipe fittings;

- General industrial applications, especially in applications requiring high pressure resistance;

Characteristics of A105 flanges

Stable Material Properties

A105 steel possesses good strength and ductility, maintaining excellent performance over a wide operating temperature range. Its yield strength and tensile strength both meet industry standards, satisfying the requirements of high-pressure environments.

Good Weldability

A105 steel exhibits good weldability, allowing for various welding methods. Post-weld performance is stable and resistant to cracking or deformation.

Corrosion Resistance

While A105 steel’s inherent corrosion resistance is not as high as stainless steel, its performance can be improved through proper heat treatment and anti-corrosion measures, making it suitable for use in harsher environments.

Cost-Effectiveness

A105 steel has a relatively low cost. When manufactured into flanges, it can meet the needs of industrial production at a reasonable price, balancing performance and economy.

ASTM A105 vs ASTM A106

A105 is a standard for carbon steel forgings used in piping components (such as valves and flanges), while A106 is a standard for seamless steel pipes.

Both are low-carbon steels, but A105 has higher mechanical strength, while A106 is suitable for high-temperature piping systems.

The following are the main differences between the two:

| Feature | ASTM A105 | ASTM A106 |

| Product Form | Forged carbon steel components | Seamless carbon steel pipe |

| Primary Use | Pipe flanges, fittings, valves | High-temperature service piping |

| Service Type | Pressure-containing parts | Pressure-conveying lines |

| Parameter | ASTM A105 | ASTM A106 |

| Manufacturing | Forging + heat treatment | Hot-finished or cold-drawn seamless |

| Temperature Range | -29°C to 425°C | -29°C to 540°C (Grade B) |

| Grades | Single grade only | Grade A, B, C (increasing strength) |

| Testing Focus | Tensile, hardness, impact | Tensile, bend, hydrostatic |

Summary

As we’ve seen from the above introduction, the widespread use of A105 flanges stems from their perfect combination of ideal material properties and suitable hardness.

This combination makes them an ideal choice for piping systems, meeting strength requirements while facilitating processing and installation.

Understanding the basics of A105 flanges can help us better select the right flange, ensuring the safety and efficiency of our projects.

For more information on flange pricing and catalogs, please contact us.