Carbon Steel Pipe VS Alloy Steel Pipe

Contents

- What are carbon steel pipes and alloy steel pipes

- How to distinguish carbon steel pipes from alloy steel pipes

- Differences in welding alloy steel and ordinary carbon steel pipes

- Comparison of performance characteristics of carbon steel pipes and alloy steel pipes

- Conclusion

The difference between welding alloy steel pipes and ordinary carbon steel pipes is that alloy steel pipes require more welding parameters and special measures during welding, and have higher requirements on materials and quality.

At the same time, the weld performance also requires special attention.

What are carbon steel pipes and alloy steel pipes

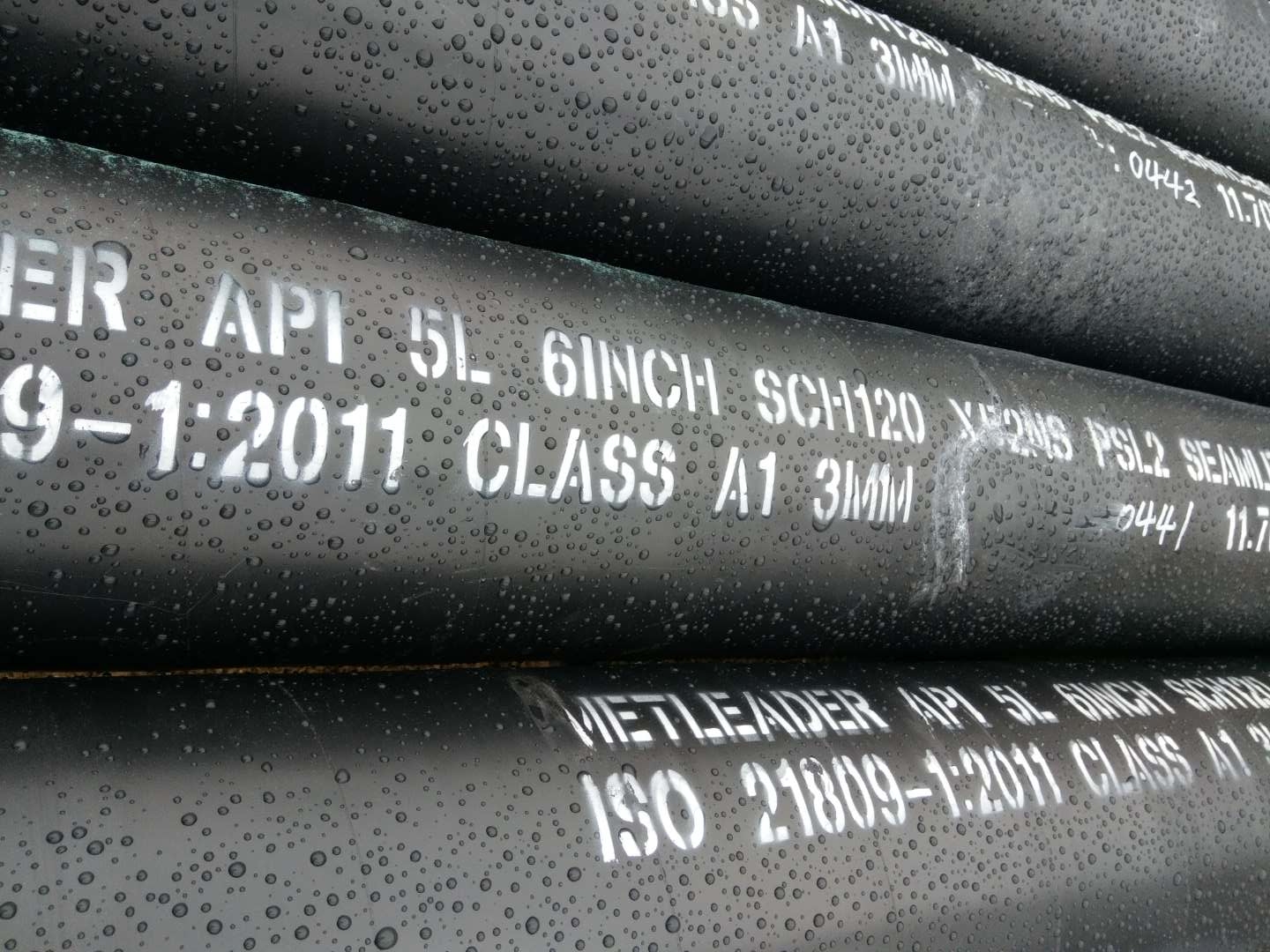

Carbon steel pipe is a steel pipe made of a mixture of carbon and iron, with the carbon content not exceeding 2.11%.

Alloy steel pipe is a steel pipe made of a mixture of iron, carbon and other alloying elements (such as chromium, molybdenum, manganese, titanium, etc.).

How to distinguish carbon steel pipes from alloy steel pipes

- Chemical composition analysis: By analyzing the carbon, chromium, molybdenum and other elements in the steel pipe, it can be determined whether the steel pipe is an alloy steel pipe.

- Hardness test: Since other elements are added to the alloy steel pipe, the hardness is usually higher than that of the carbon steel pipe, so it can be judged by hardness test.

- Magnetic test: Carbon steel pipe is a non-magnetic material, while most alloy steel pipes are magnetic materials, so the two can be distinguished by magnetic test.

- Observe the appearance: Alloy steel pipes are usually brighter and smoother than carbon steel pipes, and have better surface quality.

Differences in welding alloy steel and ordinary carbon steel pipes

Different welding parameters

During the welding process, alloy steel pipelines require more welding parameters, which are more complicated than ordinary carbon steel pipelines.

Welding parameters usually refer to welding current, voltage, welding speed, manual or automatic welding, etc., and these parameters have a great influence on welding quality and effect.

Higher material quality requirements

Since the chemical composition of alloy steel is more complex than that of ordinary carbon steel, its material quality requirements are higher.

When welding, special attention should be paid to the selection of electrode and the quality of arc melting to ensure the quality of the weld.

Weld performance requires special attention

Compared with ordinary carbon steel, the problems of porosity and deformation are more likely to occur in the weld of alloy steel. These problems are particularly obvious when welding alloy steel pipes with uneven thickness.

Therefore, special measures need to be taken during welding to ensure the performance of the weld, such as preheating before welding and subsequent recovery welding.

Comparison of performance characteristics of carbon steel pipes and alloy steel pipes

- Carbon steel pipes have lower costs, but poorer strength and corrosion resistance.

- In addition to iron and carbon, alloy steel pipes also contain other alloy elements, so their strength, wear resistance, corrosion resistance and other properties are better than carbon steel pipes, but the cost is correspondingly higher.

- Due to the excellent performance of alloy steel pipes, they are widely used in some high-requirement fields such as shipbuilding, nuclear power plant pipelines, aerospace, and chemical industries.

- Carbon steel pipes are still used in ordinary low-requirement fields, such as construction, machinery, petrochemicals, etc.

Conclusion

The difference between the welding of alloy steel pipelines and ordinary carbon steel pipelines is that alloy steel pipelines require more welding parameters and special measures during welding, and have higher requirements for materials and quality.

At the same time, the weld performance also requires special attention.

During the operation, relevant operating procedures must be followed and the welding quality must be strictly controlled to ensure that the weld quality meets the standards.