The most complete introduction to standard oil casing

Contents

- What is oil casing

- Classification of oil pipes

- Common specifications and sizes of oil pipes

- Application scenarios of oil pipes

- Physical properties of oil casing

- Standards of oil casing

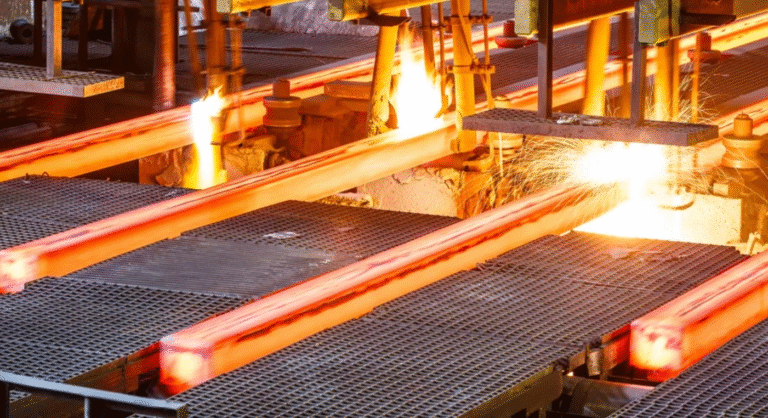

Oil pipe is a kind of pipeline used to transport oil, gas or other chemicals. It is usually made of carbon steel, alloy steel and other materials, and has the characteristics of high temperature resistance, corrosion resistance and good pressure resistance.

What is oil casing

A seamless or welded tube made of high quality steel with both ends finely machined to form tapered threads.

Classification of oil pipes

According to different uses, oil pipes can be divided into several types, such as oil well pipes, reservoir pipes, oil pipelines, gas reservoir pipes, etc.

Among them, oil well pipes are mainly used for drilling operations, reservoir pipes are used for oil production and transmission, and oil pipelines and gas reservoir pipes are used to transport oil and gas.

Common specifications and sizes of oil pipes

The specifications of oil pipes are generally composed of three parameters: outer diameter, wall thickness and length. Depending on the use requirements, there are usually the following specifications:

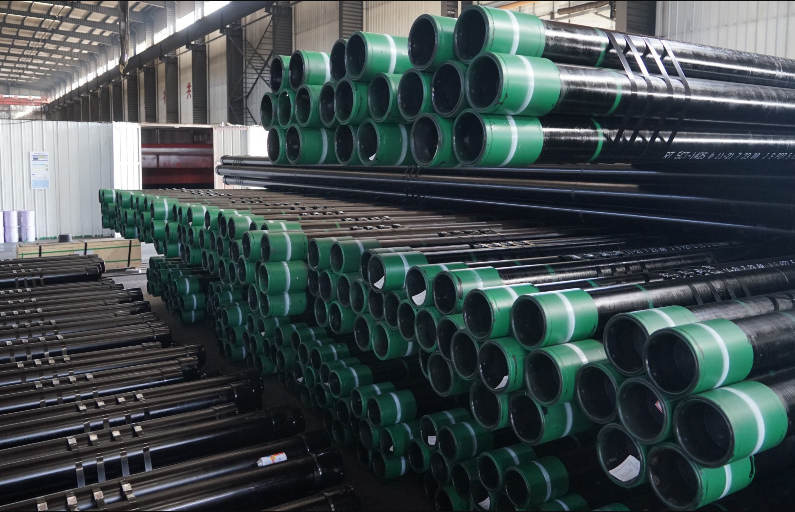

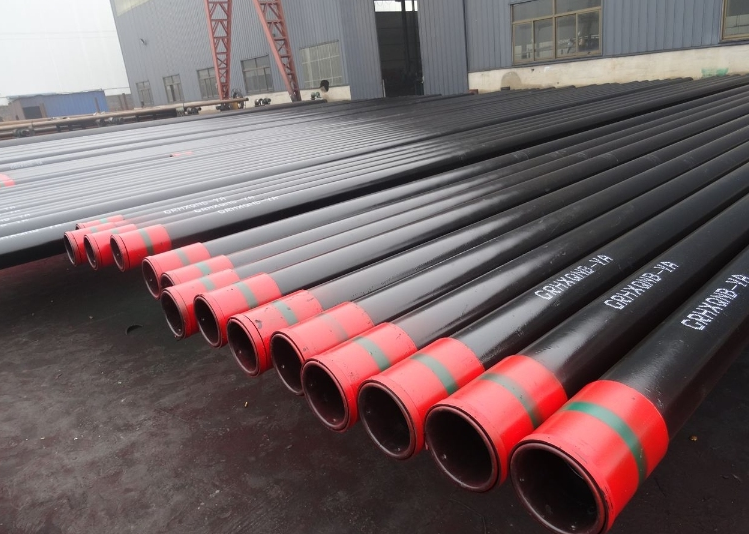

- Casing pipe: The diameter ranges from 4½ to 20 inches, and the wall thickness ranges from 0.205 to 0.875 inches.

- Tubing pipe: The diameter ranges from 1.05 to 4½ inches, and the wall thickness ranges from 0.113 to 0.797 inches.

- Line pipe: The diameter ranges from 2 to 48 inches, and the wall thickness ranges from 0.065 to 0.5 inches.

- Drill pipe: The diameter ranges from 23/8 to 6^5⁄8 inches, and the wall thickness ranges from 0.19 to 0.75 inches.

Application scenarios of oil pipes

- Casing pipes are often used for wellbore support and well wall stability to prevent well wall collapse, and can also isolate different strata in the formation.

- Tubing pipes are mainly used to extract oil from oil wells, and their diameter and thickness need to be reasonably selected based on factors such as well depth and fluid properties.

- Line pipes are used to transport fluids such as oil and natural gas, and usually the specifications are selected based on factors such as transportation distance, fluid properties and pipeline pressure.

- Drill pipes are mainly used for drilling operations, and their specifications and sizes should be reasonably selected based on factors such as well depth, drill bit type, and mud circulation volume.

Physical properties of oil casing

(1) According to SY/T6194-96, flattening test (GB246-97), tensile test (GB228-87) and water pressure test are carried out;

(2) According to the provisions of the American Petroleum Institute API SPEC 5 CT 1988, 1st edition, hydrostatic pressure test, flattening test, sulfide stress corrosion cracking test, hardness test (ASTM E18 or E10 version), tensile test, transverse impact test (ASTM A370, ASTM E23 and related standard versions), grain size determination (ASTM E112 version or other methods).

Standards of oil casing

According to API standards, the outer diameter of the casing ranges from 114.3 mm (4.5 inches) to 508 mm (20 inches), with a total of 14 specifications available.

The API standard clearly specifies the wall thickness range of various specifications of casing, ranging from 5.21 mm to 16.13 mm.

The connecting threads of the casing are all tapered to meet API standards, including short round thread (STC), long round thread (LTC), trapezoidal thread (BTC) and straight thread (XL).

When constructing a casing string, casings with the same outer diameter, the same or different steel grades, and different wall thicknesses are usually connected by couplings to ensure their strength and production requirements.