Analyzing Carbon Steel: Why is Carbon Steel So Widely Used?

Table of contents

- Preface

- What is Carbon Steel?

- Classification of Carbon Steel

- Characteristics of Carbon Steel

- Performances of Carbon Steel

- Classification of Carbon Steel Pipe Fittings

- Applications of Carbon Steel

- Why Carbon Steel is the Most Common

- Advantages of Metleader

Preface

Carbon steel is one of the most widely used metal materials in the industrial field. Due to its superior properties, it is used in many industrial sectors.

Carbon steel pipe fittings are diverse in type and applicable to numerous fields, making them the best choice for many industries.

Metleader is committed to the manufacture of carbon steel pipe fittings, possessing extensive experience and able to provide customers with various types, specifications, and standards.

To learn more about Metleader, please follow us on YouTube and LinkedIn.

What is Carbon Steel?

Carbon steel is an alloy steel, primarily composed of iron and carbon, with smaller amounts of other elements.

Because of varying carbon content, its properties and characteristics will differ.

Classification of Carbon Steel

Carbon steel can be divided into three types based on its carbon content: low-carbon steel, medium-carbon steel, and high-carbon steel.

Low Carbon Steel

Carbon content between 0.12% and 0.30% is often used to manufacture components and parts that do not require high strength.

Medium Carbon Steel

With a carbon content between 0.30% and 0.60%, it is suitable for some parts that require high strength and wear resistance.

High Carbon Steel

The carbon content is above 0.60%. High-carbon steel has very high hardness and wear resistance, but it is also relatively brittle. It is commonly used to manufacture parts that require high hardness, such as cutting tools, springs, and bearings.

Characteristics of Carbon Steel

Carbon steel materials have the following characteristics:

Easy to process: Carbon steel has excellent plasticity and machinability, facilitating machining, sheet metal processing, and welding.

Low cost: Due to the readily available raw materials and simple production process, carbon steel is relatively inexpensive.

Good toughness: Carbon steel possesses excellent toughness and plasticity, while also exhibiting certain tensile strength and hardness.

Strong applicability: Carbon steel has relatively good corrosion resistance, making it suitable for use in various environments.

Performances of Carbon Steel

Mechanical properties

| Property | Typical Range / Value for Low Carbon Steel (e.g., AISI 1020) | Typical Range / Value for Medium/High Carbon Steel (e.g., AISI 1045) | Key Influencing Factors |

| Tensile Strength | 410 – 500 MPa | 570 – 700 MPa (can exceed 1000 MPa with heat treatment) | Carbon content, alloying elements, rolling/forging process, heat treatment (quenching & tempering). |

| Yield Strength | 240 – 350 MPa | 450 – 550 MPa (quenched & tempered) | Similar to tensile strength. Microstructure (ferrite/pearlite/martensite) is decisive. |

| Elongation (Ductility) | 15% – 25% | 10% – 20% (decreases with increasing strength) | Inversely related to carbon content and strength. Higher carbon reduces ductility. |

| Hardness (Brinell HB) | 120 – 180 HB | 200 – 300 HB (can reach 60+ HRC after hardening) | Directly correlated with carbon content and strength. Critical for wear resistance. |

| Impact Toughness (Charpy V-notch at 20°C) | 50 – 100 J | 15 – 40 J (greatly reduced in high-carbon grades without proper tempering) | Carbon content, grain size, inclusion content, and most critically, heat treatment. Low-temperature toughness is a key specification. |

| Fatigue Strength | ~50% of tensile strength | ~40-50% of tensile strength | Surface finish, internal defects, stress concentrations, and corrosion environment significantly affect endurance limit. |

Physical properties

| Property | Typical Value / Characteristic | Engineering Significance |

| Density | 7.85 – 7.87 g/cm³ | Critical for weight calculations in structural design and transportation. |

| Melting Point | ~1425 – 1540 °C (depends on composition) | Determines casting, welding, and heat treatment temperatures. |

| Thermal Conductivity | 45 – 65 W/(m·K) | Affects heat dissipation in applications like forgings, heat exchangers, and during welding (heat-affected zone size). |

| Coefficient of Thermal Expansion | 11 – 13 x 10⁻⁶ /K (20-100°C) | Must be considered in design to accommodate thermal stresses, especially in welded structures or composite materials. |

| Electrical Resistivity | ~0.15 – 0.20 x 10⁻⁶ Ω·m | Higher than copper/aluminum, making it unsuitable as a primary conductor but relevant for welding and electrical grounding. |

| Magnetic Properties | Ferromagnetic at room temperature | Essential for applications in motors, transformers, and magnetic shielding. Retains magnetism below the Curie temperature (~770°C for pure iron). |

| Modulus of Elasticity (Young’s Modulus) | 190 – 210 GPa | A fundamental material constant. Determines stiffness/deflection under load and is largely unaffected by heat treatment or carbon content. |

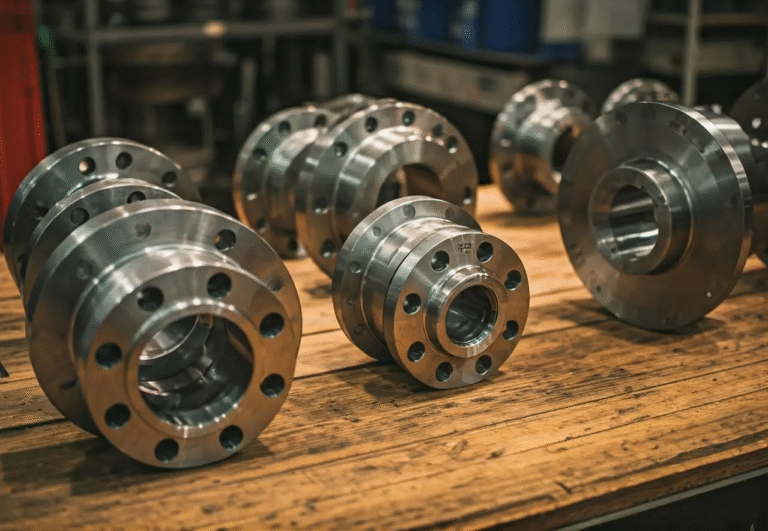

Classification of Carbon Steel Pipe Fittings

Seamless carbon steel pipe fittings: including elbows, tees, crosses, pipe caps, branch pipes, etc.

Welded carbon steel pipe fittings: including welded elbows, welded tees, welded flanges, etc.

Galvanized carbon steel pipe fittings: including galvanized pipes, galvanized flanges, galvanized elbows, etc.

Applications of Carbon Steel

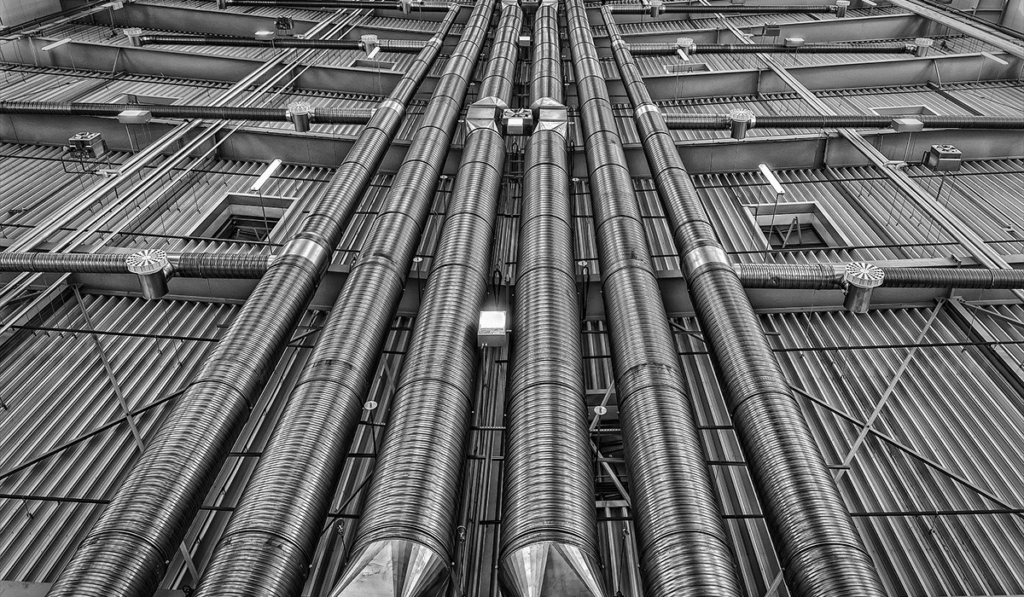

Carbon steel has a wide range of applications, mainly concentrated in the following fields:

- Machinery manufacturing: automotive parts, machine parts, bearing parts, etc.

- Construction: steel pipes, steel plates, etc., used for the support and structure of buildings and bridges.

- Power: support and structure of transmission lines and power towers.

- Petroleum: oil drilling and extraction equipment.

- Chemical: oil tanks, chemical equipment, etc.

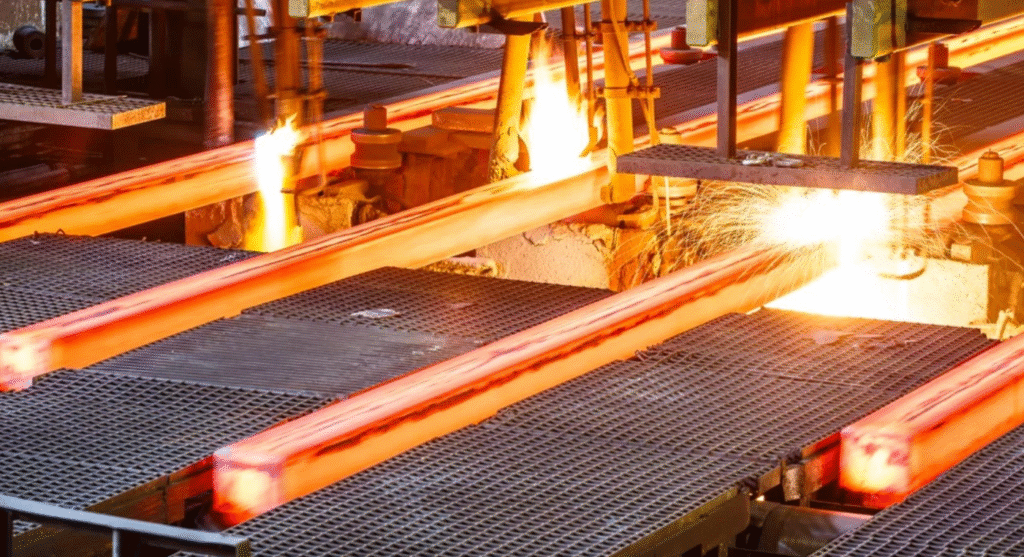

Why Carbon Steel is the Most Common

The most common reason for the application of carbon steel is its low price, good machinability and strength, as well as relatively good toughness and heat resistance.

Due to its high carbon content, carbon steel has good hardness and toughness, allowing it to withstand greater pressure.

Furthermore, it maintains good performance at high temperatures, thus its application is even more widespread in certain specific fields.

Advantages of Metleader

Metleader has been manufacturing carbon steel pipe fittings for 43 consecutive years, possessing extensive manufacturing experience and mature processes that guarantee the quality of our fittings.

Our carbon steel pipe fittings meet standards such as ASTM A53, ASTM A106, DIN 1629, and DIN 17175, satisfying diverse project requirements.

We welcome global partners to visit our factory and support third-party quality testing. If you have purchasing plans, please contact us.