Piping Engineering Solutions: Feasibility of Precast Pipe Fittings

Table of contents

- Preface

- What are precast pipe fittings?

- Advantages of precast pipe fittings

- What do precast pipe fittings include?

- Materials used in precast pipe fittings

- Common standards for precast pipe fittings

- Considerations for selecting precast pipe fittings

- Importance of drawings

- Applications of precast piping

- Summary

Preface

Precast piping is a crucial component of engineering construction, and its quality directly impacts the safety and efficiency of the entire project. Therefore, mastering precast piping techniques is essential.

This article will provide a detailed analysis of precast piping techniques, covering its advantages, structure, materials, standards, and considerations. We hope this article can help you improve your project schedule.

If you would like to learn more about other Metleader piping products, please follow us on YouTube and LinkedIn.

What are precast pipe fittings?

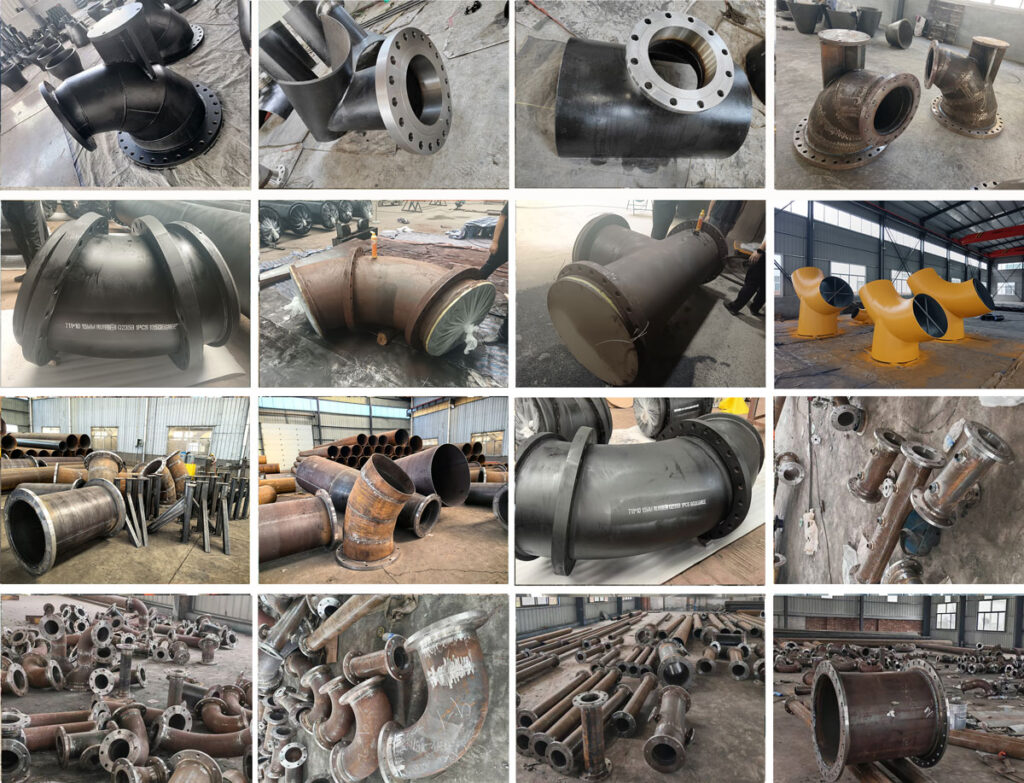

Precast piping refers to piping systems that are prefabricated in a factory according to specific standards and design requirements.

These pipes are typically made of high-quality materials and undergo rigorous testing and inspection to ensure their performance and reliability.

Precast piping can be customized to meet specific needs, including adjusting pipe length, diameter, elbows, flanges, and other fittings to suit the requirements of different engineering projects.

Advantages of precast pipe fittings

Precast pipe fittings offer advantages such as standardization, high efficiency, and cost savings.

Because precast pipe fittings are manufactured in a factory, they significantly improve construction efficiency and shorten the construction period.

Furthermore, the production process of precast pipe fittings strictly adheres to standards and specifications, ensuring the quality and safety of the pipelines.

In addition, precast pipe fittings can reduce construction costs and minimize waste and losses.

What do precast pipe fittings include?

Precast pipe fittings come in a wide variety of types, typically including the following core components:

Pipe body: Serving as the channel for media transportation, it forms the foundation of the pipe fitting.

Pipe fittings: Used to change the direction of the pipeline, branch, reduce diameter, etc., including elbows, tees, crosses, reducers, pipe caps, etc.

Flanges, bolts, and gaskets: Flanges are used to connect pipe fittings to equipment, valves, or other pipe fittings; bolts and gaskets ensure the sealing of the flange connection.

Valves: Such as gate valves, globe valves, ball valves, check valves, etc., used to control the flow of media, cut off or prevent backflow, and can be directly integrated into the pipe fittings.

Support and hanger connections: Pre-welded supports, lifting lugs, etc., facilitating on-site installation of the support system.

Instrument interfaces: Pre-installed thermometer sleeves, pressure gauge interfaces, etc.

Other accessories: Such as connecting pipes for vent valves, drain valves, etc.

Materials used in precast pipe fittings

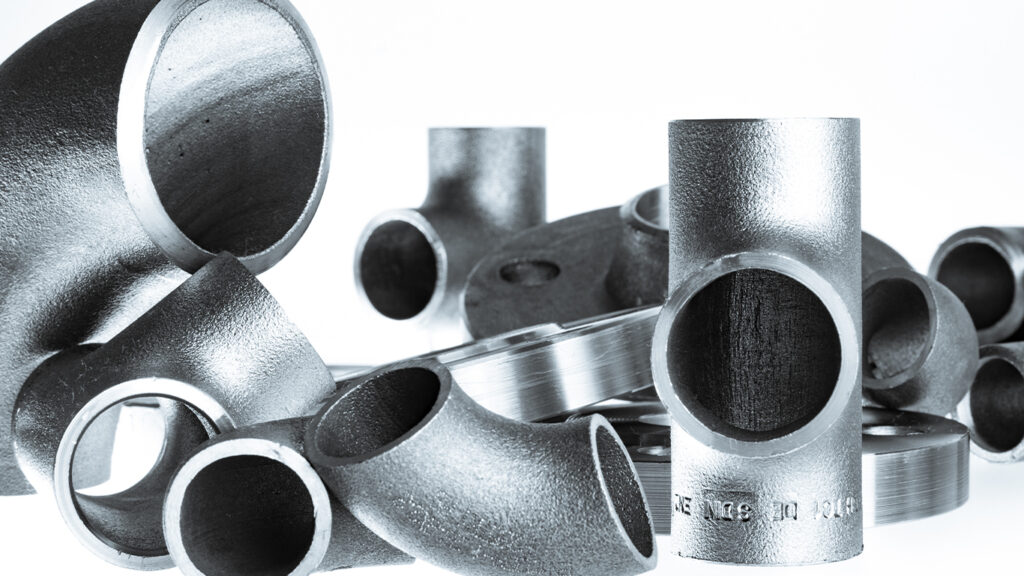

To meet the requirements of different industrial environments, the most common materials for prefabricated pipe fittings include carbon steel, stainless steel, galvanized steel, and alloy steel. In addition, some special metallic and non-metallic materials are also used.

Today we will focus on four common materials:

Carbon steel: High strength, affordable, and weldable; used in oil, gas, and high-pressure systems (e.g., ASTM A53, A106).

Stainless steel: Excellent rust and corrosion resistance; ideal for food, medical, chemical, and harsh environments (e.g., 304, 316, duplex stainless steel).

Galvanized steel: Steel surface coated with zinc to enhance its corrosion resistance.

Alloy steel: High-temperature chromium-molybdenum steel (e.g., P11, P22, P91).

Common standards for precast pipe fittings

ASME B31.3: Process piping design pressure ≥ 1.1 times working pressure, test pressure 1.5 times design pressure.

ISO 15649: Prefabricated piping must undergo 100% radiographic testing (RT) or ultrasonic testing (UT), Class II qualified.

Pressure testing: Hydrostatic testing holding time ≥ 10 minutes; pneumatic testing must be conducted in sections (each section ≤ 50m).

Cleanliness: Austenitic stainless steel piping must undergo pickling and passivation; chloride ion content ≤ 25ppm (HG/T 20584).

Considerations for selecting precast pipe fittings

When selecting prefabricated pipe fittings, the following factors need to be considered:

Material: Choose an appropriate material based on the application scenario, such as steel, cast iron, or plastic.

Specifications: Determine the pipe diameter, wall thickness, and other specifications according to project requirements.

Quality: Select reliable prefabricated pipes that meet relevant standards to ensure project quality and safety.

Price: While meeting performance and quality requirements, rationally select prefabricated pipes with reasonable prices to control project costs.

Importance of drawings

Precast pipe fitting design is a core component of precast pipeline construction, and its importance cannot be overlooked.

Precast pipe fitting drawings provide detailed dimensions, material specifications, and connection details, ensuring that fittings are manufactured strictly according to design requirements in the prefabrication plant, reducing on-site modifications and errors.

Standardized drawings also unify design standards across different projects or fittings, improving overall consistency.

With precast pipe fitting drawings, fittings can be processed in parallel in the factory, shortening on-site installation time and accelerating construction progress. Clear installation sequences and interface information on the drawings help reduce on-site welding and commissioning work, minimizing human error and thus improving installation accuracy and project quality.

Precise drawings support accurate calculation of material usage, avoiding waste and optimizing procurement plans. Prefabrication reduces on-site labor and equipment requirements, lowering labor and management costs.

Simultaneously, drawings facilitate quantity surveying and budget control, enhancing project economics.

Drawings include safety specifications (such as stress analysis and corrosion protection requirements), guiding pipe rack design and installation, reducing construction risks.

Standardized design simplifies quality inspection processes, ensuring compliance with specifications and improving project reliability. Furthermore, drawings serve as a basis for construction, facilitating process traceability and subsequent maintenance management.

Applications of precast piping

Precast pipe fittings have wide applications in the industrial sector. In fields such as petrochemicals, natural gas transportation, and water treatment, precast pipe fittings are widely used in various pipeline systems.

They can withstand harsh environments such as high pressure and high temperature, ensuring the normal operation of the pipeline system.

Summary

Precast pipe fittings are an efficient, convenient, and safe method of pipe fabrication. They not only improve construction efficiency and reduce costs, but also ensure pipeline quality and safety.

In the future, with continuous technological advancements and expanding application areas, precast pipe fittings will be used and promoted in even more fields.

Metleader provides all the necessary pipe fittings needed for the precast pipe manufacturing process, including elbows, flanges, steel pipes, pipe clamps, and pipe caps; their quality meets international standards, and their prices are more competitive, with applications in over 80 countries.

We are committed to providing our customers with the highest quality service and assurance!