Beginner’s Guide: Basic Knowledge of Stainless Steel Elbows

Table of contents

- Features of Stainless Steel Elbows

- ASME B16.9 Specifications of Stainless Steel Elbows

- Material of Stainless Steel Elbows

- Manufacturing Process of Elbows

- Classification of Elbows by Radius of Curvature

- Classification of Elbows by Angle

- Dimensional Tolerances of Welded Butt Elbows

- Advantages of Stainless Steel Welded Butt Elbows

- Applications of Welded Butt Elbows

- Summary

Features of Stainless Steel Elbows

Stainless steel elbows possess exceptional characteristics, making them widely used in industrial construction, particularly in the oil and gas, chemical, construction, pharmaceutical, and food industries.

Stainless steel elbows feature excellent corrosion resistance, high strength and superior mechanical properties, high and low temperature resistance, good weldability and machinability, aesthetic appeal and ease of maintenance, and wear resistance.

Metleader offers a wide range of styles and sizes of stainless steel elbows, from 1/2 inch to 80 inches, with wall thicknesses covering SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, and XXS, conforming to ASME B16.9 standards.

To learn more about Metleader stainless steel elbows, please follow us on YouTube and LinkedIn.

ASME B16.9 Specifications of Stainless Steel Elbows

| Size Range | 1/2″- 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

Material of Stainless Steel Elbows

Stainless steel elbows are commonly made of 304, 316, and 201 stainless steel. 304 stainless steel is a general-purpose stainless steel material containing more than 18% chromium and more than 8% nickel.

201 stainless steel adds molybdenum to 304 stainless steel, significantly improving its corrosion resistance, especially in marine environments and chloride-containing media. 201 stainless steel contains manganese and is relatively inexpensive.

ASTM A403 Chemical Composition of Elbows

| Element | Grade WP304 / 304L | Grade WP316 / 316L | Grade WP321 | Grade WP347 / 348 |

| C | 304: ≤ 0.08 304L: ≤ 0.030 | 316: ≤ 0.08 316L: ≤ 0.030 | ≤ 0.08 | ≤ 0.08 |

| Mn | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| P | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| S | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Si | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 | ≤ 1.00 |

| Cr | 18.0 – 20.0 | 16.0 – 18.0 | 17.0 – 20.0 | 17.0 – 20.0 |

| Ni | 8.0 – 11.0 | 10.0 – 14.0 | 9.0 – 12.0 | 9.0 – 13.0 |

| Mo | – | 2.00 – 3.00 | – | – |

| Ti | – | – | ≥ 5×C, ≤ 0.70 | – |

| Cb+Ta | – | – | – | ≥ 10×C, ≤ 1.10 (Cb only for 348) |

| N | – | – | ≤ 0.10 | – |

ASTM A403 Mechanical Properties of Elbows

| Property | Grade WP304 / 304L / 321 / 347 | Grade WP316 / 316L | Grade WP S31803/S32205 |

| T.S min (MPa) | 515 | 515 | 620 |

| T.S (0.2% offset), min (MPa) | 205 | 205 | 450 |

| EL (%) | 35 | 35 | 25 |

Manufacturing Process of Elbows

Seamless: Seamless stainless steel elbows are made by connecting stainless steel sheets or pipes into a single unit through molding or welding, without any noticeable seams.

This process offers high production efficiency and product quality, making it widely used in industrial production.

Seamed: Seamed elbows are made from stainless steel sheets or strips through rolling and welding. They have lower manufacturing costs and shorter processing cycles, making them suitable for general industrial or low-pressure conveying systems.

Although the weld seam is a relatively weak point, improvements in welding technology and testing methods have enabled seamed elbows to be used reliably in many applications.

Classification of Elbows by Radius of Curvature

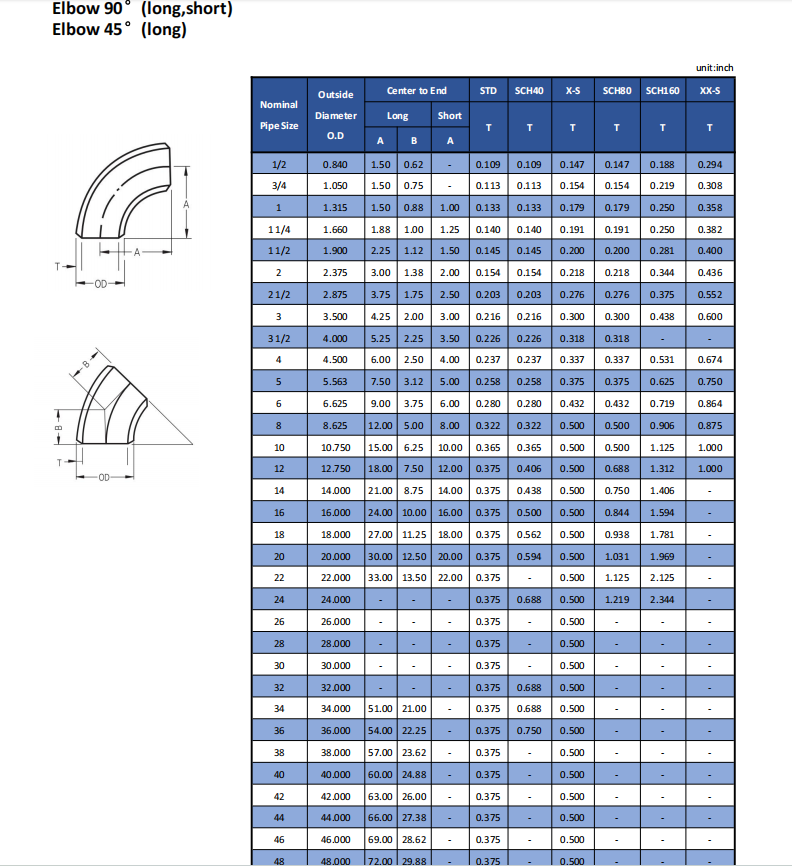

Elbows can be classified into two types based on their radius of curvature: long-radius elbows and short-radius elbows.

A long-radius elbow is defined as having a radius of curvature equal to 1.5 times the outer diameter of the pipe, i.e., R = 1.5D.

A short-radius elbow, on the other hand, has a radius of curvature equal to the outer diameter of the pipe, i.e., R = 1.0D. Here, D represents the elbow diameter, and R represents the radius of curvature.

Classification of Elbows by Angle

Elbows can be classified by angle into 45-degree, 60-degree, 90-degree, 120-degree, and 180-degree elbows; among them, 45-degree, 90-degree, and 180-degree elbows are the most common.

45-degree Elbow

Changing the fluid direction by 45 degrees results in a smoother turn compared to a 90-degree bend, and is typically a long-radius type. It produces less turbulence and pressure loss compared to a 90-degree bend.

60-degree Elbow

A 60-degree elbow is a connector in a piping system used to change the direction of fluid flow by 60°. 60-degree elbows are non-standard angle pipe fittings.

90-degree Elbow

Changing the fluid direction by 90 degrees to form a right angle is the most common type of elbow.

120-degree Elbow

A 120-degree elbow is a pipe fitting used in piping systems to change the direction of fluid flow. Its bending angle is 120 degrees, and it is a custom-made model for engineering projects.

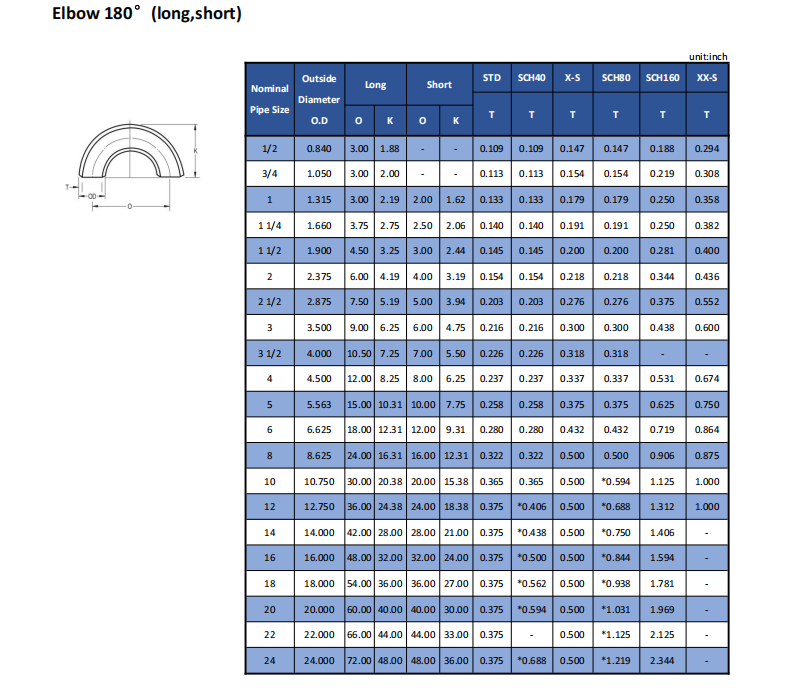

180-degree Elbow

Reversing the fluid direction completely by 180 degrees is commonly used in heating coils, process loops, or piping designs with limited space.

Dimensional Tolerances of Welded Butt Elbows

Advantages of Stainless Steel Welded Butt Elbows

Strong Connection and Excellent Sealing: Butt-welded connections allow for integrated connection of pipes and elbows, reducing leakage risks and making them suitable for high-pressure and high-temperature environments.

Strong Corrosion Resistance: Made of 304 or 316 stainless steel, offering excellent corrosion resistance and adaptability to various corrosive media.

Long Service Life: High mechanical strength, wear-resistant, and heat-resistant, suitable for long-term operation and reduced maintenance costs.

Low Fluid Resistance: The long radius design facilitates smooth fluid flow, reducing pressure loss and energy consumption.

Aesthetically Pleasing and Hygienic: Both inner and outer surfaces can be polished, making them particularly suitable for industries with high hygiene requirements, such as food and pharmaceuticals.

Applications of Welded Butt Elbows

In terms of pipeline system pressure, it is suitable for medium and high pressure pipeline systems.

In terms of transported media, it is suitable for a variety of media, such as steam, water, and oil.

In terms of industry applications, it is widely used in the petroleum, chemical, and power industries.

Summary

This article has introduced the classification, specifications, manufacturing processes, and characteristics of stainless steel elbows, which can help us better select suitable elbow fittings.

Stainless steel elbows play a crucial role in piping systems, and understanding this knowledge can provide advice and reference for future procurement.

Metleader, as one of China’s largest elbow manufacturers and suppliers, maintains a large inventory year-round, supports customization, and offers fast delivery. Global partners are welcome to send inquiries.