Detailed explanation of flange knowledge: Duplex stainless steel flanges vs. stainless steel flanges

Table of contents

- What are duplex stainless steel flanges?

- What are stainless steel flanges?

- Basic knowledge of duplex stainless steel flanges

- Basic knowledge of stainless steel flanges

- Duplex stainless steel flanges vs. stainless steel flanges

- Export countries for flanges

- Why choose Metleader?

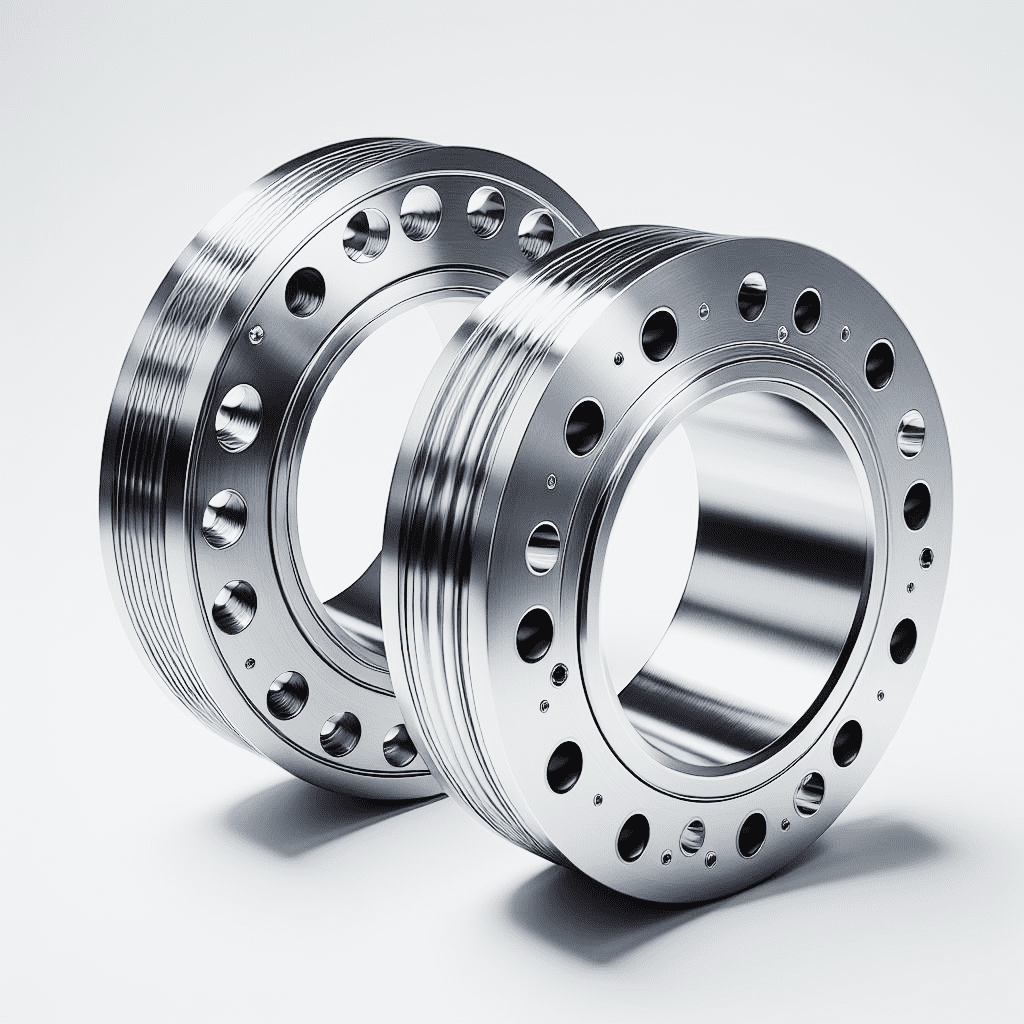

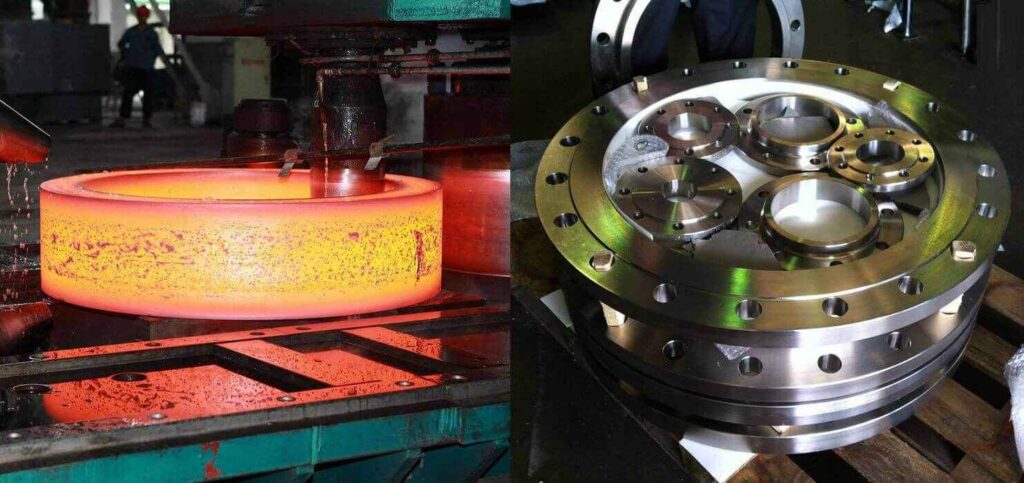

What are duplex stainless steel flanges?

Duplex stainless steel flanges are flanges manufactured from duplex stainless steel materials. These flanges combine the excellent properties of both austenitic and ferritic stainless steels, and perform exceptionally well, especially in extremely corrosive environments.

What are stainless steel flanges?

Stainless steel flanges are common pipe connectors widely used in various industrial fields, including petroleum, chemical, food processing, and pharmaceuticals. The design and structure of stainless steel flanges can be adjusted to meet the requirements of different piping systems.

Basic knowledge of duplex stainless steel flanges

To understand the basics of duplex stainless steel flanges, we need to first understand their standards, types, characteristics, and applications.

These will be discussed in detail below:

Standards for duplex stainless steel flanges

| Standard | Flange Types (English) |

|---|---|

| ASME/ANSI B16.5 | Weld Neck, Slip-On, Blind, High-Hub Blind, Socket Weld, Lap Joint, Threaded, Ring Type Joint |

| ASME/ANSI B16.47 | Weld Neck, Blind [Series A & B] |

| ASME/ANSI B16.36 | Weld Neck, Slip-On, Threaded |

| BS 1560 BOSS | Weld Neck, Socket Weld, Slip-On, Blind, Threaded Boss, Lap Joint |

| BS10 | Weld Neck, Plate Slip-On, Threaded Boss, Slip-On Boss, Blind |

Types of duplex stainless steel flanges

WN type flanges are a common type of flange. They have high strength and good sealing performance, making them suitable for high-pressure, high-temperature, and low-temperature applications.

SO type flanges are suitable for low-pressure, non-corrosive media applications. Their welding method is relatively simple, and the cost is lower.

PL type flanges are one of the simplest types of flanges. They are welded directly to the pipe without a neck. PL type flanges are suitable for low-pressure, normal temperature applications and have a relatively low cost.

Characteristics of duplex stainless steel flanges

- A balance of high strength and good toughness

- Excellent corrosion resistance

- Good fatigue resistance

- Low coefficient of thermal expansion

Applications of duplex stainless steel flanges

- Petrochemical industry

- Offshore engineering sector

- Power industry

- Food and beverage industry

- Construction industry

Basic knowledge of stainless steel flanges

To understand the basics of stainless steel flanges, we need to first understand their standards, types, characteristics, and applications. We will discuss each of these below:

Standards for stainless steel flanges

American Standards: ANSI B16.5, including Class 150, 300, 600, 900, 1500 (TH, LJ, SW)

Japanese Standards: JIS 5K, 10K, 16K, 20K (PL, SO, BL)

German Standards: DIN 2527, 2543, 2545 series, etc. (PL, SO, WN, BL, TH)

Italian Standards: UNI 2276, 2277 series, etc. (PL, SO, WN, BL, TH)

British Standards: BS 4504, 4506

Classification of stainless steel flanges

RF flange: The flange face has a raised sealing surface, and sealing is achieved by compressing a gasket. This is the most common type.

FF flange: The end face is flat and requires the use of a full-face gasket. It is mostly used for low-pressure or non-metallic pipelines.

RTJ flange: The end face has an annular groove into which a metal ring gasket is inserted. It provides strong sealing and is suitable for high-pressure and high-temperature conditions.

MFM flange: One side is convex and the other is concave. When used together, it prevents gasket misalignment and provides more reliable sealing.

Characteristics of stainless steel flanges

- Excellent corrosion resistance

- High strength and durability

- Wide temperature range adaptability

Applications of stainless steel flanges

- Water piping systems

- Drainage systems

- Oil and gas pipeline systems

- Chemical pipeline systems

- Pharmaceutical pipeline systems

- Offshore pipeline systems

Installation of stainless steel flanges

- Preparation: Check that the specifications of the flanges, gaskets, and bolts match and are undamaged; clean the pipe ends and flange sealing surfaces to ensure they are free of impurities.

- Positioning: Align the two pipes to be connected on the same axis, and place the flanges onto the pipes so that the flange sealing surfaces face each other. Ensure the flange holes are aligned.

- Placing the gasket: Place a suitable gasket on one of the flange sealing surfaces, ensuring the gasket is correctly positioned, flat, and free of wrinkles or displacement.

- Connecting the flanges: Bring the two flanges together, insert the bolts. The bolts should be inserted from the same side of the flange to ensure they can pass freely through the bolt holes.

- Tightening the bolts: Use a wrench to tighten the bolts evenly in a diagonal pattern, gradually reaching the specified tightening torque in 2-3 steps to prevent uneven stress on the flange and potential leaks.

- Inspection: After installation, check that the flange connection is tight and the gasket is properly seated, ensuring there are no potential leaks.

Duplex stainless steel flanges vs. stainless steel flanges

| Feature | Duplex Stainless Steel Flanges | Austenitic Stainless Steel Flanges |

| Primary Alloy | 22-25% Cr, 3-7% Ni, 0.1-0.3% N, Mo | 16-26% Cr, 6-22% Ni |

| Microstructure | ~50% Ferrite + ~50% Austenite | 100% Austenite |

| Strength | Yield: 450-550 MPa | Yield: 205-310 MPa |

| Parameter | Duplex Stainless Steel Flanges | Austenitic Stainless Steel Flanges |

| Corrosion Resistance | Superior pitting/crevice corrosion resistance | Good general corrosion resistance |

| Temperature Limits | Max 300°C (risk of embrittlement) | Up to 800°C (304) |

| Cost Factor | Higher (alloy content) | Lower (standard grades) |

| Typical Grades | UNS S31803, S32205, S32750 | 304/L, 316/L, 321 |

Export countries for flanges

| Continent | Countries/Regions (English) |

|---|---|

| Asia | Saudi Arabia, Iran, Iraq, United Arab Emirates (UAE), Qatar, Bahrain, Oman, Kuwait, Turkey, Yemen, Syria, Jordan, Cyprus, India, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar, Taiwan (China), Cambodia |

| Africa | Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, Republic of the Congo, Gabon |

| North America | United States, Canada, Mexico, Panama, Costa Rica, Puerto Rico (U.S. territory), Trinidad and Tobago, Jamaica, Bahamas |

| South America | Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay |

| Europe | Russia, Norway, Germany, France, Italy, United Kingdom (UK), Spain, Ukraine, Netherlands, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta |

Why choose Metleader?

Metleader is a renowned Chinese supplier, stockist, distributor, manufacturer, and exporter of duplex stainless steel flanges.

We provide our customers with high-quality flanges, all products meet international standards and can be customized according to customer requirements.

Having gained recognition and support from customers in over 80 countries, we provide complete solutions for our clients’ industrial projects.

Please feel free to email us to receive our latest product catalog and price list.