ASTM vS ASME Standards: How to Choose Carbon Steel Pipe Fittings

Contents

- Introduction

- Carbon Steel Pipe Fitting Types and Specifications

- ASTM Standards

- ASME Standards

- ASTM VS ASME

- How to Choose the Right Carbon Steel Pipe Fittings

- FAQs

- Summary

Introduction

Carbon steel pipe fittings are very common in industrial environments and are also an important part of industrial construction. Choosing high-quality carbon steel pipe fittings is the basis for ensuring the smooth delivery of the project;

Once poor quality and unqualified products are selected, the project is likely to lose millions of dollars;

Therefore, high-quality carbon steel pipe fittings are very important.

In addition, we also need to understand the parameter differences between ASTM and ASME Standards to ensure the smooth delivery of the project.

Let’s take a detailed look at how to choose the right carbon steel pipe fittings through this article.

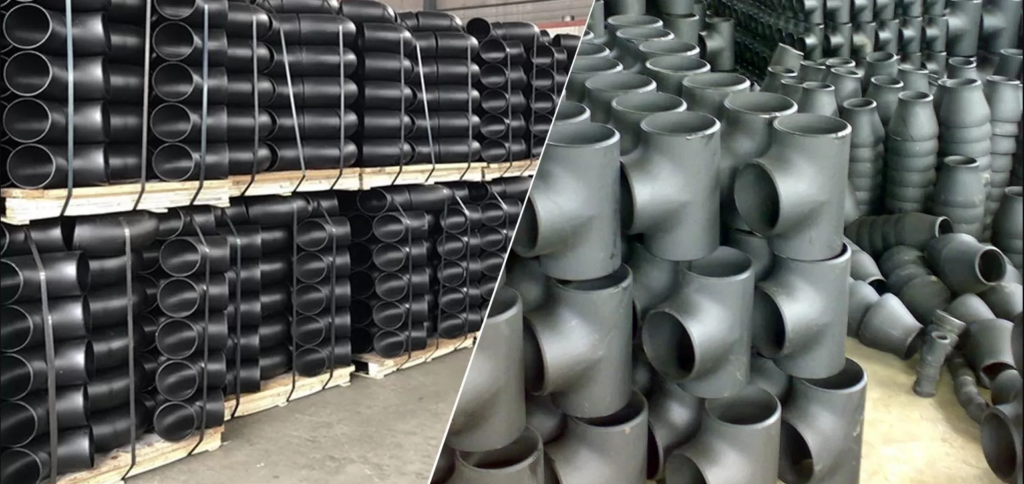

Carbon Steel Pipe Fitting Types and Specifications

Carbon steel pipe fittings connect, control, and redirect fluids in pipelines.

Their performance depends on three factors:

- Material Grade (e.g., ASTM A234 WPB, A105).

- Pressure-Temperature Ratings (PSI/Bar, °C/°F).

- Manufacturing Standards (ASTM vs. ASME).

Common Types of Fittings:

- Elbows (90°, 45°).

- Tees (Equal, Reducing).

- Flanges (Slip-On, Weld Neck).

- Couplings (Half, Full).

ASTM Standards

ASTM A234 WPB: Standard Specification for Carbon Steel Pipe Fittings for Moderate-Temperature Service.

ASTM A105: Forged Carbon Steel Components for Top-Temperature and High-Temperature Service.

ASTM Advantages

Cost-effective: 20-30% cheaper than ASME fittings.

Widely applicable: Widely used in construction, HVAC and general manufacturing.

Simplified testing: Only basic chemical and mechanical tests are required.

ASTM Limitations

Pressure Limits: Up to 3000 PSI (206 Bar).

Temperature Range: -29°C to 425°C (-20°F to 797°F).

Not for use in: Nuclear power plants or ultra-high pressure systems.

ASME Standards

ASME B16.9: Factory-made forged steel butt-weld fittings.

ASME B16.11: Forged steel fittings, socket-weld and threaded fittings.

ASME B16.5: Pipe flanges and flanged fittings.

ASME Advantages

Higher pressure capability: up to 6000 PSI (413 Bar).

Wider temperature range: -196°C to 650°C (-320°F to 1202°F).

Strict quality control: mandatory non-destructive testing (NDT), such as X-ray and ultrasonic testing.

ASME Limitations

Higher cost: 40-50% more expensive than ASTM.

Longer lead time: 8-12 weeks for custom designs.

ASTM VS ASME

| Parameter | ASTM | ASME |

| Pressure Rating | ≤ 3000 PSI | ≤ 6000 PSI |

| Temperature Range | -29°C to 425°C | -196°C to 650°C |

| Testing | Basic chemical/mechanical | NDT (X-ray, ultrasonic) |

| Certification | ISO 9001 | ASME “U” Stamp |

| Cost | 100−100−500 per fitting | 200−200−1000 per fitting |

| Best For | General industrial use | Oil & gas, nuclear, aerospace |

How to Choose the Right Carbon Steel Pipe Fittings

Define System Requirements

Measure operating pressure, temperature, and fluid type (e.g., corrosive chemicals).

Match Industry Regulations

Oil & gas: API 6A (ASME preferred).

Construction: ASTM A234 WPB.

Evaluate Budget vs. Risk Tolerance

Verify Supplier Credentials

ASTM: Check ISO 9001 certification.

ASME: Demand “U” Stamp authorization and NDT reports.

FAQs

Q1: Can I mix ASTM and ASME fittings in one system?

A: Technically possible but not recommended. Mismatched standards risk leaks and compliance issues.

Q2: Which standard is better for cryogenic applications?

A: ASME B16.34 supports temperatures as low as -196°C.

Q3: How do I confirm a supplier meets ASME standards?

A: Request their ASME“U”Stamp certificate and third-party NDT reports.

Summary

ASTM Standards and ASME Standards have different assessment standards in different environments. Although they have similarities, for the safety of the project, it is still necessary to choose carbon steel pipe fittings that meet the standards;

Metleader can produce carbon steel pipe fittings that meet ASTM Standards and ASME Standards, and has experience in cooperation with Fortune 500 companies, and can provide customers with complete solutions.

I hope this article can help you optimize your project!