A Comprehensive Guide to ASME B16.9 Stainless Steel Welded Elbows: Dimensions, Standards, and Applications

Contents

- Preface

- What is a Butt-Welded Elbow?

- What is the ASME B16.9 Standard?

- Classification of Elbows

- Standards for Stainless Steel Butt-Welded Elbows

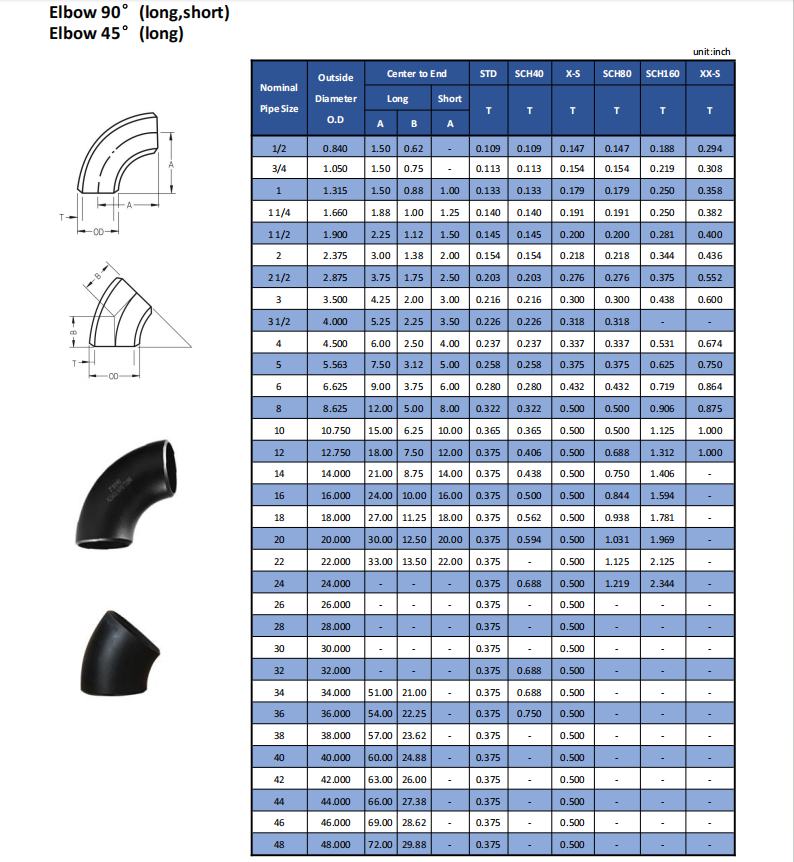

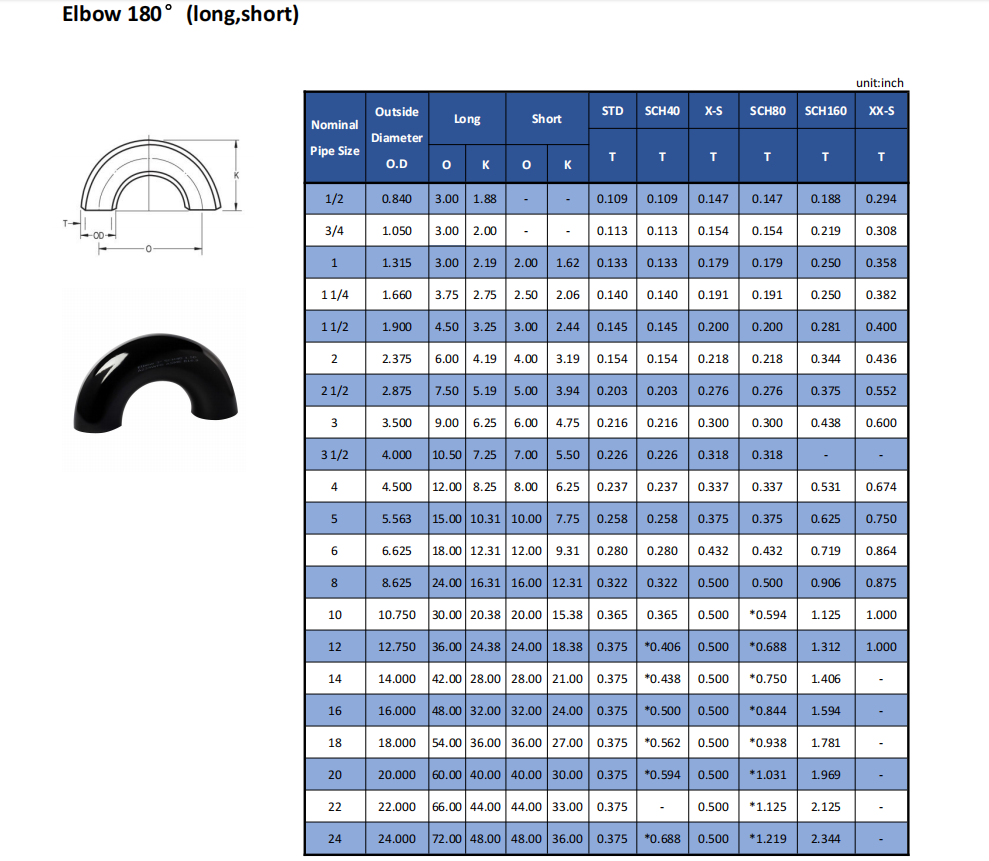

- Size Table for Butt-Welded Elbows

- Butt Welding vs. Socket Welding

- Applications of Butt-Welded Elbows

- Selection and Installation of Butt-Welded Elbows

- FAQ

- Summary

Preface

AMSE B16.9 standard weld neck elbows are frequently used in the oil and gas, power, pharmaceutical, chemical, and construction industries.

Understanding the characteristics of this type of elbow can help us better select the appropriate one.

This article provides a comprehensive overview of the dimensions, standards, and applications of ASME B16.9 stainless steel weld neck elbows, as well as potential problems encountered in practical applications. We hope this will be helpful.

If you would like to learn more about elbow manufacturing through videos and information, please follow us on YouTube and LinkedIn.

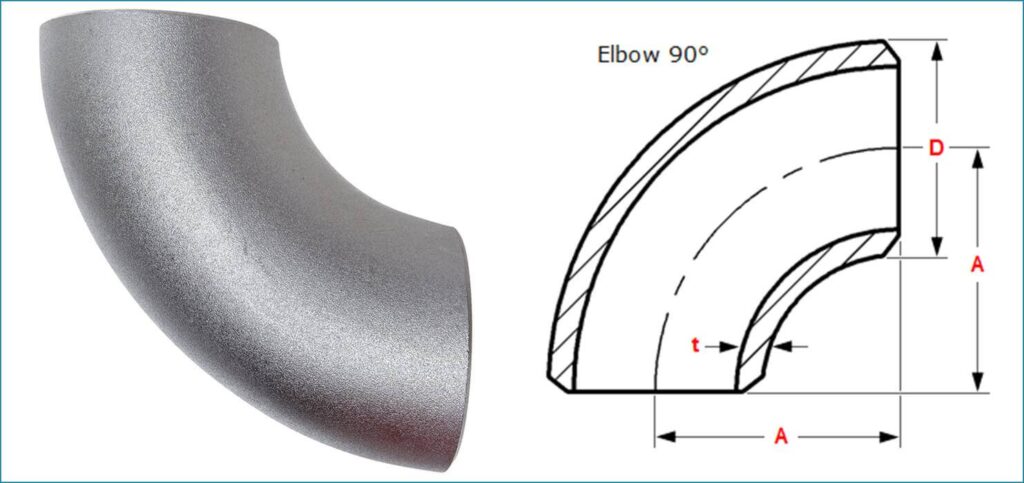

What is a Butt-Welded Elbow?

A butt-welded elbow is a type of pipe fitting that connects to a pipeline via butt welding, primarily used to change the direction of fluid transport.

“Butt welding” refers to the process of aligning and welding the elbow to the pipe end to create a permanent seal.

What is the ASME B16.9 Standard?

ASME B16.9 is a general standard for pipe elbows. It details the requirements for elbow dimensions, materials, pressure ratings, and manufacturing and inspection procedures.

ASME B16.9 covers elbows of different angles, such as 45-degree and 90-degree elbows. It also provides clear specifications for elbow radii, wall thicknesses, and connection methods.

ASME B16.9 provides a unified standard for the design and manufacture of piping systems.

Classification of Elbows

Elbows can be classified by bending radius into long-radius elbows and short-radius elbows.

By bending angle, elbows can be classified into 45-degree elbows, 90-degree elbows, and 180-degree elbows.

By manufacturing method, elbows can be classified into seamless elbows and straight-seam elbows.

By material, elbows can be classified into carbon steel elbows, stainless steel elbows, and alloy steel elbows.

Standards for Stainless Steel Butt-Welded Elbows

The ASME B16.9 standard clearly specifies the dimensional tolerances for stainless steel weld neck elbows, including length, wall thickness, inner diameter, outer diameter, and other aspects. Dimensional deviations must be within the tolerance range specified in the standard.

| Nominal Size | All Fittings | 45°&90° Elbows & Tees, Crosses | 3D Radius Elbows | 180 ° elbows | ||||

| DN | NPS | OD 3) 4) | ID 3) | A B C M | A B | O | K | U |

| 15-65 | 1/2 -21/2 | +1.6 -0.8 | ± 0.8 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 |

| 80-90 | 3-31/2 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 |

| 100 | 4 | ± 1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 |

| 125-200 | 5-8 | +2.4 -1.6 | ± 1.6 | ± 2 | ± 3 | ± 6 | ± 6 | ± 1 |

| 250-450 | 10-18 | +4.0 -3.2 | ± 3.2 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 |

| 500-600 | 20-24 | +6.4 -4.8 | ± 4.8 | ± 2 | ± 3 | ± 10 | ± 6 | ± 2 |

| 650-750 | 26-30 | +6.4 -4.8 | ± 4.8 | ± 3 | ± 6 | — | — | — |

| 800-1200 | 32-48 | +6.4 -4.8 | ± 4.8 | ± 5 | ± 6 | — | — | — |

Size Table for Butt-Welded Elbows

Butt Welding vs. Socket Welding

Butt welding connection

Principle: Two pipe fittings are joined and welded together to form an integrated connection;

Advantages: High connection strength and good sealing; Suitable for high-pressure and high-temperature environments; No risk of internal leakage, suitable for conveying hazardous media;

Disadvantages: Requires specialized welding equipment and techniques; The welding process may cause thermal deformation or welding defects; Difficult to disassemble, resulting in high maintenance costs.

Socket welding connection

Principle: The elbow is inserted into the end of the pipe and then welded.

Advantages: Simple operation, suitable for small-diameter pipes; weld quality is relatively easy to control.

Disadvantages: Prone to crevice corrosion; suitable for low-pressure and low-temperature environments; not suitable for conveying corrosive or high-velocity media.

Applications of Butt-Welded Elbows

Butt-welded elbows are widely used in various industries due to their excellent performance and broad applicability.

In the petrochemical industry, butt-welded elbows are extensively used in oil refining units, chemical equipment, and pipeline transportation.

In the natural gas transportation sector, butt-welded elbows are a key component for achieving long-distance, high-flow-rate natural gas transportation.

Furthermore, butt-welded elbows play an irreplaceable role in urban construction, water treatment, and heating systems.

Selection and Installation of Butt-Welded Elbows

The selection and installation of welded elbows are also very important in different industrial environments:

Selection of Butt-Welded Elbows

For transporting crude oil and natural gas, corrosion-resistant alloy steel elbows with a wall thickness ≥8mm should be selected. For high-temperature steam pipelines, P91 material is preferred, and the bending radius should be at least 1.5 times the pipe diameter.

Carbon steel should be avoided for acidic media to prevent hydrogen embrittlement.

Installation of Butt-Welded Elbows

During installation, determine the pipeline route according to design requirements. Perform a preliminary butt-welded elbow connection to the pipeline, ensuring that their centerlines coincide. The joint should be smooth with a uniform gap, generally controlled at 2-3mm.

Use appropriate welding techniques for spot welding to fix the relative position of the elbow and pipeline. During spot welding, ensure the weld points are evenly distributed to prevent welding deformation.

FAQ

Q: What problems are prone to occur during the welding of stainless steel welded elbows?

A: Potential problems during welding include weld cracking, porosity, and incomplete penetration. These problems are usually related to improper welding processes, material selection, or operation.

Q: What problems may occur with stainless steel welded elbows during use?

A: After long-term use, elbows may experience corrosion, weld leakage, or deformation. Regular inspection and maintenance can extend the service life of the elbows.

Q: What are the production standards for stainless steel welded elbows?

A: Common production standards include GB/T12459, ANSI/ASME B16.9, and EN10253.

Q: Can stainless steel welded elbows be connected to pipes of other materials?

A: Yes, but material compatibility must be considered. For example, direct connection between stainless steel and carbon steel may cause electrochemical corrosion due to potential difference; it is recommended to use insulating joints or transition fittings.

Summary

Welded elbows are crucial connecting components in piping systems, and their performance and quality directly affect the safety and reliability of the entire system.

Therefore, careful selection and installation of welded elbows are essential to ensure the normal operation and long-term stability of the piping system.

Metleader, as one of China’s largest elbow and pipe fitting manufacturers, has provided high-quality elbows and fittings to global customers for many consecutive years, gaining international recognition.

Furthermore, we have extensive experience in various industrial project construction and can provide complete elbow solutions. We welcome global partners to seek cooperation.