Comprehensive understanding of steel pipes: materials, types and applications

Contents

- Introduction

- Classification of Steel Pipes

- Characteristics of Steel Pipes

- Square Welded Pipes

- Rectangular Welded Pipes

- Spiral Welded Pipes

- Hot-Dip Galvanized Welded Pipes

- General Welded Pipes

- Summary

Introduction

Steel pipes are an essential element in our lives. Their unique properties and wide range of applications have made them an integral part of the industrial landscape.

Below, we’ll delve into the details of steel pipes and provide you with a comprehensive understanding.

Classification of Steel Pipes

There are many ways to classify steel pipes, and we can classify them from different perspectives. The following are some common classification methods:

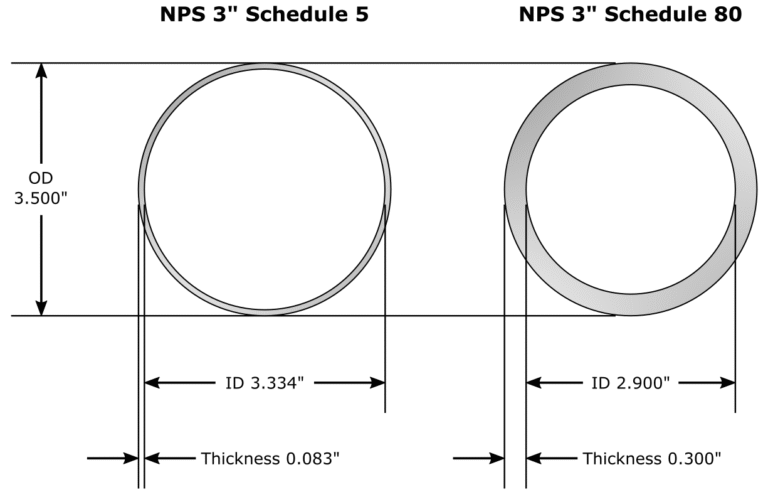

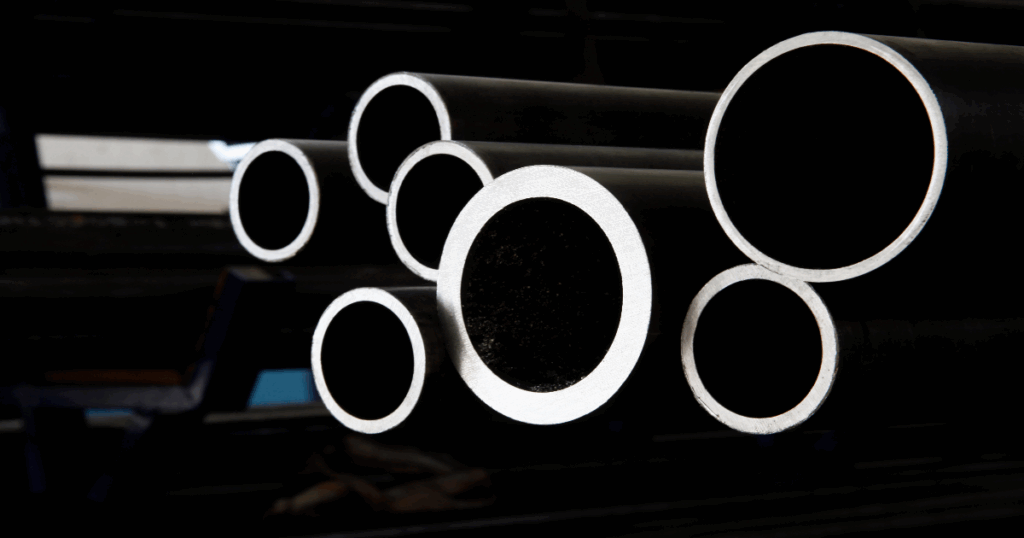

According to the cross-sectional shape, steel pipes can be divided into various types such as round, square, rectangular and special-shaped.

According to the material, steel pipes include carbon structural steel pipes, low alloy structural steel pipes, alloy steel pipes, composite steel pipes, stainless steel and duplex steel, etc.

According to the purpose, steel pipes can be used in many fields such as pipelines, engineering structures, thermal equipment, petrochemical industry, machinery manufacturing, geological drilling and high-pressure equipment.

In addition, according to different production processes, steel pipes can be divided into two categories: seamless steel pipes and welded steel pipes.

Characteristics of Steel Pipes

Round steel pipe: Its cross-section is circular, offering excellent plasticity and toughness, and is widely used for conveying fluids and supporting structures.

Square and rectangular steel pipe: Its cross-section is square or rectangular, offering strong load-bearing capacity and commonly used in building structures and machinery manufacturing.

Special-shaped steel pipe: Its cross-section is non-circular and can be customized to meet specific requirements, making it suitable for specialized applications.

Carbon structural steel pipe: Made from carbon structural steel, it is affordable and suitable for general engineering structures.

Low-alloy structural steel pipe: Made from carbon structural steel with a small amount of alloying elements, it offers higher strength and toughness.

Alloy steel pipe: Its material contains multiple alloying elements, resulting in excellent performance and commonly used in high-pressure equipment, petrochemicals, and other fields.

Composite steel pipe, stainless steel, and duplex steel pipe: These pipes offer excellent corrosion and wear resistance, making them suitable for use in harsh environments.

Square Welded Pipes

The zinc layer is formed through an electroplating process and is separated from the steel pipe substrate to present an independent layered state.

Classification of Square Welded Pipes

According to the welding process, they can be divided into arc welded pipes, high-frequency or low-frequency resistance welded pipes, gas welded pipes, furnace welded pipes, etc.

According to their welding form, they can be divided into straight seam welded pipes and spiral welded pipes.

Applications of Square Welded Pipes

Galvanized pipes have a wide range of uses.

In addition to being used as line pipes for conveying general pressure liquids such as water, gas, and oil, they are also commonly used in the petroleum industry, especially in oil well pipes and oil pipelines in offshore oil fields.

Rectangular Welded Pipes

Square welded pipe is a steel pipe with equal side lengths, which is rolled by processing strip steel.

Classification of Rectangular Welded Pipes

According to the material, square tubes can be divided into stainless steel, duplex steel, carbon steel, low alloy steel and alloy steel.

In terms of process, square tubes can be divided into arc welded tubes, electric resistance welded tubes, gas welded tubes and furnace welded tubes.

Applications of Rectangular Welded Pipes

In construction projects, square tubes are often used as structural supports, forming the framework of houses.

They also play an indispensable role in machinery manufacturing and steel construction.

Furthermore, square tubes are frequently used in shipbuilding, solar power generation racks, steel structure engineering, and power engineering projects.

Spiral Welded Pipes

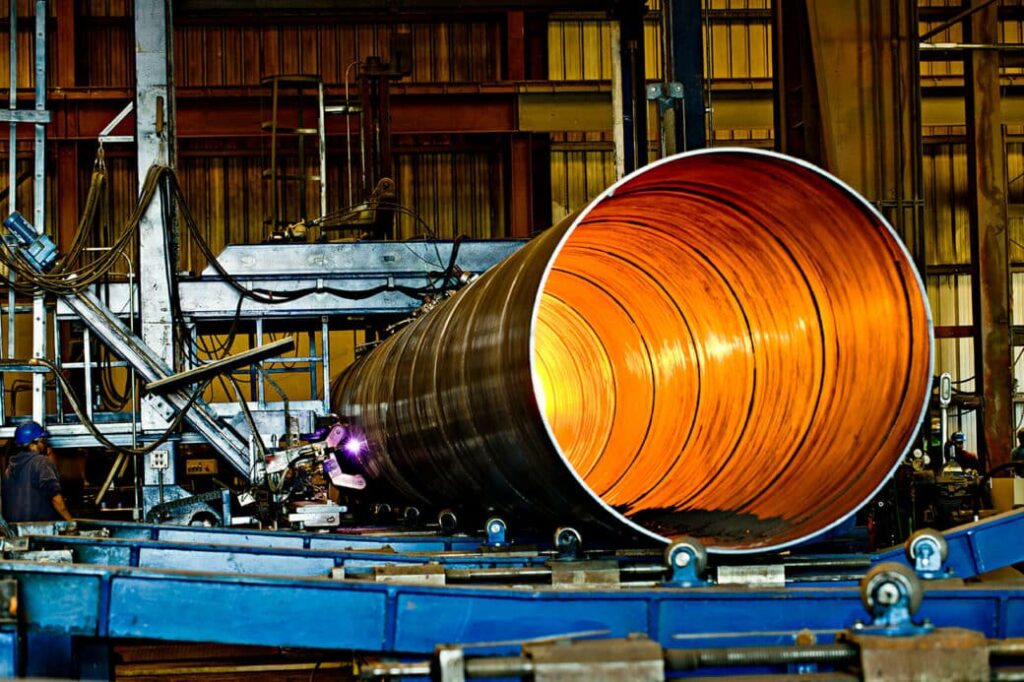

Spiral steel pipes are made of strip steel coils, extruded at room temperature, and welded using submerged arc welding technology to form spiral seam steel pipes.

Classification of Spiral Welded Pipes

According to the material, it can be divided into stainless steel, carbon steel, low alloy steel and alloy steel.

From the process point of view, it can be divided into two types: double-sided submerged fox welding and single-sided submerged fox welding.

Characteristics of Spiral Welded Pipes

Spiral welded pipes have a unique place in the field of welded pipes due to their unique properties.

Their corrosion resistance and strong plasticity enable them to work stably in a variety of environments.

Applications of Spiral Welded Pipes

Spiral welded pipes are widely used in various fields in China. In water supply projects, they are often used as water supply and drainage pipes.

They are also often used in the petrochemical, chemical, and power industries to transport gases such as coal gas, steam, and liquefied petroleum gas.

Hot-Dip Galvanized Welded Pipes

Hot-dip galvanized welded pipes are made by reacting molten metal with the iron matrix to form an alloy layer on the matrix, achieving a close bond between the matrix and the coating.

Classification of Hot-Dip Galvanized Welded Pipes

According to the welding process, it can be divided into arc welded pipe, high frequency or low frequency resistance welded pipe, gas welded pipe, furnace welded pipe, etc.

According to the welding form, straight seam welded pipe and spiral welded pipe are the two main types.

Characteristics of Hot-Dip Galvanized Welded Pipes

Hot-dip galvanized welded pipes are known for their uniform coating, strong adhesion, and excellent service life.

Applications of Hot-Dip Galvanized Welded Pipes

Hot-dip galvanized welded pipes are widely used in various fields, including construction, machinery, coal mining, chemical industry, power generation, railway vehicles, automobile industry, and even in the manufacture of roads, bridges, and containers, as well as sports facilities, agricultural machinery, petroleum machinery, and prospecting machinery.

General Welded Pipes

Generally, welded pipes are mainly used to transport low-pressure fluids. Their manufacturing materials include Q195A, Q215A, and Q235A steels.

Other soft steels that are easy to weld can also be used for manufacturing.

Classification of General Welded Pipes

By material: stainless steel, duplex steel, low-alloy steel, etc.

By shape: oval, triangular, L-shaped, octagonal, mushroom, etc.

By manufacturing standard: American standard, German standard, Japanese standard, Russian standard, ISO, etc.

By connection method: welding, clamp, threaded connection.

Characteristics of General Welded Pipes

The production process is relatively simple, the production efficiency is high and the cost is low, so it has developed rapidly.

Applications of General Welded Pipes

- Water supply projects

- Petrochemical industry

- Chemical industry

- Electric power industry

- Agricultural irrigation

- Urban construction

Summary

Steel pipes play a vital role in the industrial field. They are not only widely used in conveying fluids and powdered solids and exchanging heat energy, but are also an important raw material for manufacturing mechanical parts and containers.