Concentric Reducer Basics: Construction, Applications, and Selection Tips

Table of contents

- Introduction

- What is a concentric reducer?

- Structural characteristics of a concentric reducer

- Application scenarios for concentric reducers

- Functions of concentric reducers

- Technical specifications for applications

- Common materials for concentric reducers

- Specifications and models of concentric reducers

- Concentric reducers vs eccentric reducers

- How to choose a reducer

- Summary

Introduction

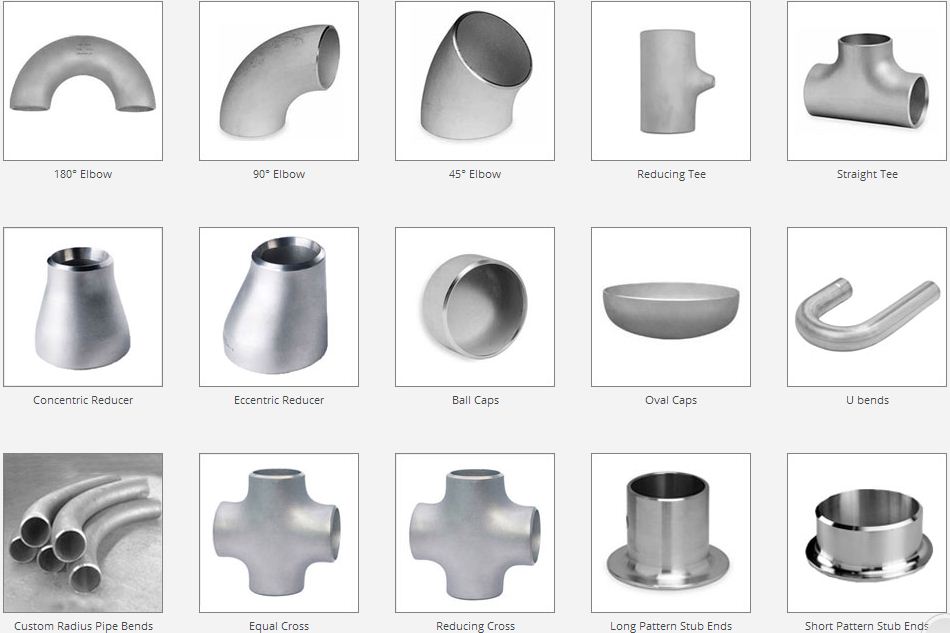

Anyone familiar with steel pipe fittings knows that reducers come in two types: concentric and eccentric. However, their specific applications may not be clear.

Next, we’ll delve deeper into the application scenarios of concentric reducers.

To learn more about reducers, follow us on YouTube and LinkedIn.

What is a concentric reducer?

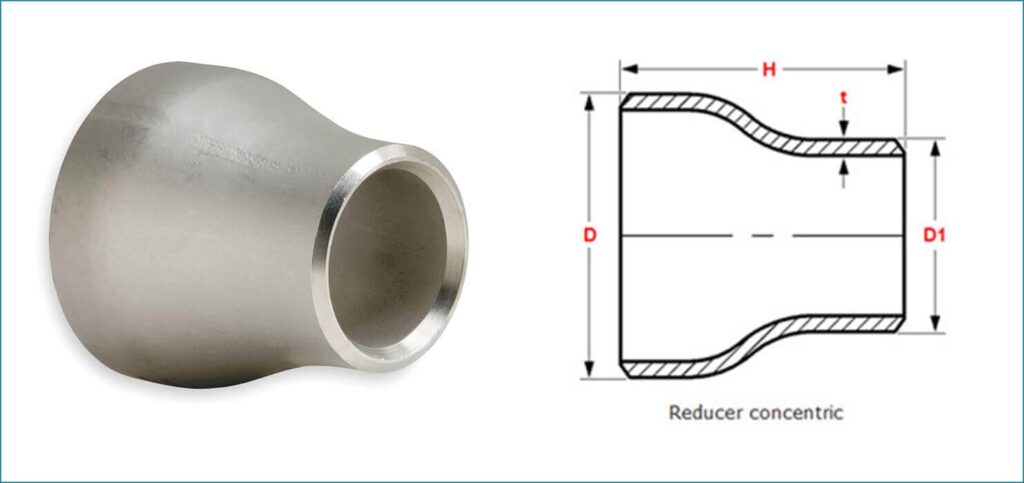

Concentric reducers, also known as reducing joints and reducing clamps, are mainly used to connect two pipes with different diameters.

Structural characteristics of a concentric reducer

The concentric reducer has a unique design where the diameters at both ends are different, but the centerlines coincide, meaning they are “concentric.”

This design allows fluid in the piping system to flow smoothly through the area with varying diameters, reducing fluid resistance and pressure loss.

Application scenarios for concentric reducers

Concentric reducers are widely used in various piping systems, such as those in the chemical, petroleum, natural gas, and water treatment industries.

In addition, urban water supply and drainage systems also require a large number of concentric reducers to accommodate the connection needs of pipes of varying diameters.

Functions of concentric reducers

The functions of concentric reducers can be categorized as follows:

- Mixing or diverting fluids. Concentric reducers can mix or divert two fluids of different diameters to meet different process requirements.

- Regulating flow and pressure drop. By adjusting the diameter ratio of the two pipes, different flow rates and pressure drops can be distributed to meet process requirements.

- Ensuring smooth flow and steady flow. The geometric shape and structural design of concentric reducers prevent fluid blockage and flow stall, ensuring smooth flow and steady flow.

- Expanding the cross-sectional area of the flow channel. When connecting two pipes of different diameters, concentric reducers can expand the cross-sectional area of the flow channel, reducing pressure drop and fluid resistance.

Technical specifications for applications

During installation, the pipe axes at both ends must be strictly aligned, and welding or flange connections must comply with standards such as ASME B16.9.

In the chemical, water supply, and drainage industries, the selection of concentric reducers directly impacts system energy consumption and maintenance cycles.

Through systematic design and precise calculations, concentric reducers can effectively improve the reliability and cost-effectiveness of piping systems, making them indispensable functional components in industrial piping.

Common materials for concentric reducers

Carbon steel: Cost-effective and high pressure resistance.

Stainless steel: Corrosion-resistant, used in the food and chemical industries.

Alloy steel: Suitable for high-temperature and high-pressure environments, such as oil pipelines.

Specifications and models of concentric reducers

Size Range

- Nominal Diameter: DN15-DN1200;

Wall Thickness Grades

- According to the ASME B16.9 standard, these grades are classified as Sch5, Sch10, Sch40, Sch80, and Sch160. The larger the number, the thicker the wall thickness.

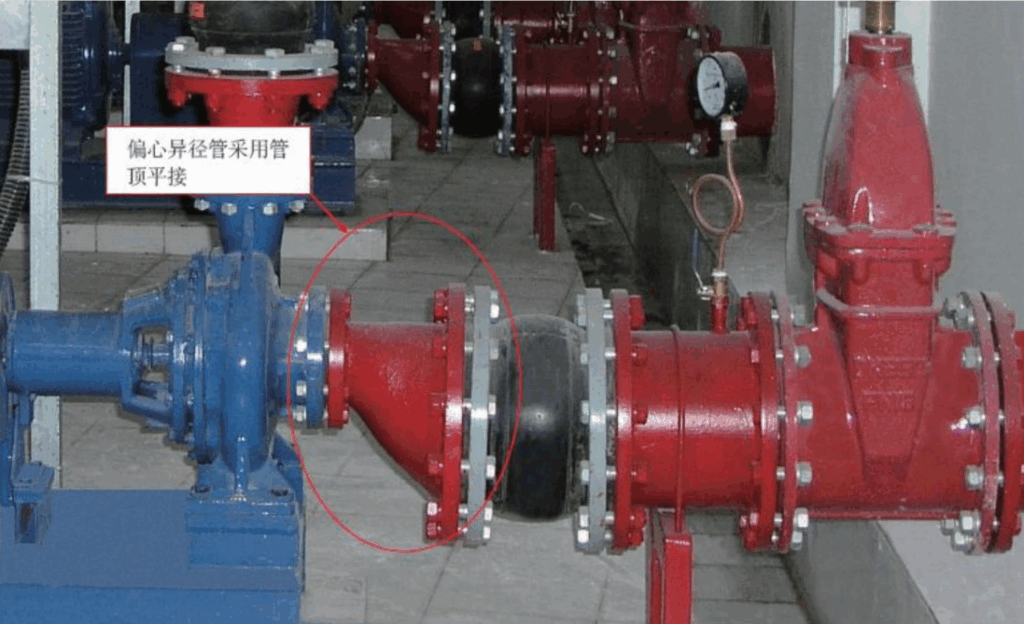

Concentric reducers vS eccentric reducers

| Feature | Concentric Reducer | Eccentric Reducer |

| Geometry | Symmetrical conical shape | Offset conical shape |

| Centerline Alignment | Maintains common centerline | One edge parallel to baseline |

| Flow Characteristics | Minimal turbulence | Potential for stratification |

| Pressure Drop | Gradual and symmetrical | Asymmetric, requires flow straightener |

| Parameter | Concentric Reducer | Eccentric Reducer |

| Orientation Requirement | Any rotation acceptable | Critical (must specify flat side position) |

| Air Entrapment | Possible in horizontal lines | Self-venting when properly oriented |

| Primary Applications | Vertical piping; pump discharges | Pump suctions; pipe racks |

| Space Requirements | Requires vertical clearance | Maintains pipe elevation |

| Support Considerations | Standard supports adequate | May require additional guidance |

How to choose a reducer

- Based on media characteristics: Choose stainless steel for corrosive fluids and alloy steel for high temperatures.

- Pressure requirements: Choose Sch80 or higher for high pressures and Sch5-Sch40 for low pressures.

- Installation space: Butt welding saves space, while flanges facilitate maintenance.

Summary

Concentric reducers, as an important pipe fitting, play an indispensable role in industries such as industry and construction.

By understanding their alias, structural characteristics, and application scenarios, we can better understand and use these pipe fittings, ensuring the smooth operation of various piping systems.