Pipe Connection Basics: Butt Welding Fittings vs. Socket Welding Fittings

Contents

- Preface

- What are butt-welded pipe fittings?

- What are socket-welded pipe fittings?

- Butt-welded pipe fittings

- Socket-welded pipe fittings

- Butt-welded pipe fittings vs. socket-welded pipe fittings

- Advantages and disadvantages of butt-welded pipe fittings

- Advantages and disadvantages of socket-welded pipe fittings

- Summary

Preface

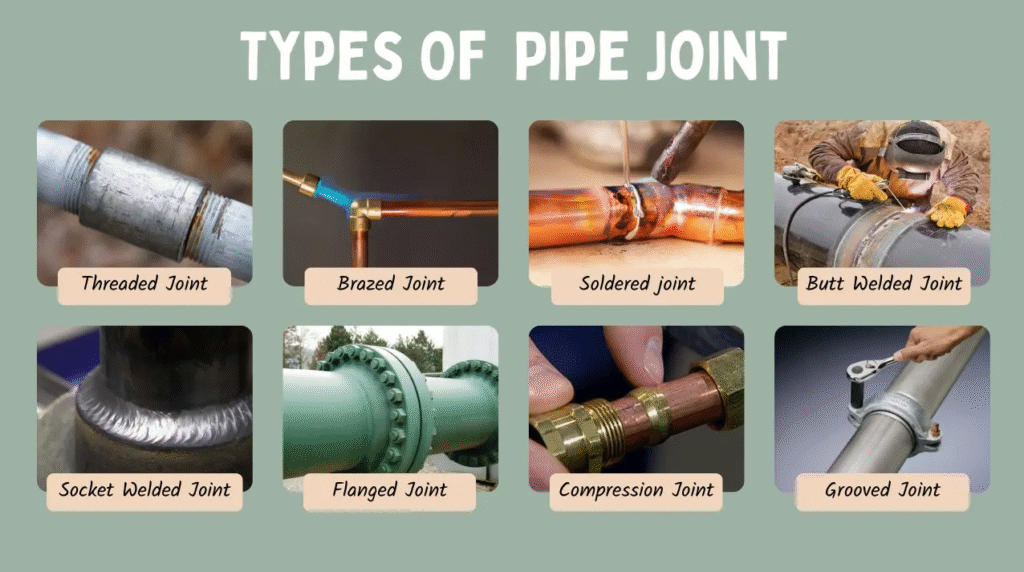

In industrial piping, butt-welded pipe fittings and socket-welded pipe fittings are the two most common types, playing a crucial role in pipe connections. However, there are differences between the two in certain scenarios, and understanding these differences helps us choose the appropriate type of fitting.

Metleader primarily manufactures butt-welded and socket-welded pipe fittings, exporting to over 80 countries and regions. We consistently prioritize product quality, which has earned us over 1000 long-term clients.

Today, this article introduces the basics of butt-welded and socket-welded pipe fittings, hoping to help you better understand them.

If you’d like to learn more about Metleader, you can follow us on YouTube and LinkedIn.

What are butt-welded pipe fittings?

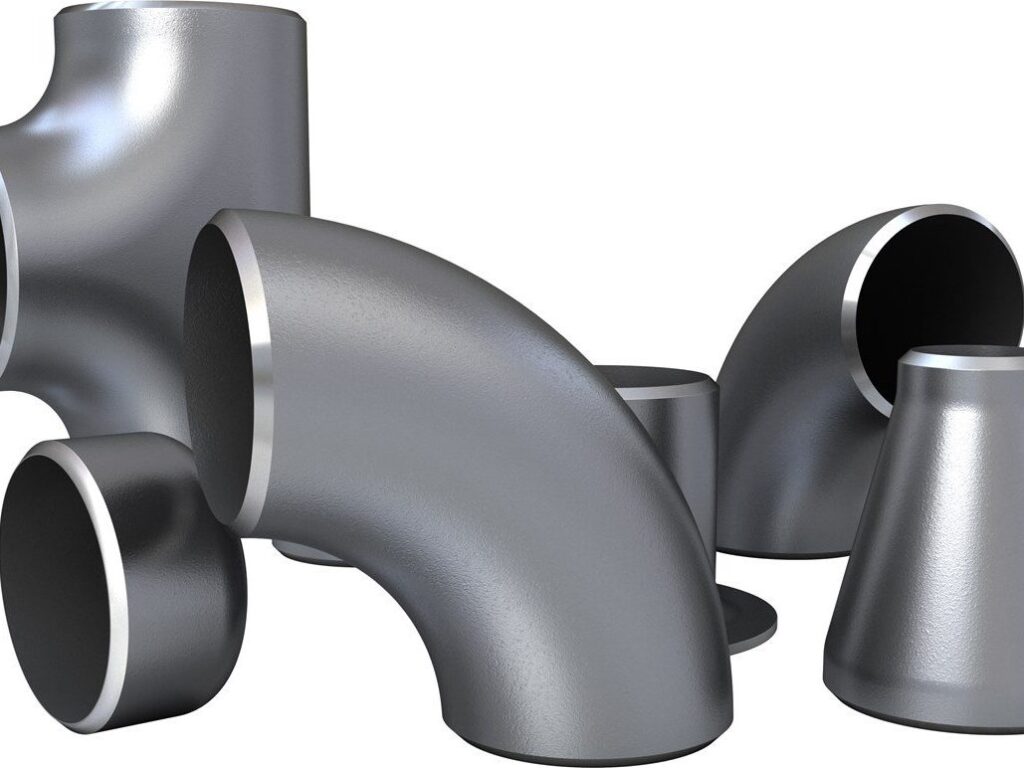

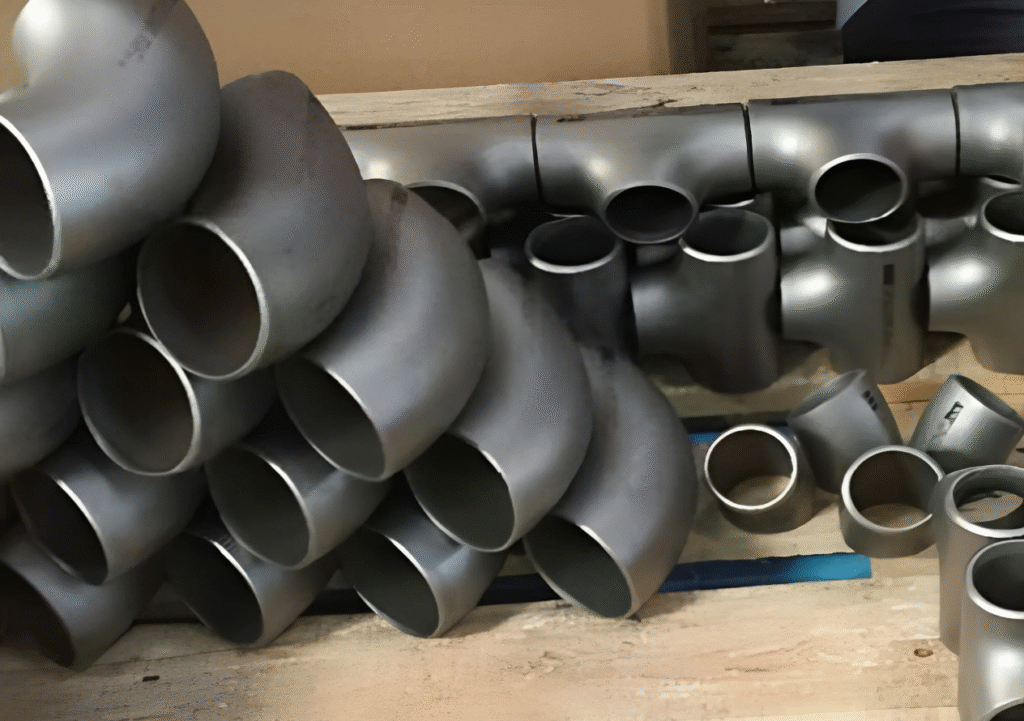

Butt-welded pipe fittings are pipe fittings connected by welding, mainly used to change the direction, branch, or reduce the diameter of pipes. According to standards, they are mainly divided into the following types: elbows, tees, reducers, and pipe caps.

What are socket-welded pipe fittings?

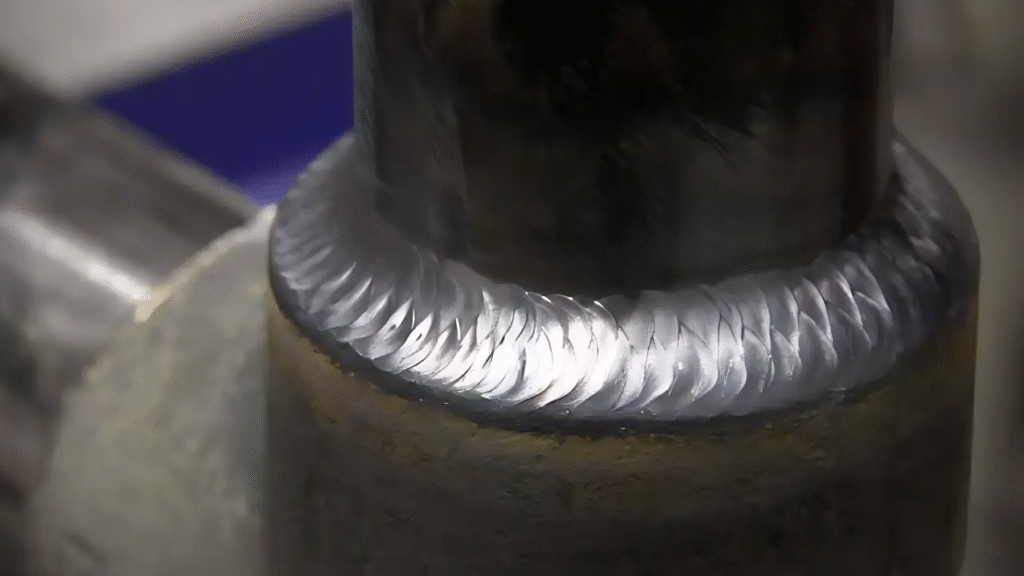

Socket welding pipe fittings are a type of pipe connection where a stainless steel pipe is inserted into the socket of the fitting and pressed against the positioning step of the socket, and then circumferentially argon-protected fusion welding is performed. The working pressure is 1.6 MPa, and it belongs to the type of jointless connection.

Butt-welded pipe fittings

Understanding the basics of butt-welded pipe fittings can help us better select suitable fittings. Below, we will focus on the standards, applications, and materials of butt-welded pipe fittings:

Butt-welded pipe fitting standards

ASME B16.9: Dimensional standard for factory-manufactured butt-welding pipe fittings, currently the most widely used standard in industry, covering nominal sizes from 1/2 inch (DN15) to 48 inches (DN1200) of carbon steel, alloy steel, and stainless steel butt-welding pipe fittings;

ASME B16.25: Butt-welding end standard, specifying beveling and dimensional tolerances for butt-welded ends;

ASME B16.28: Dimensional standard for short radius (SR, R=1.0D) and 180-degree steel butt-welding elbows;

ASTM A234/A234M: Standard for carbon steel and alloy steel butt-welding pipe fittings for medium and high temperature applications;

ASTM A403/A403M: Standard for austenitic stainless steel butt-welding pipe fittings;

MSS SP-43: Standard for stainless steel butt-welding pipe fittings for low-pressure, corrosion-resistant applications;

Applications of butt-welded pipe fittings

- Oil and Gas Industry

- Chemical and Petrochemical Industry

- Power Industry

- Shipbuilding and Marine Engineering

- Food and Pharmaceutical Industry

- Other Industrial Sectors

Classification of butt-welded pipe fittings

Stainless steel butt-welded pipe fittings: Manufactured using austenitic stainless steel or duplex stainless steel such as ASTM A403 WP304/L, 316/L, 321, and 347, conforming to ASME B16.9 production standards.

They possess excellent corrosion resistance and are suitable for industrial pipelines in high-temperature, high-pressure corrosive environments.

Carbon steel butt-welded pipe fittings: Conform to ASTM A234 material standards using WPB, WPC grade carbon steel or WP series chromium-molybdenum alloy steel butt-welded pipe fittings.

They are economical, practical, cost-effective, and possess excellent mechanical strength. Suitable for pipelines in atmospheric and vacuum distillation units of oil refineries and urban district heating pipelines.

Socket-welded pipe fittings

Unlike butt-welded pipe fittings, socket-welded pipe fittings differ in standards, applications, and materials. To better understand these differences, we will discuss the basics of socket-welded pipe fittings:

Standards of socket-welded pipe fittings

ASME B16.11: Primary standard for socket weld and threaded pipe fittings;

MSS SP-97: Standard for socket weld and threaded pipe supports;

MSS SP-83: Standard for socket weld and threaded unions;

Applications of socket-welded pipe fittings

Socket weld pipe fittings are suitable for various piping systems, especially those operating under high pressure and high temperature conditions.

Common applications include chemical, petroleum, natural gas, paper, food, and pharmaceutical industries.

Types of socket-welded pipe fittings

Austenitic stainless steel socket weld pipe fittings: Represented by F304/304L, F316/316L, and F321/321H, these fittings possess excellent corrosion resistance and toughness, resisting various acid and alkali media, and exhibiting excellent low-temperature performance.

They are widely used in industries with high corrosion resistance requirements, such as food processing, pharmaceuticals, and water treatment.

Duplex stainless steel socket weld pipe fittings: Represented by materials such as F51, F53, and F55, these fittings combine the advantages of austenitic and ferritic stainless steels, possessing both high strength and high corrosion resistance.

They have strong resistance to stress corrosion cracking and are suitable for harsh environments such as marine engineering and chemical desulfurization.

Carbon steel socket weld pipe fittings: Made of high-quality carbon structural steel, with strictly controlled chemical composition, and a low-sulfur, low-phosphorus design to avoid material brittleness and improve fatigue resistance; tensile strength ≥485MPa, yield strength ≥250MPa, and elongation ≥22% at room temperature, ensuring that the fittings are not prone to stretching or deformation under high-pressure conditions.

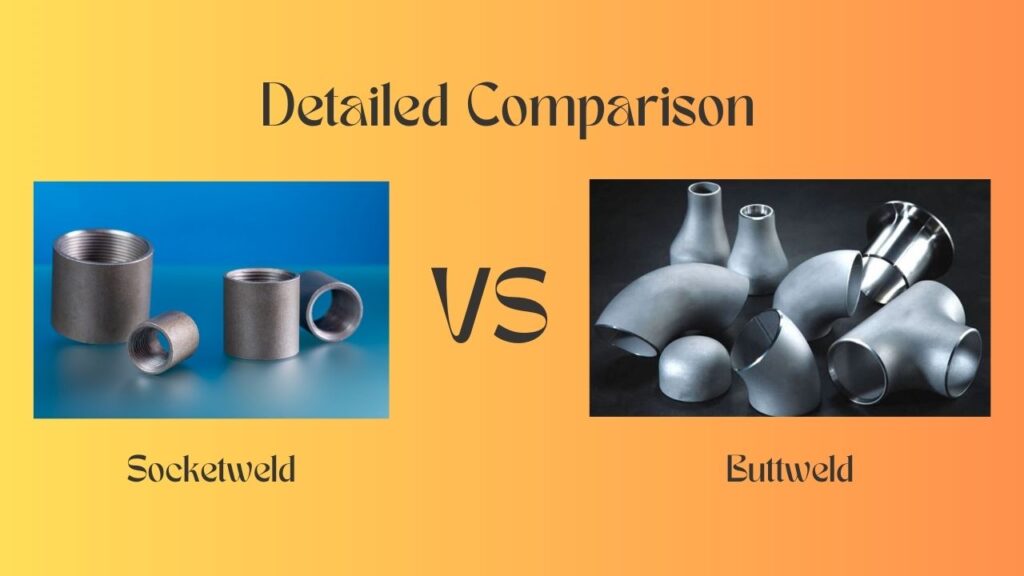

Butt-welded pipe fittings vs. socket-welded pipe fittings

| Feature | Butt Weld Fittings | Socket Weld Fittings |

| Connection Method | Beveled ends butt against pipe | Pipe inserts into socket recess |

| Joint Type | Full penetration groove weld | Fillet weld on outside |

| Gap Requirement | Maintained root gap | 1.6mm thermal expansion gap required |

| Parameter | Butt Weld Fittings | Socket Weld Fittings |

| Size Range | 1/2″ NPS and larger | Typically 1/2″ to 4″ NPS |

| Pressure Rating | Full ASME Class | Higher (Class 3000/6000 for ≤2″) |

| Inspection | RT/UT for critical service | Visual/LPT inspection usually sufficient |

| Cost Factor | Lower fitting cost, higher welding cost | Higher fitting cost, lower installation cost |

Advantages and disadvantages of butt-welded pipe fittings

| Aspect | Description |

| Advantages | 1. High Safety: Full penetration welds withstand high pressure/temperature, low leakage risk. 2. Wide Application: Suitable for small to large diameters, high pressure/temperature, corrosive media. 3. Long Service Life: 3-5+ years; excellent corrosion and fatigue resistance. |

| Disadvantages | 1. Low Installation Efficiency: Requires beveling, specialized welding, NDT; longer cycles. 2. High Cost: Higher manufacturing, installation, and maintenance costs. 3. Poor Space Adaptation: Requires ample clearance; not ideal for tight spaces. 4. Low Maintenance Flexibility: Permanent weld; difficult to disassemble or repair. |

Advantages and disadvantages of socket-welded pipe fittings

| Aspect | Description |

| Advantages | 1. High Installation Efficiency: No beveling required; standard welding; shorter cycles. 2. Low Cost: Lower manufacturing, installation, and maintenance costs. 3. Good Space Adaptation: Compact size; suitable for tight spaces; some allow for disassembly. 4. High Maintenance Flexibility: Some with unions for easy disassembly and repair. |

| Disadvantages | 1. Lower Safety: Fillet welds have limited pressure/temperature rating; higher leakage risk. 2. Narrow Application: Best for small-medium diameters, low pressure/temperature, mild media. 3. Short Service Life: 1-3 years; prone to crevice corrosion and fatigue. |

Summary

The selection between butt-welded and socket-welded pipe fittings requires comprehensive consideration of pressure rating, media characteristics, and installation conditions.

In high-pressure chemical transportation scenarios, butt welding is the preferred choice due to its material consistency and stress dispersion advantages; while in low-pressure drinking water systems or temporary facilities, socket welding offers more economical advantages due to its rapid installation characteristics.

This article details the differences and characteristics of butt-welded and socket-welded pipe fittings, helping you to make a more informed choice.

If you would like to learn more about pipe fittings and the latest prices, please contact Metleader for one-on-one technical support.