Everything You Need to Know About Thick-Walled Seamless Steel Pipes

Contents

- Preface

- What is Thick-Walled Seamless Steel Pipe?

- Classification of Thick-Walled Seamless Steel Pipes

- Key Parameters of Thick-Walled Seamless Steel Pipes

- Standards for Seamless Steel Pipe Wall Thickness

- Dimensions of Thick-Walled Seamless Steel Pipes

- Characteristics of Thick-Walled Seamless Steel Pipes

- Applications of Thick-Walled Seamless Steel Pipes

- Why Choose Metleader?

Preface

Thick-walled seamless steel pipes are widely used in industrial fields. Metleader exports tens of thousands of tons of thick-walled steel pipes annually, finding applications in oil and gas, construction, and chemical industries.

Understanding the characteristics of thick-walled seamless steel pipes can help us better select suitable pipes to meet project safety requirements and long-term operation.

Below, this article will focus on introducing the basic knowledge of thick-walled seamless steel pipes, hoping to be helpful to you.

If you would like to learn more about us and watch our videos, please follow us on YouTube and LinkedIn.

What is Thick-Walled Seamless Steel Pipe?

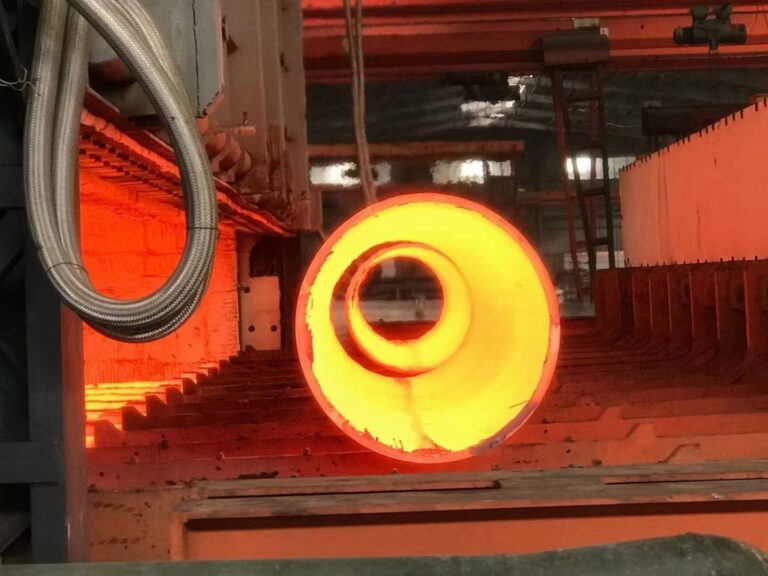

Thick-walled seamless steel pipes refer to steel pipes with a large wall thickness and no weld seams, and a large ratio of wall thickness to outer diameter.

The manufacturing process typically employs processes such as hot rolling or cold drawing, where steel billets are formed into a monolithic structure through molds at high or room temperature.

Classification of Thick-Walled Seamless Steel Pipes

Thick-walled seamless steel pipes can be classified according to their uses as follows: seamless steel pipes for general structures, seamless steel pipes for fluid transportation, seamless steel pipes for boilers, high-pressure seamless steel pipes for boilers, high-pressure seamless steel pipes for fertilizer equipment, seamless steel pipes for geological drilling, seamless steel pipes for oil drilling, seamless steel pipes for oil cracking, seamless steel pipes for oil drill collars, seamless steel pipes for automobile half-shafts, seamless steel pipes for ships, and cold-drawn and cold-rolled precision seamless steel pipes, etc.

Key Parameters of Thick-Walled Seamless Steel Pipes

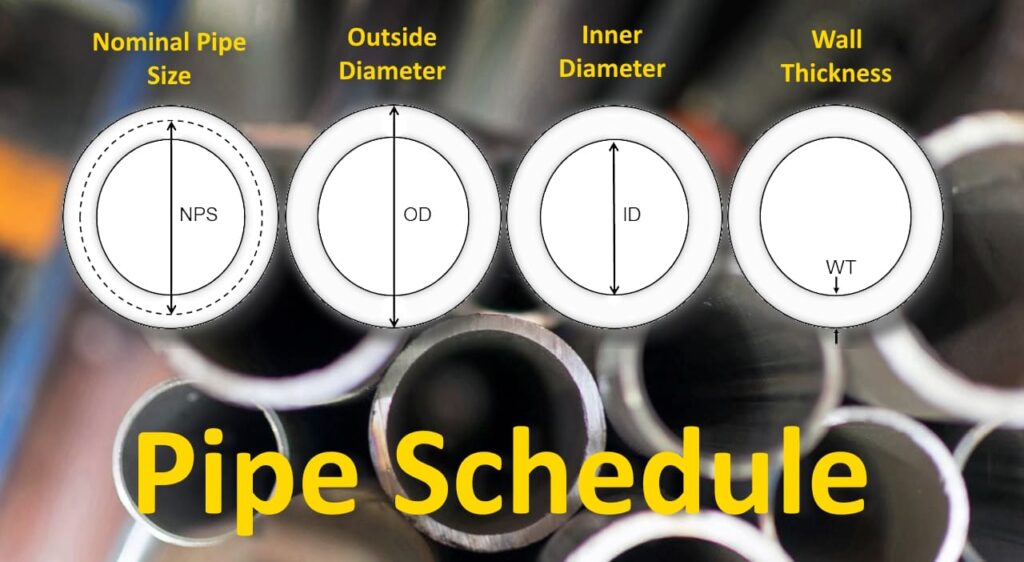

The core parameters of thick-walled seamless tubes must conform to international standards, such as:

Wall thickness range:

- Hot-rolled tubes: minimum 6mm, maximum 100mm (refer to GB/T 8163);

- Cold-drawn tubes: typically 1-40mm (refer to ASTM A333).

Outer diameter range: common 10-1200mm, special customization up to 1500mm and above.

Standards for Seamless Steel Pipe Wall Thickness

ASTM A106/A53: Applicable to piping for high-temperature service, specifying a permissible wall thickness deviation of ±12.5%.

ISO 9329: For precision applications, cold-rolled pipe wall thickness deviation is controlled within ±10%.

Dimensions of Thick-Walled Seamless Steel Pipes

In terms of size, thick-walled seamless tubing offers a wide range of specifications.

Outer diameters typically range from 1/2 inch to 24 inches, wall thicknesses from 4 mm to 60 mm, and lengths can be customized to meet specific needs, with standard lengths ranging from 6 m to 12 m, and longer lengths available in special cases.

| Nominal Size | Nominal Wall Thickness T | |||||

| DN | NPS | OD | Sch120 | Sch140 | Sch160 | XXS |

| 15 | 1/2 | 21.3 | 4.78 | 7.47 | ||

| 20 | 3/4 | 26.7 | 5.56 | 7.82 | ||

| 25 | 1 | 33.4 | 6.35 | 9.09 | ||

| 32 | 1-1/4 | 42.2 | 6.35 | 9.7 | ||

| 40 | 1-1/2 | 48.3 | 7.14 | 1015 | ||

| 50 | 2 | 60.3 | 8.74 | 11.07 | ||

| 65 | 2-1/2 | 73 | 9.53 | 14.02 | ||

| 80 | 3 | 88.9 | 11.13 | 15.24 | ||

| 100 | 4 | 114.3 | 11.13 | 13.49 | 17.12 | |

| 125 | 5 | 141.3 | 12.7 | 15.88 | 19.05 | |

| 150 | 6 | 168.3 | 14.27 | 18.26 | 21.95 | |

| 200 | 8 | 219.1 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10 | 273 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12 | 323.8 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14 | 355.6 | 27.79 | 31.75 | 35.71 | |

| 400 | 16 | 406.4 | 30.56 | 36.53 | 40.49 | |

| 450 | 18 | 457 | 34.93 | 39.67 | 45.24 | |

| 500 | 20 | 508 | 38.1 | 44.45 | 50.01 | |

| 550 | 22 | 559 | 41.28 | 47.63 | 53.98 | |

| 600 | 24 | 610 | 46.02 | 52.37 | 59.54 | |

Characteristics of Thick-Walled Seamless Steel Pipes

High Strength and Pressure Bearing Capacity: Thick-walled seamless steel pipes have a much thicker wall than ordinary steel pipes, thus possessing higher strength and pressure bearing capacity, capable of withstanding high pressure and high temperature under extreme working conditions.

Excellent Corrosion Resistance: Through the addition of alloying elements or special surface treatments, thick-walled seamless steel pipes can effectively resist the erosion of various corrosive media, extending their service life.

Good Weldability and Machinability: High-quality materials and reasonable manufacturing processes make thick-walled seamless steel pipes easy to weld and process, facilitating on-site installation and subsequent maintenance.

Structural Stability: Uniform wall thickness and excellent mechanical properties endow thick-walled seamless steel pipes with outstanding structural stability, capable of resisting external impacts and vibrations, ensuring project safety.

Applications of Thick-Walled Seamless Steel Pipes

Thick-walled seamless pipes are widely used in various engineering fields, such as petroleum, chemical, machinery manufacturing, and construction.

For example, they are used in oil well pipes in the petroleum industry and piping systems in chemical equipment; drive shafts and turbine blades in machinery manufacturing; and reinforced concrete structures in construction.

Why Choose Metleader?

Beijing Metleader Pipeline Technology Inc. is one of China’s largest manufacturers of steel pipes and fittings, providing high-quality steel pipes and fittings to over 80 countries and regions worldwide for 43 consecutive years.

We have extensive experience in both production and export, enabling us to better serve our customers and meet their technical requirements.

We own our own factory, allowing for better control over the production process and schedule, significantly improving our ability to meet our customers’ deadlines.

From raw material procurement to steel pipe forming, we conduct multiple quality inspections in each batch to ensure that all steel pipes and fittings fully comply with international standards.

Of course, if you have any other requirements, you can contact our sales consultants at any time for free one-on-one technical support.