In-depth introduction to seamless steel pipes: a guide to cooperation with Fortune 500 companies

Table of contents

- Introduction

- What is a seamless steel pipe

- Classification of seamless steel pipes

- Common specifications of seamless steel pipes

- Standards for seamless steel pipes

- Seamless steel pipes vs welded steel pipes

- Hot-rolled seamless steel pipes vs cold-rolled seamless steel pipes

- Applications of seamless steel pipes

- List of the world’s top ten seamless steel pipe manufacturers

- Summary

Introduction

Seamless steel pipes are widely used in engineering and play an indispensable role. Understanding the detailed knowledge of seamless steel pipes will help us choose seamless steel pipes suitable for the project.

Today, through this article, we will introduce the knowledge of seamless steel pipes in a comprehensive and in-depth manner.

The article will introduce the classification, application and performance comparison of seamless steel pipes with other steel pipes.

I believe that this article can serve as a cooperation guide for Fortune 500 companies, and I also hope that this article can help you purchase seamless steel pipes.

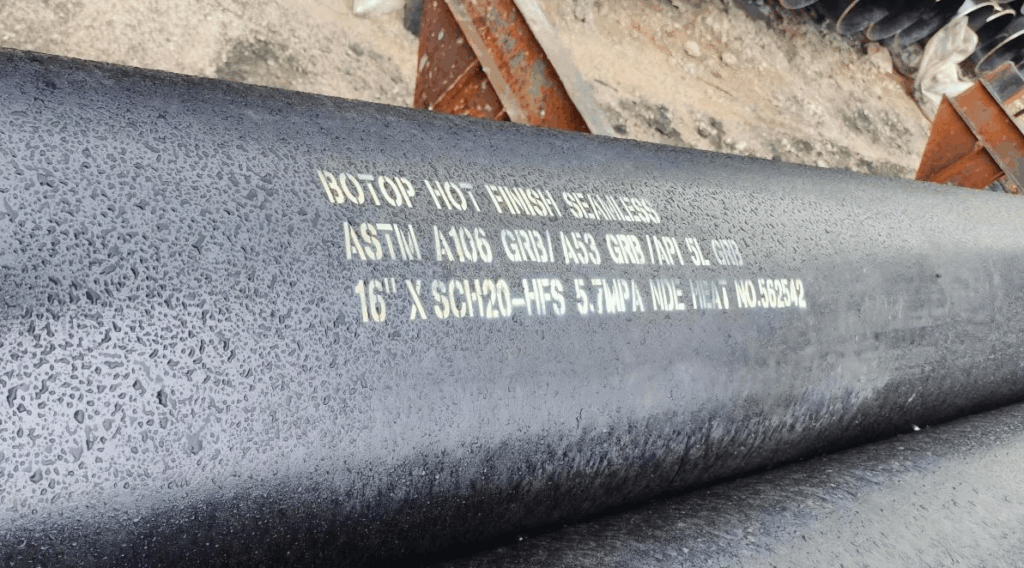

What is a seamless steel pipe

Seamless steel pipe is a steel pipe without seams along the perimeter of its cross section. It is made by perforating a whole round steel bar and has no welds on the surface.

Classification of seamless steel pipes

Seamless steel pipes can be divided into many types according to their uses, shapes and materials.

Classification by use

General purpose seamless steel pipes: used for conveying fluids, structural parts, etc., such as conveying water, gas pipelines and structural parts.

Special seamless steel pipes: used for boilers, geological exploration, bearings, acid resistance and other special purposes.

Such as seamless steel pipes for boilers, seamless steel pipes for geology and seamless steel pipes for petroleum.

Classification by shape

Round seamless steel pipe: the most common type, used for various fluid transportation and structural parts.

Special-shaped seamless steel pipe: including square, oval, triangle, hexagon, melon seed, star and other complex shapes, used for special purposes.

Classification by material

Ordinary carbon structural steel pipe: used for general fluid transportation and structural parts.

Low alloy structural steel pipe: has high strength and toughness, used for fluid transportation in high pressure and high temperature environment.

Alloy structural steel pipe: has excellent mechanical properties and corrosion resistance, used to manufacture precision mechanical parts and hydraulic equipment, etc.

Stainless acid-resistant steel pipe: has excellent corrosion resistance, used to transport corrosive fluids.

Common specifications of seamless steel pipes

| Specification | OD (mm) | WT (mm) | L (m) |

| Φ10 | 10 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ12 | 12 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ14 | 14 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ16 | 16 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ18 | 18 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ20 | 20 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ22 | 22 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ25 | 25 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ30 | 30 | 2.0, 2.5, 3.0, 4.0 | 5~8 |

| Φ32 | 32 | 2.5, 3.0, 4.0 | 5~8 |

| Φ34 | 34 | 2.5, 3.0, 4.0 | 5~8 |

| Φ36 | 36 | 2.5, 3.0, 4.0 | 5~8 |

| Φ38 | 38 | 2.5, 3.0, 4.0 | 5~8 |

| Φ40 | 40 | 2.5, 3.0, 4.0 | 5~8 |

| Φ45 | 45 | 2.5, 3.0, 4.0 | 5~8 |

| Φ50 | 50 | 2.5, 3.0, 4.0 | 5~8 |

| Φ60 | 60 | 3.0, 4.0, 5.0 | 5~8 |

| Φ63 | 63 | 3.0, 4.0, 5.0 | 5~8 |

| Φ70 | 70 | 3.0, 4.0, 5.0 | 5~8 |

| Φ73 | 73 | 3.0, 4.0, 5.0 | 5~8 |

| Φ76 | 76 | 3.0, 4.0, 5.0 | 5~8 |

| Φ89 | 89 | 3.0, 4.0, 5.0 | 5~8 |

| Φ108 | 108 | 4.0, 5.0, 6.0 | 5~8 |

| Φ114 | 114 | 4.0, 5.0, 6.0 | 5~8 |

| Φ133 | 133 | 4.0, 5.0, 6.0 | 5~8 |

| Φ159 | 159 | 4.0, 5.0, 6.0 | 5~8 |

| Φ168 | 168 | 4.0, 5.0, 6.0 | 5~8 |

| Φ219 | 219 | 6.0, 8.0, 10.0 | 5~8 |

| Φ273 | 273 | 6.0, 8.0, 10.0 | 5~8 |

| Φ325 | 325 | 6.0, 8.0, 10.0 | 5~8 |

| Φ377 | 377 | 6.0, 8.0, 10.0 | 5~8 |

Standards for seamless steel pipes

At present, there are three types of seamless steel pipe standards commonly used internationally, namely ASTM standards, DIN standards and JIS standards. Today we will focus on introducing these three standards.

ASTM standards

ASTM standards specify a variety of seamless steel pipe specifications used in different industrial fields. The following table shows some commonly used seamless steel pipe specifications and related parameters in ASTM standards.

Specifications (mm) Length (m) Wall thickness (mm)

A53 A106 6~30 5.8/6.0/11.8/12.0 1.0~10.0

A179 10~76 5.8/6.0/11.8/12.0 1.0~10.0

A192 10~101.6 5.8/6.0/11.8/12.0 1.0~10.0

A209 15~80 5.8/6.0/11.8/12.0 1.0~10.0

DIN standards

The German Institute for Standardization DIN also provides multiple specifications for the production of seamless steel pipes.

The following table shows some commonly used seamless steel pipe products and their related parameters in the DIN standard.

Specification (mm) Length (m) Wall thickness (mm)

DIN1629 13.5~762 5~7 2.3~60

DIN17175 10~1420 1~12 1.0~80

DIN2448 10.2~508 5~7 1.8~60

DIN2391 4~120 4~12 0.5~20

JIS standards

The Japanese Industrial Standards Association (JIS) also proposed specifications for the production of seamless steel pipes.

The following table shows some commonly used seamless steel pipe products and their related parameters in the JIS standard.

Specification (mm) Length (m) Wall thickness (mm)

JIS G3441 6~152 5~8 1.0~20

JIS G3454 21.7~216.3 4~5 2.0~12.0

JIS G3455 21.7~216.3 4~5 2.0~12.0

JIS G3456 21.7~216.3 4~5 2.0~12.0

Seamless steel pipes vs welded steel pipes

Here’s a concise comparison table between Seamless and Welded Steel Pipes:

| Feature | Seamless Steel Pipe | Welded Steel Pipe |

| Manufacturing | Solid billet pierced/extruded | Steel plate/coil formed & welded |

| Seam | None | Longitudinal/helical weld seam |

| Strength | Uniform strength circumference | Weld seam = potential weak point |

| Pressure Rating | Higher burst pressure | Lower burst pressure |

| Wall Thickness | More consistent | Possible variation near weld |

| Sizes (Diameter) | Smaller sizes common (up to 24″) | All sizes (especially large diameter) |

| Surface Finish | Rougher (scale) | Smoother |

| Ovality/Roundness | Higher tolerance deviation | Better dimensional control |

| Cost | Higher (complex process) | Lower (efficient process) |

| Lead Time | Longer | Shorter |

| Testing | Mandatory NDT per application | Weld seam NDT required |

| Common Applications | High-pressure: Oil/Gas, Boilers, Hydraulics | Low/med-pressure: Water, Structral, Conveyance |

Hot-rolled seamless steel pipes vs cold-rolled seamless steel pipes

Here’s a concise comparison table for Hot-Rolled vs Cold-Rolled Seamless Steel Pipes:

| Characteristic | Hot-Rolled Seamless Pipe | Cold-Rolled (Cold-Drawn) Seamless Pipe |

| Process Temperature | Above recrystallization temp (~1700°F) | Room temperature |

| Production Method | Rotary piercing → Hot rolling | Hot-rolled pipe → Cold drawing/rolling |

| Surface Finish | Rough, with oxide layer (scalings) | Smooth, precise |

| Dimensional Accuracy | Lower tolerance (±0.5-1%) | Higher tolerance (±0.1-0.3%) |

| Wall Thickness | Thicker walls achievable | Thin walls (down to 0.5mm) |

| Diameter Range | Larger diameters (20-500mm+) | Smaller diameters (1-150mm) |

| Mechanical Strength | Standard strength | Higher strength (work hardening) |

| Internal Stress | Lower residual stress | Higher residual stress (requires annealing) |

| Grain Structure | Coarser grains | Finer grains |

| Material Ductility | Higher toughness | Reduced ductility |

| Production Cost | Lower | Higher (additional processing) |

| Lead Time | Shorter | Longer |

| Common Applications | Structural, low-pressure fluid transport | Hydraulic systems, precision machinery, automotive |

Applications of seamless steel pipes

Seamless steel pipes are widely used in various industrial fields, such as petroleum, chemical industry, construction, machinery, etc.

Especially in high pressure and high temperature environments, such as refineries, chemical plants, nuclear power plants, etc., American standard seamless steel pipes have excellent performance.

List of the world’s top ten seamless steel pipe manufacturers

- Tenaris

- Vallourec

- TMK

- Nippon Steel Corporation

- JFE Holdings

- Sandvik

- Tianjin Steel Pipe

- Jiuli Group

- Interpipe

- Chelpipe Group

Summary

A comprehensive understanding of the knowledge of seamless steel pipes will help companies make the right decisions when choosing manufacturers.

The quality of seamless steel pipes is related to the safety and profitability of engineering projects, so excellent manufacturers are essential.

By reading this article, we can understand the basic knowledge of seamless steel pipes and the difference between welded steel pipes, hoping to help companies bring some help and suggestions.