Detailed explanation of pipe bending knowledge: a guide to purchasing large projects

Table of contents

- Introduction

- What is a pipe bend

- Classification of pipe bends

- Common pipe bend methods

- Quality control standards for pipe bends

- Applications of pipe bends

- Processing methods for pipe bends

- Pipe bends VS elbows

- Top 10 pipe bend manufacturers in the world

- Summary

Introduction

Pipe bending is a common method of processing metal pipes. Its standard is not only related to the quality of pipe bending, but also one of the important factors to ensure the normal operation of the pipeline system.

In actual work, appropriate processes and equipment should be selected according to the material and requirements, and strictly implemented in accordance with the standards to ensure that the quality of pipe bending meets the requirements.

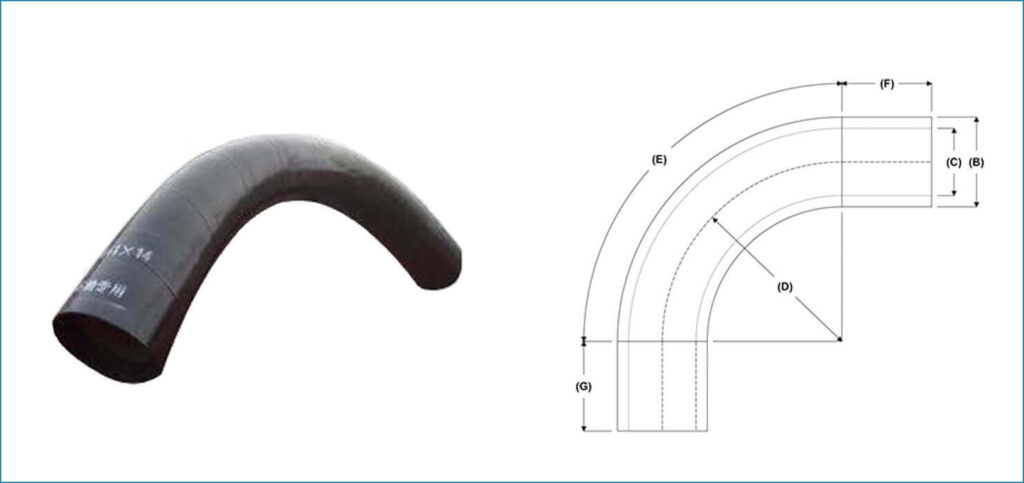

What is a pipe bend

The pipe bend is a pipe fitting that bends a straight pipe into a desired angle through a specific process. It is mainly composed of a bending section, a transition zone and a straight pipe section.

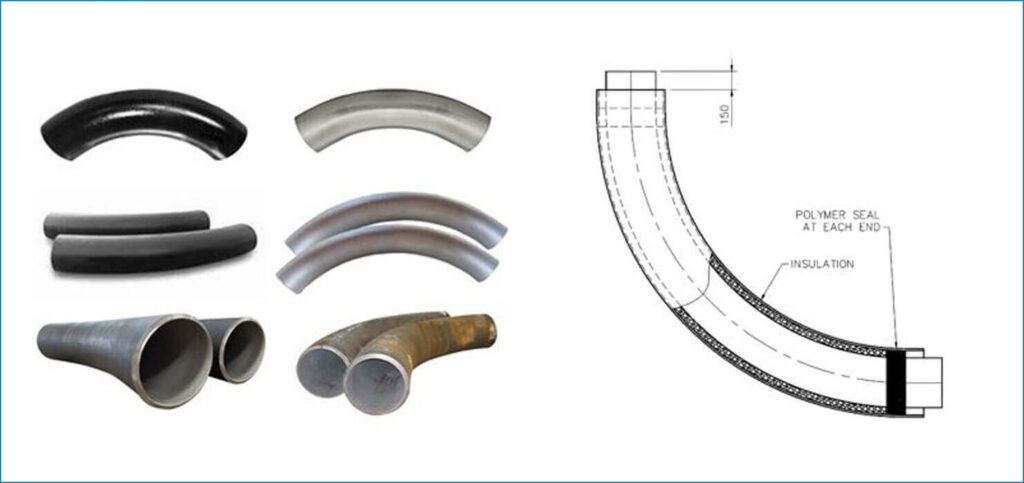

According to the material, it can be divided into carbon steel pipe bends, stainless steel pipe bends and alloy steel pipe bends.

Classification of pipe bends

Bends can be classified according to different standards:

By material: carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, etc.

By production method: pushing, pressing, forging, casting, etc.

By manufacturing standard: national standard, electrical standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

By curvature radius: long radius elbow and short radius elbow. The curvature radius of the long radius elbow is equal to 1.5 times the outer diameter of the pipe, and the curvature radius of the short radius elbow is equal to the outer diameter of the pipe.

Common pipe bend methods

- Manual pipe bending: suitable for simple scenarios, mainly through manual operation to achieve pipe bending.

- Mechanical pipe bending: with the help of mechanical equipment to complete efficient and accurate bending processing.

- Hydraulic pipe bending: rely on the internal pressure of the pipe to achieve fast and high-quality bending.

Quality control standards for pipe bends

Bending products should comply with industry standards such as GB/T12459 and ASME B16.9, with a focus on controlling key indicators such as bending angle deviation, ovality, and surface quality.

Applications of pipe bends

Bend pipes are widely used in aerospace, automobile, construction, industrial equipment, chemical and power industries.

For example, exhaust pipes, fuel pipes and brake pipes in automobiles; HVAC pipes and air conditioning systems in buildings; pipelines and pump stations in the chemical industry all require bend pipes.

Processing methods for pipe bends

- Cold bending process: suitable for thin-walled and small-diameter products, with high processing accuracy but springback.

- Hot bending process: suitable for thick-walled and large-diameter products, requiring strict control of heating temperature and time.

- Pushing process: suitable for mass production of standard angle bends.

- Welding process: used for special angle or non-standard size bends.

Pipe bends VS elbows

Here’s a straightforward comparison between Pipe Bends and Elbows:

| Feature | Pipe Bend | Elbow |

| Shape | Gradual curve (long radius) | Sharp turn (short/90° angle) |

| Made From | Cut from straight pipe | Pre-made fitting |

| Radius | ≥ 1.5× pipe diameter | ≤ 1× pipe diameter |

| Flow | Smooth (less friction) | Turbulent (pressure drop) |

| Customization | Any angle (45°, 90°, custom) | Fixed angles (45°, 90°, 180°) |

| Cost | Higher (labor + material) | Lower (mass-produced) |

| Strength | Stronger (no weak joints) | Weaker (welded joints) |

| Installation | Field-bent (needs machine) | Screwed/welded between pipes |

| Use Cases | • Long pipelines • Critical flow | • Tight spaces • Equipment connections |

Top 10 pipe bend manufacturers in the world

Top 10 Global Pipe Bending Manufacturers:

| Company Name | Founded | Annual Production | Headquarters |

| Octal Pipe Fittings | Undisclosed | Undisclosed (Global leader) | Sohar, Oman |

| Salco Products Inc | 1950s | 50,000+ tons | Aurora, Illinois, USA |

| Ramesh Steel Corporation | 1978 | 45,000+ tons | Mumbai, India |

| ETIC TUBE & PROFILES | 1995 | 30,000+ tons | Saint-Étienne, France |

| King Architectural Metals | 1970 | 25,000+ tons | Los Angeles, California, USA |

| Sunny Steel Enterprise Ltd | 1992 | 20,000+ tons | Shanghai, China |

| Sangir Plastics Private Ltd | 1987 | 18,000+ tons | Gujarat, India |

| FORNARA AG | 1960s | 15,000+ tons | Sirnach, Switzerland |

| Copier Machinery | 1997 | 400+ systems/year | Giesen, Netherlands |

| Basak Laser | 1983 | 12,000+ tons | Istanbul, Turkey |

Summary

Through the above information, we can fully understand the basic knowledge, classification, application fields, manufacturing process and material selection of pipe bending, which will help us better select and use pipe bending in practical applications.

By deeply understanding the basic principles, process flow and common methods of pipe bending, we can use this technology more skillfully and provide better products and services for all walks of life.