Carbon Steel Elbows of Different Standards (45° and 90°): Applications and Specifications

Contents

- Introduction

- What is a Carbon Steel Elbow?

- Common Carbon Steel Elbow Classifications

- Elbow Applications

- Elbow Standards

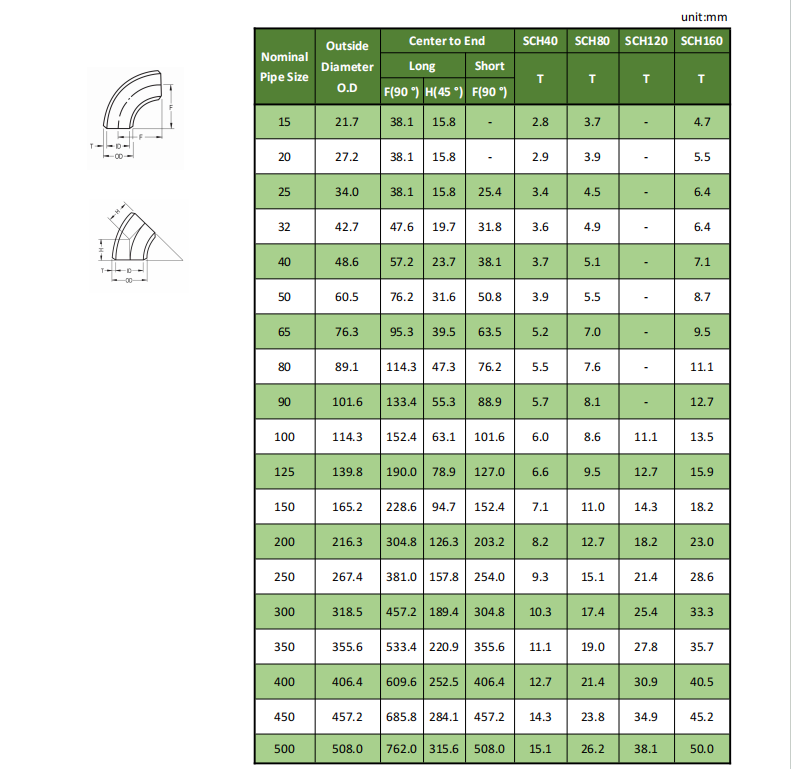

- ASME Standard Elbow Specifications

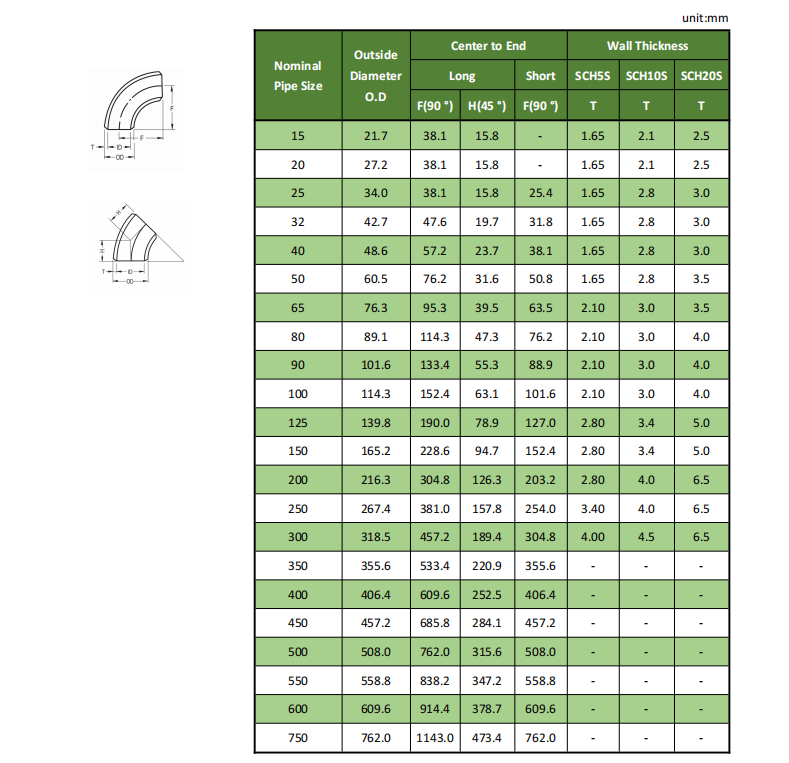

- JIS Standard Elbow Specifications

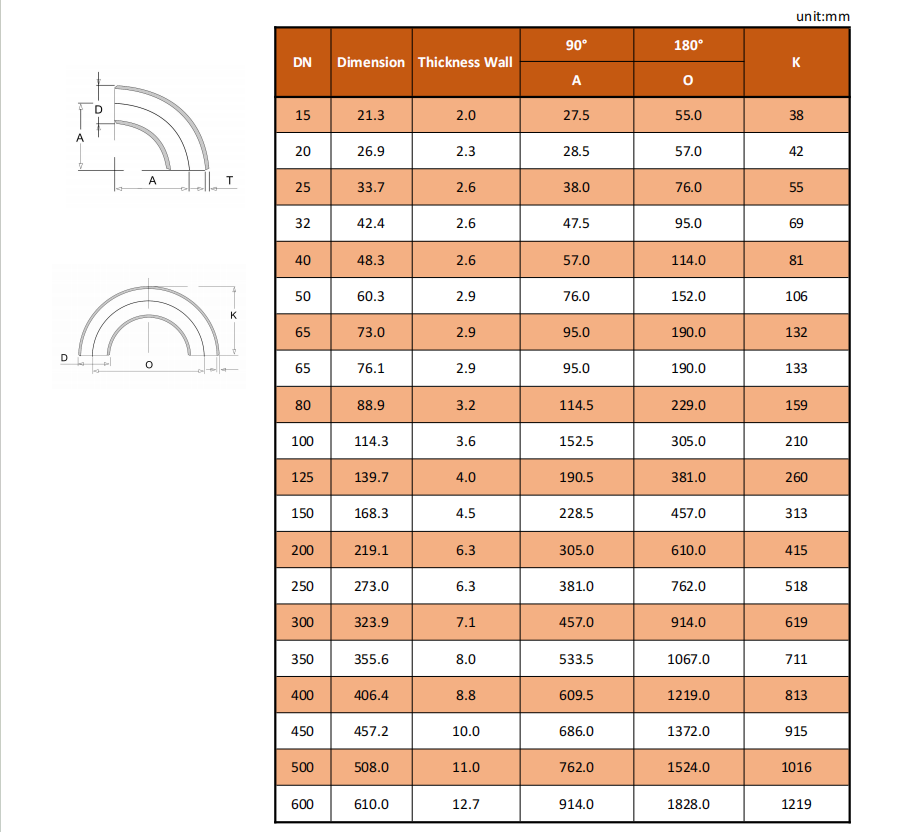

- DN Standard Elbow Specifications

- Top 10 Elbow Manufacturers in the World

- Summary

Introduction

Elbows are very common in industrial environments, especially 45° and 90° elbows.

This article focuses on the classification, specifications, applications, and manufacturers of carbon steel elbows. We hope this article will provide customers with a better understanding of carbon steel elbows.

If you are interested in our products, please subscribe to our YouTube channel and LinkedIn.

What is a Carbon Steel Elbow?

Carbon steel elbow is a connection component used in piping systems, mainly used to change the direction of the pipeline or connect different pipeline sections. It is made of carbon steel.

Common Carbon Steel Elbow Classifications

Carbon steel elbows can be divided into many types according to different classification standards.

The common types are mainly the following two:

45° Carbon Steel Elbow

The 45° carbon steel elbow is a common pipe connector, primarily used to change the direction of fluid in a piping system, specifically at a 45-degree angle.

Compared to other elbows, the 45° elbow provides a smoother turn, reducing fluid flow resistance and making it suitable for use in a variety of industrial piping systems.

90° Carbon Steel Elbow

90° carbon steel elbow is a pipe fitting used in piping systems to change the direction of the pipe, making the pipe turn 90° .

It is widely used in water supply and drainage, HVAC, gas, industrial pipelines and other fields.

Elbow Applications

- Chemical pipeline diversion;

- Building drainage systems;

- Heating, ventilation, and air conditioning (HVAC) installation;

- Oil and gas transportation;

- Food processing equipment;

- Marine piping layout;

- Agricultural irrigation systems;

- Fire protection piping configuration;

- Laboratory gas piping;

- Home renovation and decoration

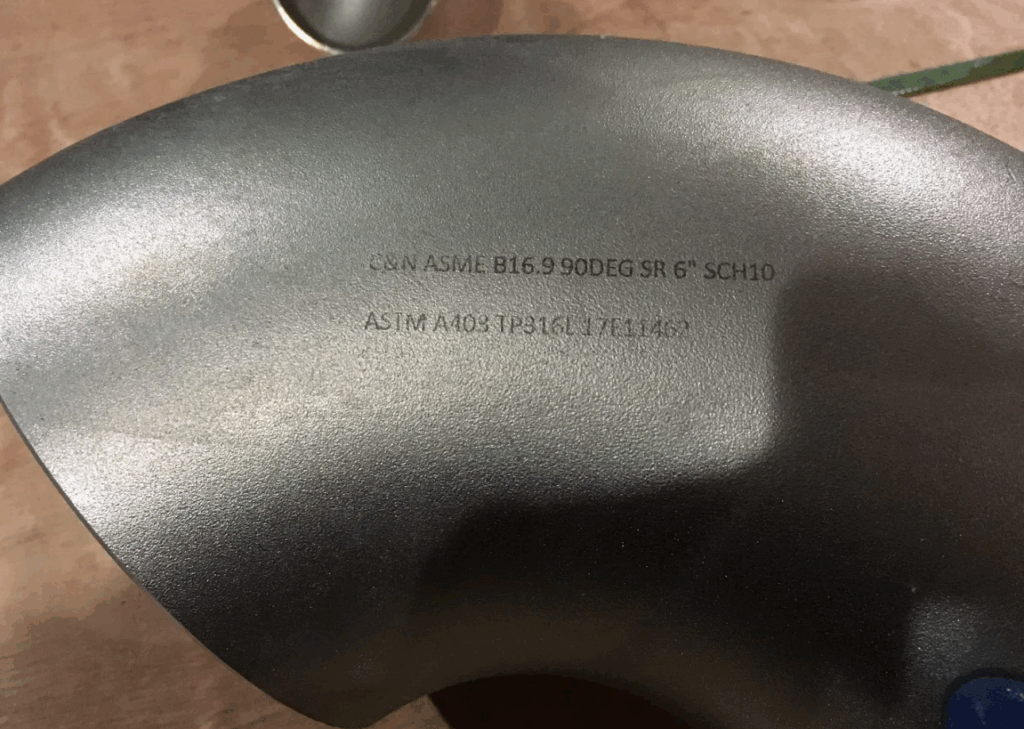

Elbow Standards

The internationally recognized elbow standards are the US national standards ANSI B16.9 and B16.28. These standards cover an outside diameter range of 1/2″ to 80″.

Generally, elbows up to 24″ are made from seamless steel pipe, while those from 26″ to 80″ are stamped from steel plate and then welded.

Wall thicknesses range from a maximum of 60mm to a minimum of 1.24mm.

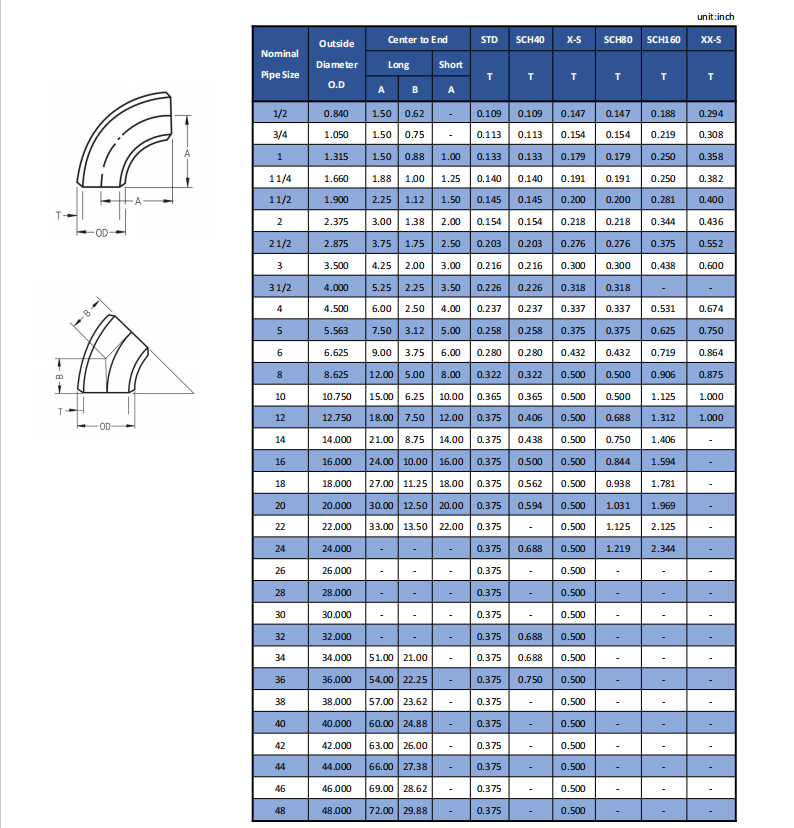

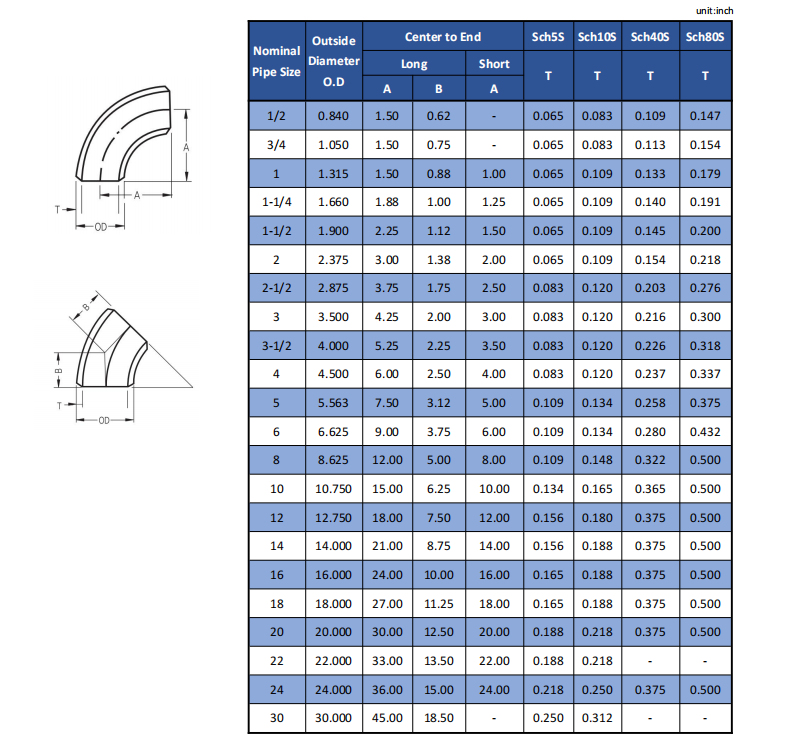

ASME Standard Elbow Specifications

JIS Standard Elbow Specifications

DN Standard Elbow Specifications

Top 10 Elbow Manufacturers in the World

| Rank | Company Name | Headquarters | Key Products & Specializations |

| 1 | Metalurgica Gerdau | São Paulo, Brazil | Large-diameter carbon steel elbows |

| 2 | Tenaris | Luxembourg | OCTG alloy steel elbows |

| 3 | Butting | Krefeld, Germany | Nickel alloy elbows |

| 4 | JFE Steel Corporation | Tokyo, Japan | High-pressure boiler elbows |

| 5 | Beijing Metleader Pipeline | Beijing, China | Stainless steel elbows; carbon steel elbows |

| 6 | ISMT Ltd | Pune, India | ASTM A234 WPB/WPC standard elbows |

| 7 | ArcelorMittal | Luxembourg | X70/X80 pipeline elbows |

| 8 | Nippon Steel | Tokyo, Japan | stainless elbows |

| 9 | Jindal SAW | New Delhi, India | Large-radius elbows |

| 10 | ChelPipe | Chelyabinsk, Russia | Heavy-wall elbows |

Summary

Through the above article, we have gained a comprehensive understanding of carbon steel elbows, particularly their specifications and applications. Therefore, when selecting carbon steel elbows, we should base our procurement on the specific requirements of the project.

Metleader, one of China’s largest elbow and pipe fitting manufacturers, supplies millions of tons of steel pipes and fittings to customers worldwide, earning unanimous recognition from our customers.

Our fittings boast a 100% quality pass rate, and we offer complete solutions tailored to each client’s project, resulting in virtually no customer complaints.

Everyone who has purchased from Metleader says: “Metleader is fantastic, and our products are excellent.”

We welcome customers interested in learning more about and purchasing elbows to contact us for inquiries and collaboration.