Introduction of blind flange

Introduction of blind flange

What is blind flange?

Blind flange is also called pipe plugs. It is a flange without a hole in the middle, used to seal the pipe mouth. There are many types of sealing surface, including plane, convex surface, concave and convex surface, tenon surface and ring connecting surface.

Material: carbon steel, stainless steel, alloy steel.

classification:

In terms of appearance, the blind flange is generally divided into plate blind flange, figure 8 blind flange, insert flange, and pad ring.

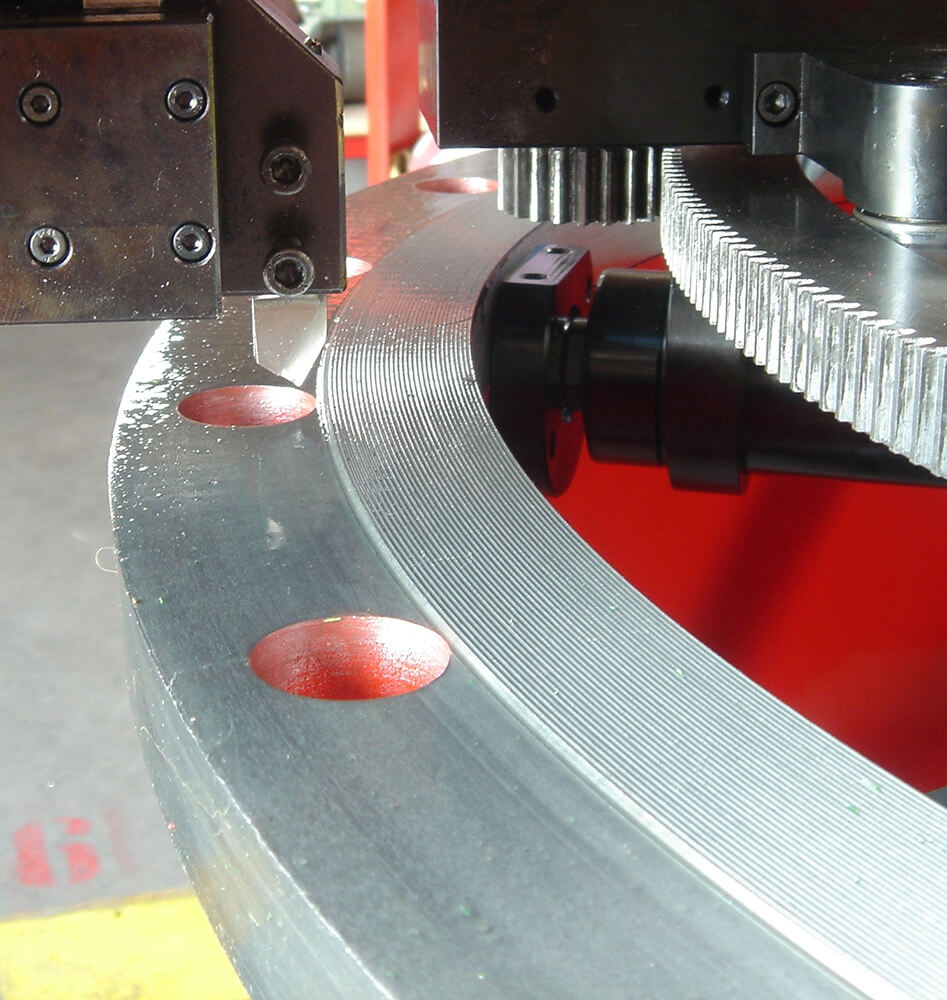

Manufacturing technique of blind flanges:

There are four kinds: forging, casting forging, plate cutting and casting. Among them, the price of forging products is the highest, followed by plate, casting and forging the lowest. Casting is one of the most inferior processes. And the quality of forging and plate is good, casting and forging is slightly worse.

Application of blind flanges:

The blind flange plays the role of isolation and cutting. Because of its good sealing performance, for the need for complete isolation of the system, generally as a reliable means of isolation. A plate blind flange is a solid circle with a handle used for systems that are normally isolated. The figure 8 blind flange has a blind flange at one end and a throttling ring at the other end. But the diameter is the same as the diameter of the pipe and does not play the role of throttling.

Figure 8 blind flange is easy to use. When isolation is required, use the blind flange end, when normal operation is needed, use the throttle ring end, it also can be used to fill the installation gap of the blind flange on the pipeline. Another feature is the obvious logo, easy to identify the installation status.

Blind flange is not galvanized when used in oil medium system, but should be hot-galvanized when used in other medium system. The minimum weight of zinc dip layer is 610g/m2, and the quality inspection of hot dip zinc is according to CB*/Z343.

Selection method of blind flanges:

The blind flange shall be set at the parts requiring isolation (cut off), such as the equipment nozzle, before and after the cut off valve, or between two flanges. Figure 8 blind flange is usually recommended. For pressing, purging and other one-time use parts can also use the plug plate (circular blind flange).