Expander flange manufacturers and suppliers from China

Where are expander flange used?

Pressure rating specifications for expander flange

What is the material of expander flange?

What should you pay attention to when purchasing expander flanges?

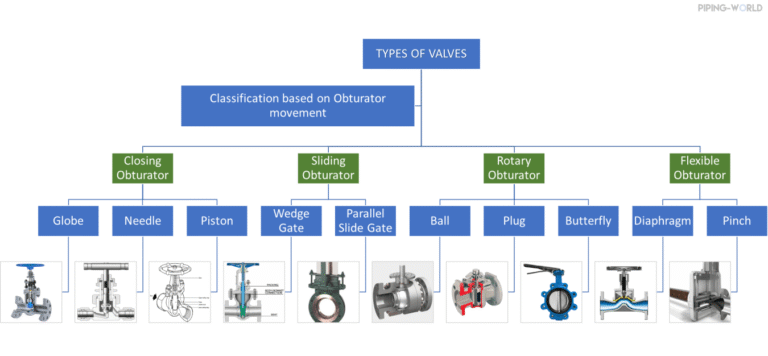

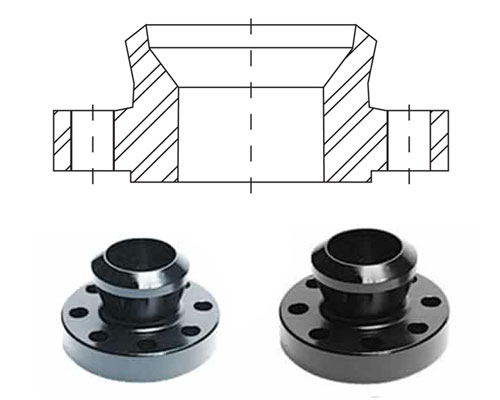

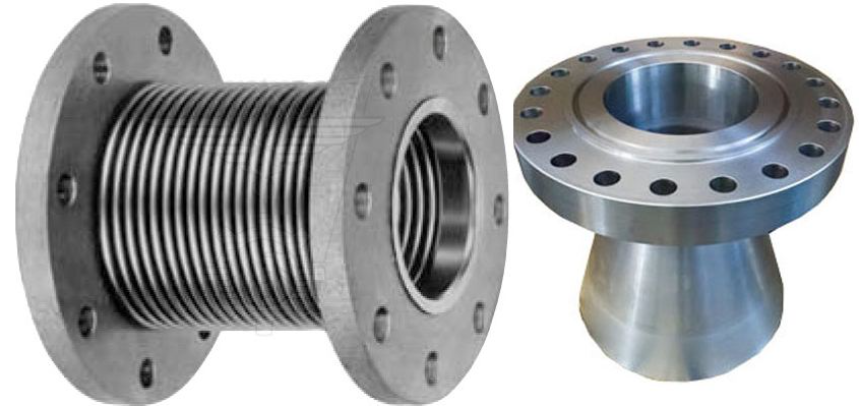

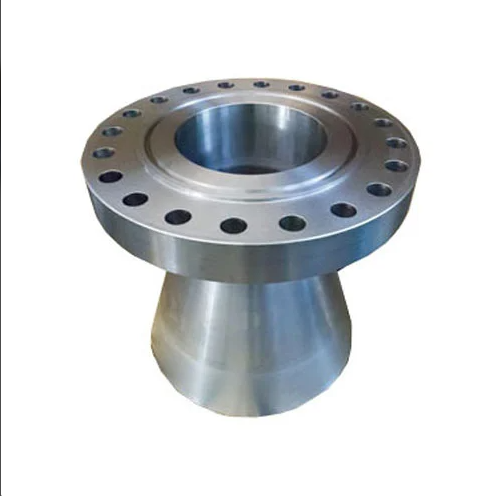

Expansion flange, used to increase the bore diameter of a pipe from any particular point to another point in order to connect the pipe to any other mechanical equipment like pumps, compressors and valves which are found to have different inlet sizes.

Expander flange is a special purpose industrial pipe flange designed to provide expanded connections to adjoining pipe or fittings.

We manufacture & supply expander flanges in nominal size 2″-30″ and pressure up to 6000# to meet your piping needs.

What is expander flange

The ASME B16.5 expansion flange is a welded neck pipe ridge used to create pipe dimensions at rib joints.

It provides a reliable method for mechanical components, siphons and valves if you have limited space or need to discuss more basic pipe sizing on a very important level.

Stainless steel expander spine prevents ribs and reducers from getting during use.

Expanded flanges are similar to necked weld flanges, but the hub is enlarged to a larger size (one or two sizes).

It provides a convenient way to access equipment, pumps and valves if you have limited space or simply need to connect to a larger pipe size.

It can replace the use of flanges and reducers.

Where are expander flange used?

Expansion flanges are used in chemical and petrochemical processing.

Expansion flanges are used in electronic products. Expansion flanges are used in processing equipment to maintain product purity when handling foods, synthetic fibers.

Expansion flanges are used in marine and offshore engineering.

Expansion flanges are available in a variety of sizes and materials.

Pressure rating specifications for expander flange

Expansion flanges are pressure rated and sized to ANSI or ASME B16.5 specifications, which are primarily available in raised or flat faces (RF or FF).

Reducing flanges, also known as reducing flanges, have the exact opposite function compared to expansion flanges, meaning they are used to reduce the bore diameter of the pipe.

The bore size of the running tube can be easily reduced, but not more than 1 or 2 sizes.

If an attempt is made to reduce beyond this range, a solution based on a combination of butt-welded reducers and standard flanges should be used.

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504 , BS4504, BS1560, BS10

What is the material of expander flange?

- Stainless Steel : ASTM A 182, A 240

Grade : F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, 2507 Super Duplex stainless steel UNS S32750

- Carbon Steel : ASTM A 105, ASTM A 350

- Alloy Steel : ASTM A 182, GR F1, F11, F22, F5, F9, F91

- Nickel Alloys : Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276,Cupro Nickel,Alloy 20

- Non Ferrous Alloys : Copper, Brass,Aluminum Bronze,Titanium,Phosphor Bronze & Gunmetal.

What should you pay attention to when purchasing expander flanges?

If you need to buy Carbon Steel Expansion Flanges, ideally cost in China, please check our Expansion Flanges including BS 4504 PN10 Expansion Flange, Hydraulic Rib Expansion Flange and Monel Expansion Flange cost.

Nickel alloy expanded butt welding flange to the United Kingdom, the United States, Sweden, Israel, France, Italy, Canada, United Arab Emirates, Australia, Germany, Russia, Oman, Kuwait, Qatar, Iran, Turkey, Egypt, Bahrain, Indonesia, Malaysia, Singapore , Thailand, Sri Lanka and Saudi Arabia.

There is no doubt that we can provide Expansion Flange, best case scenario, cost as we are one of the most amazing Expansion Flange Suppliers and Manufacturers in China.