Welded Steel Pipe Guide: Standards, Applications, Advantages and Disadvantages

Contents

- Introduction

- What is welded steel pipe?

- Classification of welded steel pipe

- Applications of welded steel pipe

- Standards for welded steel pipe

- Welded steel pipe manufacturing process

- Welded steel pipe vs. seamless steel pipe

- How to choose a welded steel pipe

- FAQ

- Summary

Introduction

As a vital component of modern industry, welded steel pipes have always played an indispensable role. With the rapid development of industry, their use is becoming increasingly common.

Depending on the production process, steel pipes are primarily divided into two categories: seamless steel pipes and welded steel pipes. Each type of steel pipe has its own unique characteristics and is suitable for different applications.

Today, we will focus on the basics of welded steel pipes, including classification, applications, processes, and common issues.

We hope this article is helpful. If you would like to learn more about Metleader, you can follow us on YouTube or LinkedIn.

What is welded steel pipe?

Welded steel pipe is made by bending steel plates or steel strips into shape and then welding the seams under high temperature or pressure.

Classification of welded steel pipe

According to the weld form and production process, welded pipes can be divided into the following categories:

LSAW

Production Process: Steel plates are directly coiled and then formed using submerged arc welding (SAW) or high-frequency electric resistance welding (ERW).

Features: Straight welds and high pressure-bearing capacity, commonly used in long-distance oil and gas pipelines.

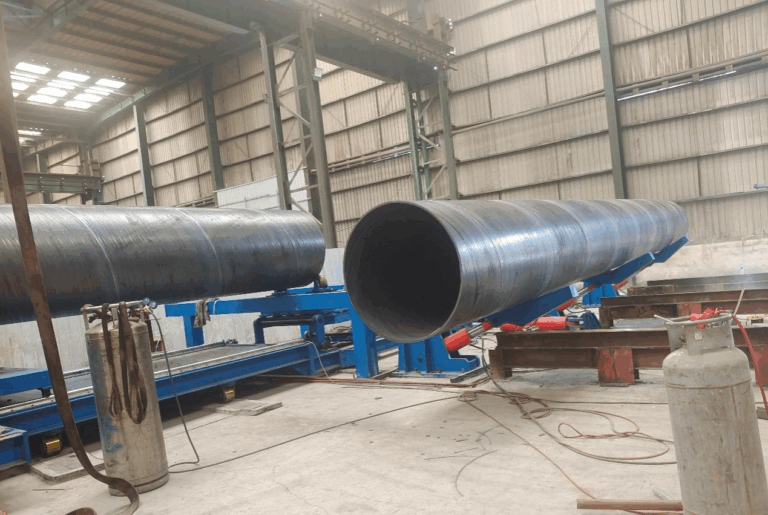

SSAW

Production Process: The steel strip is spirally coiled and continuously welded, resulting in a spiral weld.

Features: Excellent bending resistance, suitable for large-diameter pipes (e.g., diameter ≥ 508mm).

Galvanized welded pipe

Process supplement: Hot-dip galvanizing on the surface of ordinary welded pipes can improve corrosion resistance and increase service life to 20-30 years.

Applications of welded steel pipe

Welded steel pipe is a type of steel pipe manufactured with advanced technology, offering stable performance, high strength, corrosion resistance, and high-temperature resistance.

It is used in a wide range of applications, including oil, gas, and chemical pipelines; aerospace gas pipelines; construction engineering; and bridge engineering.

Standards for welded steel pipe

The quality standards for welded steel pipes are primarily categorized into internationally accepted specifications and domestic industry standards.

API 5L: The core standard for oil and gas pipelines, requiring a tensile strength of ≥415 MPa (X60 grade) and a Charpy impact test temperature limit of -20°C.

ASTM A53: The American Society for Testing and Materials standard, divided into grades A and B. Grade B steel pipe must have a yield strength of ≥240 MPa.

Welded steel pipe manufacturing process

Forming Process

ERW Steel Pipe: The steel strip is gradually bent into a round tube by multiple sets of rollers, with forming speeds reaching 20-40 m/min.

Spiral Welded Pipe: The steel strip is continuously coiled at a spiral angle, suitable for large-diameter pipes (diameters over 3 m).

Welding Technology

High-Frequency Resistance Welding (ERW): Utilizes a high-frequency current (100-400 kHz) to heat the edges until they are molten, then welds under pressure at temperatures of approximately 1300-1400°C.

Submerged Arc Welding (SAW): Utilizes a flux-coated arc, suitable for thick-walled pipes (wall thickness ≥ 6 mm), with slower welding speeds (approximately 1-3 m/min).

Weld Heat Treatment

Normalizing or tempering (temperature 500-650°C) eliminates welding stresses and improves toughness.

Sizing and Straightening: A sizing machine adjusts the outer diameter tolerance of the steel pipe (within ±0.5%), while a straightening machine corrects straightness (deviation ≤ 1 mm/m). End surface processing: chamfering or beveling to facilitate on-site connection.

Welded steel pipe vs. seamless steel pipe

| Parameter | Welded Steel Pipe | Seamless Steel Pipe |

| Manufacturing | Formed by rolling sheet & welding | Extruded from solid billet |

| Max Pressure | Lower (weld seam weakness) | Higher (homogeneous structure) |

| Size Range | Up to 150″ diameter | Typically ≤24″ diameter |

| Wall Consistency | ±7.5% thickness variation | ±5% thickness variation |

| Cost | 30-50% cheaper | More expensive |

| Lead Time | Shorter production | Longer manufacturing process |

| Parameter | Welded Steel Pipe | Seamless Steel Pipe |

| Weld Inspection | Required (RT/UT) | Not applicable |

| Corrosion Risk | Higher at weld seam | Uniform resistance |

| Applications | Water lines, structural | High-pressure, critical service |

| Standards | API 5L, ASTM A53 | ASTM A106, API 5CT |

| Ovality | ±1.0% tolerance | ±0.5% tolerance |

How to choose a welded steel pipe

When selecting welded steel pipe, consider the following factors:

- Operating Environment: Select the appropriate material based on the environmental conditions (such as temperature, pressure, and medium) in which the welded steel pipe will be used to ensure its normal service life.

- Load: Select the appropriate specifications and materials based on the size and nature of the load to ensure the pipe’s load capacity.

- Installation Method: Depending on the installation method, select the appropriate specifications and materials to ensure the pipe meets the required requirements.

- Cost-Effectiveness: Select specifications and materials that are reasonably priced, ensuring the pipe meets the required requirements.

FAQ

Are Welded Pipes Reliable?

The reliability of welded pipes is contingent on the quality of manufacturing and the materials used. When produced under stringent quality control protocols, welded pipes exhibit commendable integrity and durability.

They undergo extensive testing, including hydrostatic testing and non-destructive examinations like ultrasonic or radiographic testing, to verify the welded seam’s strength and detect any potential defects.

How to Verify the Quality of a Welded Pipe?

Ensuring the quality of a welded pipe involves a series of rigorous inspections. Non-destructive testing (NDT) methods like ultrasonic testing use sound waves to detect inconsistencies in the weld, guaranteeing its durability without compromising the pipe’s integrity.

Similarly, radiographic testing employs X-rays to uncover internal imperfections, offering a thorough analysis of the weld.

Are There Environmental Benefits to Using Welded Pipes?

An often overlooked advantage of welded pipes lies in their environmental impact. Many welded pipes are crafted from recycled materials, showcasing a commitment to sustainable practices in manufacturing.

Moreover, at the end of their operational life, these pipes are recyclable, contributing to a circular economy and reducing waste in the process.

Summary

Through the above introduction, we now have a very comprehensive understanding of welded steel pipes. We believe that next time you choose a welded steel pipe product, you can make a better choice.

Metleader has over 40 years of manufacturing experience and is deeply familiar with welded steel pipes.

Our products are exported to over 80 countries and regions.

To purchase welded steel pipes and learn about the latest prices, please send us an inquiry.