SMLS, ERW, LSAW, SSAW steel pipe: Applications, characteristics and differences

Contents

- Introduction

- SMLS vs ERW Pipe

- ERW vS LSAW vS SSAW Pipe

- Characteristics of Seamless Steel Pipe

- Applications of ERW

- LSAW Process

- Characteristics of ERW Steel Pipe

- Pipe Types

- Steel Pipe Standards

- How to Order Steel Pipe

- Summary

Introduction

In the oil and gas industry, steel pipes play a vital role, indispensable in every process. Therefore, choosing the right steel pipe supplier is crucial.

As China’s largest steel pipe manufacturer, Metleader provides high-quality steel pipe products worldwide.

We offer API quality inspection certificates and ISO certifications.

This article provides detailed information on seamless steel pipe, ERW pipe, LSAW pipe, and SSAW pipe, hoping to help customers make informed choices.

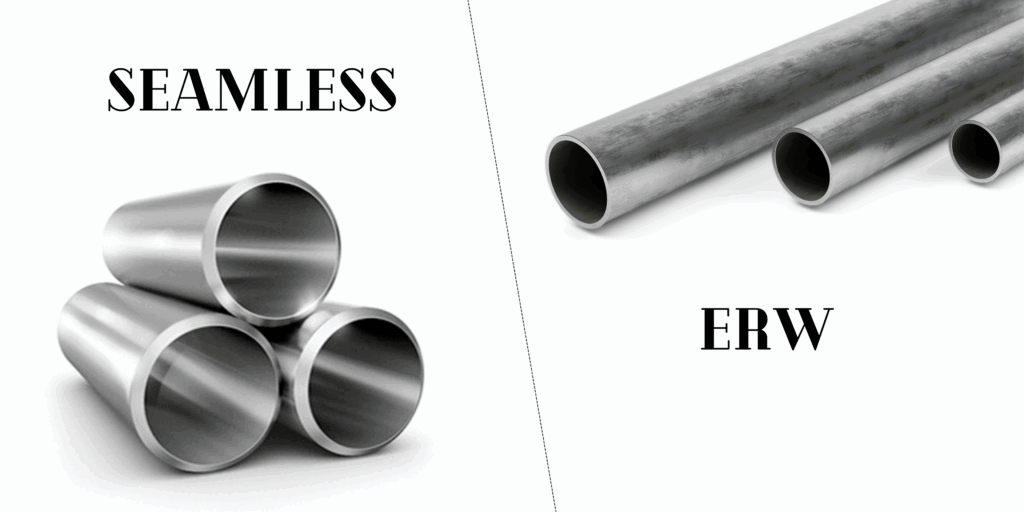

SMLS vS ERW Pipe

ERW steel pipe differs significantly from seamless steel pipe in terms of production process, performance, and application.

Production Process

ERW steel pipe is produced using electric resistance welding. Seamless steel pipe, on the other hand, is produced using hot rolling or cold drawing, and has no internal welds.

Performance Characteristics

ERW steel pipe has a uniform wall thickness that can be controlled within tight tolerances, and the mechanical properties of the weld area match those of the parent material.

The lack of welds in seamless steel pipe provides improved integrity and uniformity, allowing it to withstand greater pressure and temperature fluctuations.

Applications

ERW steel pipe is primarily used for transporting fluids such as oil and natural gas, as well as for structural applications.

Seamless steel pipe is more commonly used in high-pressure, high-temperature, and high-intensity environments, such as in the petroleum, chemical, and aerospace industries.

ERW vS LSAW vS SSAW Pipe

ERW

Features: Smooth welds, high production efficiency, and low cost.

Size Range: Diameters typically range from 20mm to 610mm, with wall thicknesses of 1.0 to 20.0mm.

Applications: Building structures and low-pressure fluid transportation (e.g., water pipes).

SSAW

Features: Spiral welds, strong pressure-bearing capacity, and suitable for large-diameter production.

Size Range: Diameters range from 219mm to 3000mm, with wall thicknesses of 5 to 25mm.

Applications: Long-distance oil and gas pipelines and pile foundation projects.

LSAW

Features: High-quality welds, suitable for high-pressure environments.

Size Range: Diameters range from 406mm to 1600mm, with wall thicknesses of 6 to 40mm.

Applications: Deep-sea oil and gas pipelines and large pressure vessels.

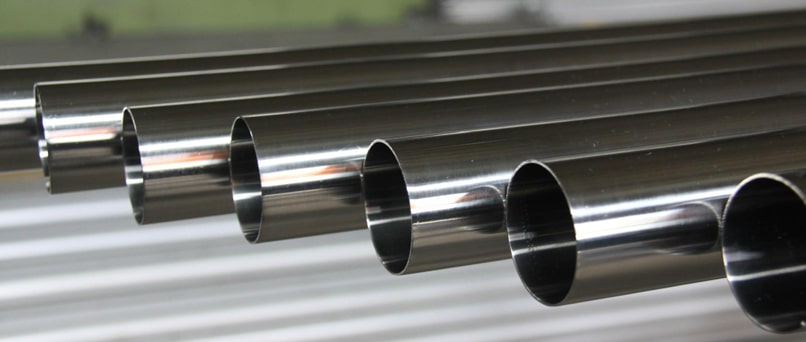

Characteristics of Seamless Steel Pipe

Seamless steel pipe is a type of steel pipe manufactured using a different manufacturing process than ordinary steel pipe. It is produced using cold drawing and cold rolling processes.

It has the following characteristics:

Seamless: Seamless steel pipe has higher strength and pressure resistance.

High Strength: The manufacturing process of seamless steel pipe determines its higher strength and pressure resistance.

High Temperature Resistance: Seamless steel pipe has excellent high temperature resistance and can operate in high temperature environments for long periods without deformation or fracture.

Corrosion Resistance: Seamless steel pipe is made of special materials with excellent corrosion resistance, which allows it to be used in corrosive environments for a long time.

Applications of ERW

- Construction industry

- Fluid transportation

- Oil and gas industry

- Machinery manufacturing

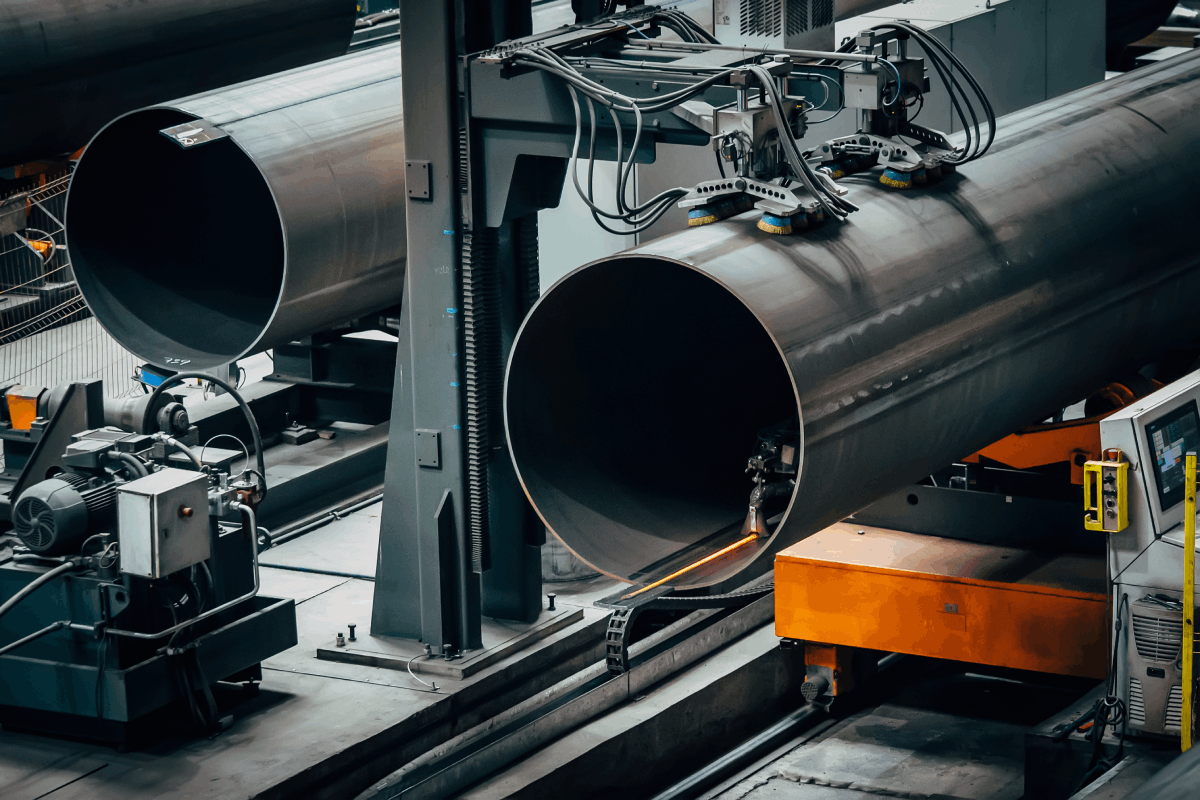

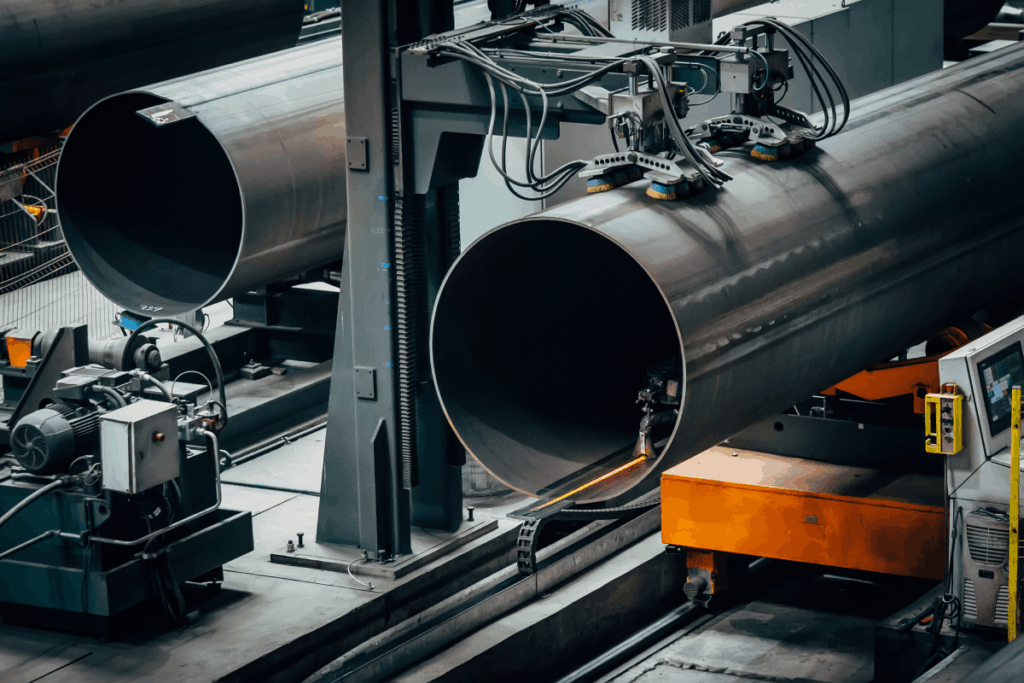

LSAW Process

The production of LSAW steel pipes involves the following steps:

First, the steel plate undergoes pre-treatment, including rust removal and cutting.

Next, the steel plate is rolled into a tube using a forming machine and pre-welded.

Finally, the tube is longitudinally welded using a submerged arc welder.

Finally, weld seam preparation, non-destructive testing, and subsequent processing are performed to ensure the tube meets quality standards.

Characteristics of ERW Steel Pipe

High Production Efficiency:

ERW welded steel pipe utilizes advanced welding technology, enabling rapid and continuous production of large quantities of steel pipe, significantly improving production efficiency compared to other types of steel pipe production methods.

High Dimensional Accuracy:

Through advanced welding processes and equipment control, ERW welded steel pipes achieve high dimensional accuracy, with minimal deviations in diameter, wall thickness, and other dimensions, meeting the requirements of various high-precision engineering projects.

Excellent Surface Quality:

Advanced welding processes and equipment are used during the welding process, resulting in a smooth surface with no visible weld marks, resulting in excellent appearance quality, eliminating the need for extensive surface treatment.

Wide Range of Materials:

ERW welded steel pipes can be produced using a variety of steel materials, including carbon steel, low-alloy steel, and stainless steel, meeting the material requirements of various applications.

Pipe Types

The oil and gas industry uses three main types of steel pipe: seamless, ERW, and LSAW.

Seamless pipe is made from a solid steel billet, which is heated and then pushed and pulled through a die to form a hollow tube without weld seams.

ERW pipe is produced using a cold forming process, where the steel is coiled into a cylindrical shape and then welded together using an electric current.

LSAW pipe is made from steel plates that are bent and welded along their length, with weld seams either straight (longitudinal) or spiral.

Steel Pipe Standards

ASME has published several standards covering the dimensions of pipe made from various materials:

- ASME B36.10: Welded and seamless carbon and alloy steels.

- ASME B36.19: Stainless steels.

- ASME B36.20: Metallic materials for general use.

- ASME B36.21: Nonmetallic materials for general use.

How to Order Steel Pipe

When ordering steel pipe, you need to specify several key pieces of information to ensure you receive the right product for your application:

Material: Please specify the material grade, such as carbon steel (A106 or A53), alloy steel (A335), stainless steel (A312), or nickel alloy (B444).

Size: Please specify the nominal pipe size (NPS) and wall thickness in either the wall thickness schedule (Sch) or inches or millimeters.

Length: Please specify the required length, such as single random (SRL), double random (DRL), or specific cut length.

End Finish: Please specify the finish of the pipe ends, such as plain end (PE), bevel end (BE), threaded (TE), threaded and coupled (T&C), or grooved.

Quantity: Please specify the total quantity required (in pieces or feet).

Testing and Certification: If any specific testing or certification is required, such as a mill test report (MTR), material test report (MTR), or material positive identification (PMI), please ensure it is included in your order.

Delivery: Please specify your desired delivery date and address.

If you have any special requirements, please be sure to inform the supplier.

Summary

Choosing the right steel pipe is a crucial decision; its quality determines the operational safety, efficiency, and profitability of your project.

Whether you need seamless steel pipe, ERW pipe, LLSW pipe, or SSAW pipe, we offer a complete solution.

With our extensive inventory, global sourcing network, and advanced processing capabilities, we can provide the pipe you need, when and where you need it.