Common English abbreviations for steel pipes and fittings

Do you know the English abbreviations for steel pipes and pipe fittings? When you see them, do you immediately understand what they mean?

This is crucial for beginners, as knowing these abbreviations helps us better understand and comprehend the material.

In this article, we’ve listed some common English abbreviations used in the steel pipe and pipe fittings industry, hoping this will be helpful.

For more information on pipe fittings, follow us on YouTube and LinkedIn.

Steel pipes & fittings

- P —— Pipe

- EL —— Elbow

- ELL —— Long radius elbow

- ELS —— Short radius elbow

- MEL —— Mitre elbow

- REL —— Reducing elbow

- T —— Tee

- LT —— Lateral tee

- RT —— Reducing tee

- R —— Reducer

- CR —— Concentric reducer

- ER —— Eccentric reducer

- CPL —— Coupling

- FCPL —— Full coupling

- HCPL —— Half coupling

- RCPL —— Reducing coupling

- BU —— Bushing

- UN —— Union

- HC —— Hose coupler

- SE —— Stub end

- NIP —— Pipe nipple or straight nipple

- SNIP —— Swaged nipple

- CP —— Cap

- PL —— Plug

- BLK —— Blank

- SB —— Spectacle blind (blank)

- RP —— Reinforcing pad

flange

- WNF – Welding neck flange

- SOF——Slip-on flange

- SWF——Socket-welding flange

- T——Threaded flange

- LJ——Lapped joint flange

- REDF – Reducing flange

- BF——Blind flange

- FSF——Flange scaling face

- FF——Flat face

- RF——Raised face

- MFF——Male and female face

- LF——Female face

- LM——Male face

- RJ——Ring joint face

- TG——Tongue and groove face

- TF——Tongue face

- GF——Groove face

gasket

- G —— Gasket

- NMG —— Non-metallic gasket

- AG —— Asbestos gasket

- RG —— Rubber gasket

- TEG —— PTFE envelope gasket

- SMG —— Semimetallic gasket

- MJG —— Meta-jacket gasket

- SWG —— Spiral wound gasket

- MG —— Metallic gasket

- FMG —— Flat metallic gasket

- SMSG —— Solid metal serrated gasket

- LER —— Lens ring gasket

- OCR —— Octagonal ring gasket

- OVR —— Oval ring gakset

- IR/OR —— Inner ring and outer ring

- IR —— Inner ring

- OR —— Outer ring

Fasteners & Valves

- B —— Bolt

- NU —— Nut

- TB —— Turnbuckle

- WSR —— Washer

- SWSR —— Spring washer

- GV —— Gate valve

- GLV —— Globe valve

- CHV —— Check valve

- BUV —— Butterfly valve

- BAV —— Ball valve

- PV —— Plug valve (cock)

- CV —— Control valve

- SV —— Safety valve

- RV —— Pressure reducing valve

- ST —— Steam trap

- PRV —— Pressur relief valve

- BV —— Breather valve

- NV —— Needle valve

Materials and grades

- M —— Metallic material

- CS —— Carbon steel

- CAS —— Cast steel

- FS —— Forged steel

- AS —— Alloy steel

- SS —— Stainless steel

- AUST —— Austenitic stainless-steel

- CI —— Cast iron

- MI —— Malleable iron

- DI —— Ductile iron

- AL —— Aluminum

- BRS —— Brass

- BRZ —— Bronze

- CU —— Copper

- LAS —— Low alloy steel

- FLAS —— Forged low alloy steel

- CLAS —— Cast low alloy steel

- THK —— Thickness

- SCH —— Schedule number

- STD —— Standard

- XS —— Extra strong

- XXS —— Double extra strong

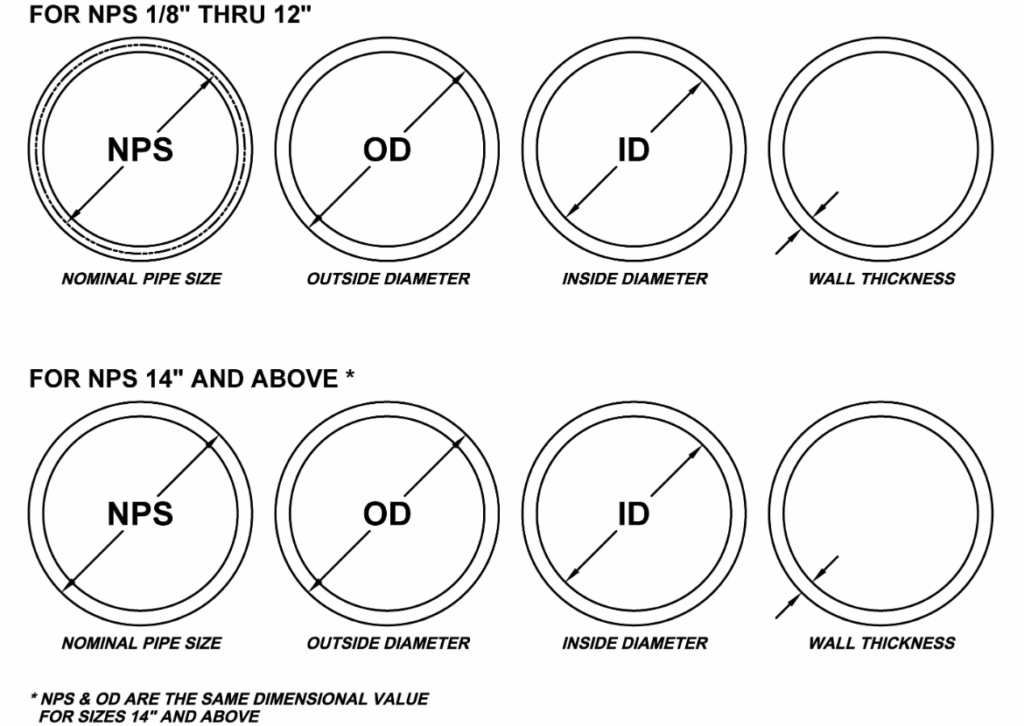

Dimensions

- EL —— Elevation

- BOP —— Bottom of pipe

- COP —— Center of pipe

- TOP —— Top of pipe

- FOB —— Flat on bottom

- FOT —— Flat on top

- CL —— Center line

- TL —— Tangent line

- SYM —— Symmetrical

- BOS —— Bottom of support

- TOS —— Top of support

- CL —— Clearance

- CTC —— Center to center

- CTF —— Center to face

- CTE —— Center to end

- ETE —— End to end

- FEF —— Flange and face

- FTF —— Face to face

- D —— Diameter

- DN —— Nominal diameter

- ID —— Inside diameter

- OD —— Outside diameter

- DIM —— Dimension

- MAX —— Maximum

- MIN —— Minimum

- AVG —— Average

- PT.EL —— Point elevation

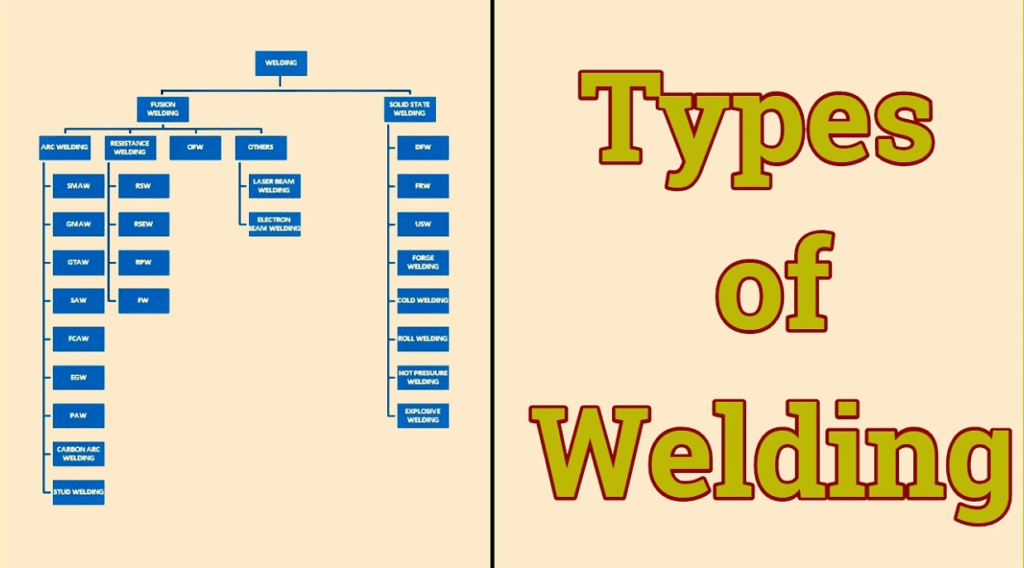

construction

- W —— Welding

- AW —— Arc welding

- GSAW —— Gas shielded-acr welding

- EFW —— Elecric fusion welding

- ERW —— Electric Resistance welding

- GW —— Gas welding

- LW —— Lap welding

- BW —— Butt welding

- TW —— Tack welding

- SW —— Socket welding

- CW —— Continuous welding

- SEW —— Seal welding

- SFG —— Surfacing

- FW —— Field welding

- HT —— Heat treatment

- PH —— Preheating

- SR —— Stress relief

- PWHT —— Post weld heat treatment

- EIT —— Examination, inspection & testing

- VE —— Visual examination

- UI (UT) —— Ultrasonic inspection (test)

- RI (RT) —— Radiographic inspection (test)

- MPI (MT) —— Magnetic particle inspection (test)

- LPI (PT) —— Liquid penterant inspection

- HADT —— Hardness testing

- HYDT —— Hydraulic testing

- PNET —— Pneumatic testing

- CE —— Covered electrode

- WW —— Welding wire

- ASSY —— Assembly

- F —— Field

- F/F —— Field faricated

- SF —— Suit in field

- CSP —— Cold spring

- BCT —— Bolt cold tightening

- BHY —— Bolt hot tightening

- CO —— Clean out

- ANNY —— Annealed

- PE —— Plain end

- BE —— Belelled end

- THR —— Thread

- HB —— Brinnel hardness

Summarize

We’ve explained the meanings of English abbreviations in various contexts above. Understanding their significance can help you achieve better construction results.

As a professional pipe manufacturer in China, Metleader possesses highly specialized technologies and solutions, offering one-on-one technical support tailored to your needs. If you’re interested in purchasing pipe fittings and steel pipes, please contact us.