Flange lap joint basics: classification, connection form and application

Contents

- Introduction

- What is a lap joint flange?

- Classification of lap joint flanges

- Flange connection types

- Lap joint flange installation steps

- Lap joint flange specifications

- Butt weld flange vs lap joint flange

- Applications of lap joint flanges

- Summary

Introduction

Among all the flange products we manufacture, lap joint flanges are a particularly popular type for pipes and piping systems.

A detailed understanding of their functions, classifications, and installation can ensure safer and more reliable equipment operation, reduce maintenance costs, and increase profitability.

In this article, we provide an in-depth explanation of the working principles, specifications, and differences between lap joint flanges and butt-weld flanges, helping you better select the right flange for your project.

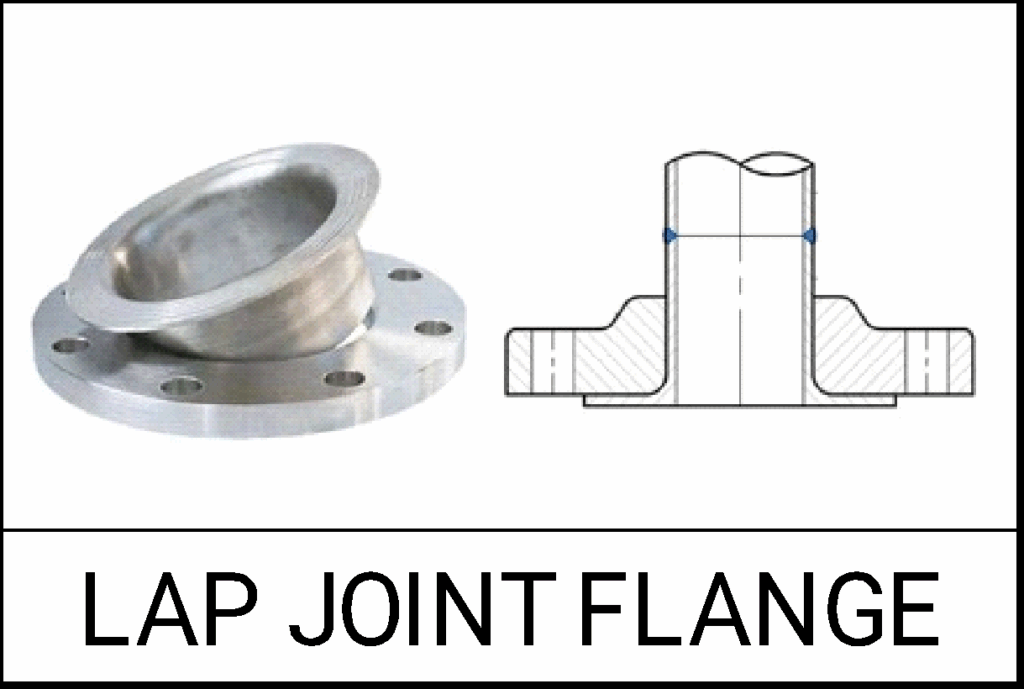

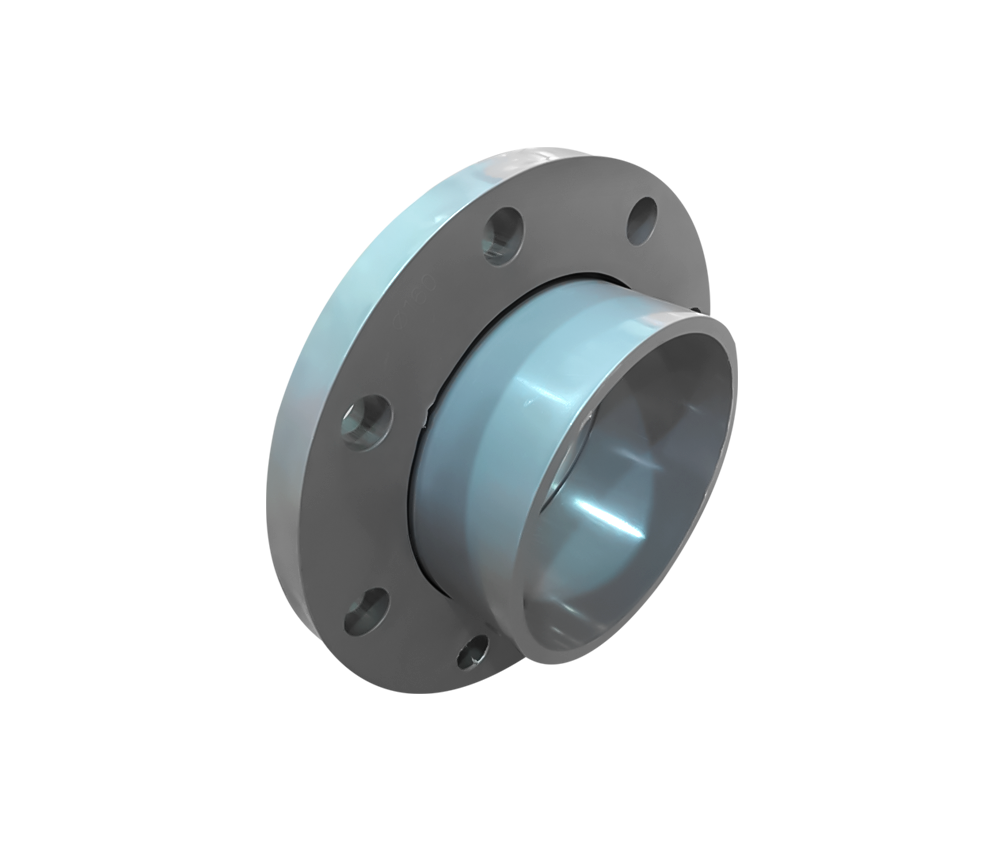

What is a lap joint flange?

Lap flange is one of the commonly used connection methods in pipeline systems, which refers to the method of tightening by cross-lapping the connecting surfaces of two flanges.

Classification of lap joint flanges

Lap joint flanges can be categorized by structure as follows:

Slip-on flange: The inner ring has a uniform surface and the connecting threads are very tight to the flange, preventing leaks.

Tee slip-on flange: This flange is used for tee pipes and has an extended intermediate member between the inner and outer rings.

Slip-on flange with retaining nut: This design is more practical and easier to use.

Double lap flange: This design uses two flanges, each with a lap ring on the outer side.

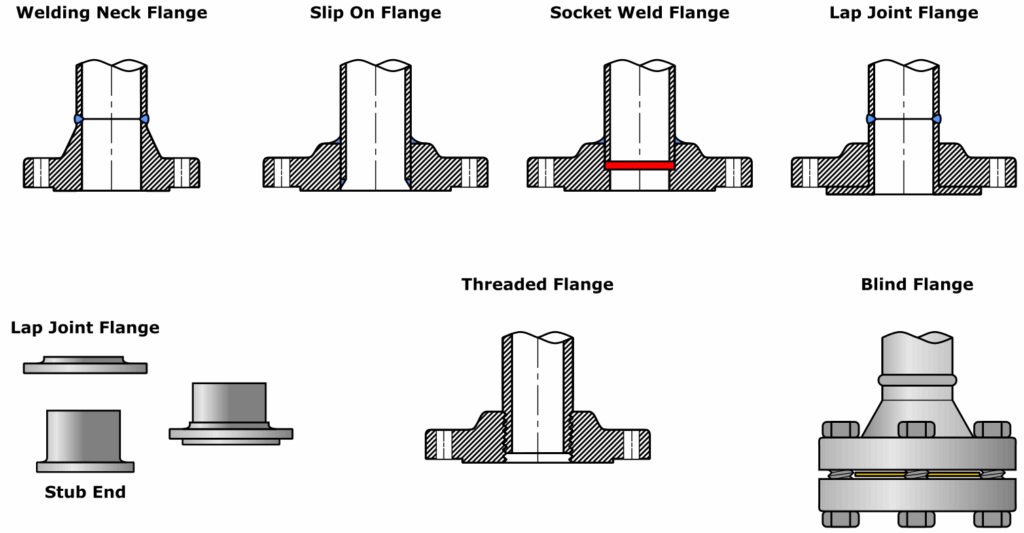

Flange connection types

Blind Flange Butt Welding

Blind flange butt welding is the simplest flange butt welding method. It is suitable for applications where pipes or equipment need to be sealed and periodically opened for maintenance.

Butt-Weld Flange Butt Welding

Butt-Weld Flange Butt Welding is a welding method. Its advantages include a tight connection without leakage, making it suitable for applications with high connection quality requirements.

Bolted Flange Butt Welding

Bolted flange butt welding is the most common flange butt welding method. It is characterized by its ease of connection and adaptability to various pipe and equipment connections.

Flange with Gasket Butt Welding

Flange with Gasket Butt Welding is a connection method that uses flanges and gaskets. It is suitable for applications with certain contact surfaces and connection quality requirements.

Lap joint flange installation steps

Install the lap flanges at each end of the pipe to be connected, ensuring they are coaxial with the pipe.

Insert a suitable gasket between the flanges to improve the sealing performance of the connection.

Thread the bolts through the bolt holes in the flanges and tighten the nuts until the two flanges fit tightly together. Be sure to tighten the bolts in a diagonal order to ensure even force is applied to the flanges.

Check the flange connection for a secure fit. Once confirmed to be free of looseness, the flange can be put into operation.

Lap joint flange specifications

The designation for a lap joint flange typically consists of four parts: the standard system, type designation, dimensional parameters, and pressure rating. For example, DN50 PN16″ indicates a lap joint flange with a nominal diameter of 50 mm and a pressure rating of 16 bar.

Key Parameters:

- Type designation: LJ is a common abbreviation for lap joint flanges; some standards may use other letter combinations.

- Dimensional parameters: Nominal diameter (DN) or inches (NPS), such as DN100 or 4″.

- Pressure rating: American Standard uses Class (e.g., 150/300/600).

Butt weld flange vS lap joint flange

| Feature | Butt Weld Flange (WN) | Lap Joint Flange (LJF) |

| Connection Type | Welded directly to pipe (full penetration) | Uses stub end + backing flange (non-welded) |

| Contact Surface | Pipe welds to flange hub | Pipe welds to stub end only |

| Pressure Containment | Flange maintains pressure | Stub end contains pressure |

| Rotational Capability | Fixed orientation | 360° rotation possible |

| Parameter | Butt Weld Flange | Lap Joint Flange |

| Pressure Rating | Full ASME Class rating (150-2500) | Limited to Class 150-300 |

| Corrosion Resistance | Dependent on flange material | Stub end determines corrosion resistance |

| Installation Cost | Higher (requires precise welding) | Lower (no alignment issues) |

| Maintenance | Difficult (requires cutting) | Easy (bolt-off replacement) |

| Typical Use | High-pressure/temperature systems | Low-pressure systems, frequent dismantling |

Applications of lap joint flanges

In some piping systems with large spans and heavy weights, lap flanges are often used to replace other connection methods.

Lap flanges are suitable for temperatures below/equal to 300 degrees Celsius and pressures below 16 MPa.

They are suitable for water, steam, air, oil, gas and other non-corrosive media.

Summary

Through this detailed introduction, we believe we’ve gained a deeper understanding of lap joint flanges.

As with any flange product, they aren’t universally applicable, and selection must be tailored to the project’s technical requirements.

Lap joint flanges are widely used in industries such as power generation, oil and gas, chemicals, and pharmaceuticals.

We hope this article will help you make a more informed choice.

If you’d like to learn more about flanges and pipe fittings, subscribe to our YouTube channel and LinkedIn for a comprehensive overview of Metleader.