SCH40S VS SCH80S in stainless steel pipes: a comprehensive explanation

Contents

- Introduction

- What is the wall thickness of SCH40S?

- What is the wall thickness of SCH80S?

- SCH Description in Pipe Fittings

- Calculation Methods and Standards for Pipe Wall Thickness

- Stainless Steel Pipe Wall Thickness Grade Classification

- SCH40S vs SCH40

- How to Choose the Appropriate Specification

- Summary

Introduction

When selecting and using pipes, we often see the SCH designation. This is very common in the steel pipe industry, as it serves as an abbreviation for a specific meaning and is a common notation used by engineers. Do you know what they mean?

This article explains the meaning of SCH40S and SCH80S, and also details the pipe wall thickness classifications and applicable specifications. We hope to help customers better select the appropriate steel pipe for their projects.

For more information and videos about steel pipes, please follow us on YouTube and LinkedIn.

What is the wall thickness of SCH40S?

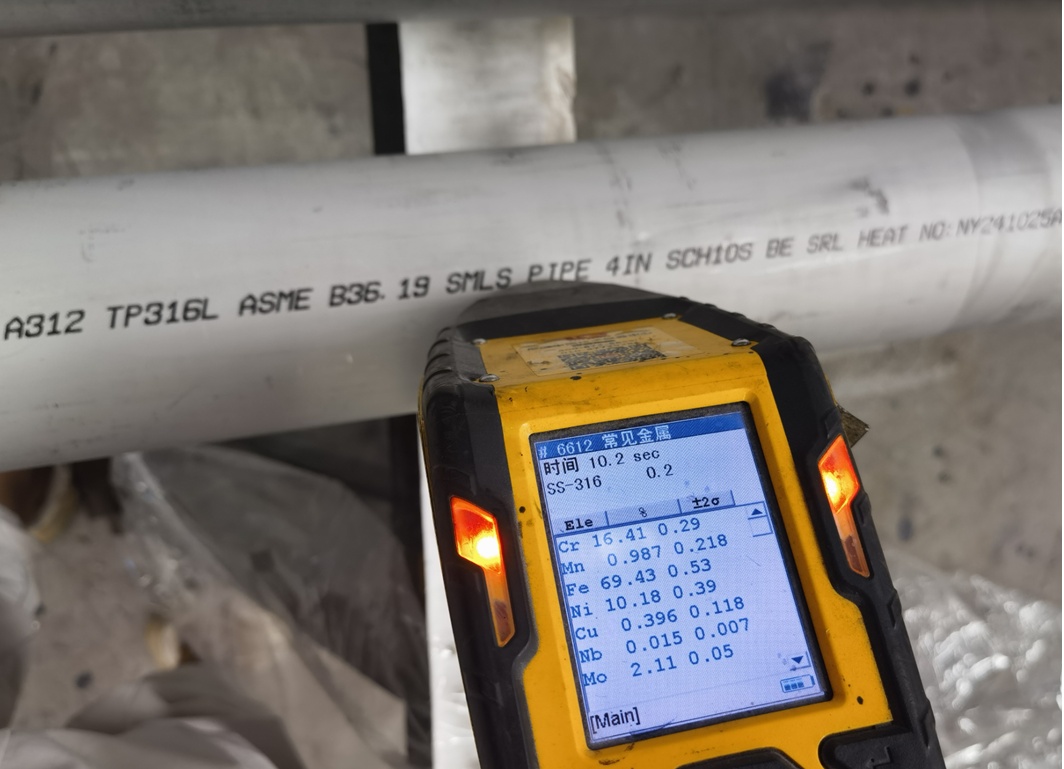

SCH40S is one of the common pressure grades of stainless steel pipes, and its wall thickness needs to be determined in conjunction with NPS. According to ASTM A312/A999:

The wall thickness of SCH40S changes with the pipe diameter, for example:

- NPS 1/2″ (DN15): wall thickness 2.77mm

- NPS 2″ (DN50): Wall thickness 3.91mm

- NPS 8″ (DN200): wall thickness 8.18mm

What is the wall thickness of SCH80S?

Sch80s, where the “S” refers to stainless steel pipes. The specific pipe wall thickness varies with the pipe’s outer diameter and is not a fixed value.

SCH Description in Pipe Fittings

SCH, short for Schedule, is commonly used in the pipe fitting industry to indicate pipe wall thickness grades.

It’s a standardized notation that allows designers, engineers, and construction personnel to accurately and quickly identify and select the required wall thickness when purchasing, designing, and installing pipe fittings.

Relationship between SCH and Wall Thickness

The numbers following SCH represent different wall thickness grades. These numbers correspond to specific wall thickness values.

Generally speaking, the larger the number, the thicker the wall thickness of the pipe fitting, and the greater its ability to withstand pressure.

Applications of SCH

SCH, as a method for identifying pipe wall thickness, is widely used in various types of pipe fittings, including steel pipes, stainless steel pipes, plastic pipes, etc.

In practical applications, it is very important to select the appropriate SCH grade according to different usage scenarios and requirements.

Calculation Methods and Standards for Pipe Wall Thickness

Calculating pipe wall thickness involves multiple factors, including the strength of the pipe material, design pressure, temperature, and pipe diameter.

American National Standards ANSI B36.10 and ANSI B36.19 detail the wall thicknesses for different pipe sizes and schedules.

These standards must be considered when designing or selecting pipes to ensure safety and efficiency.

The formula “pipe wall thickness = (outer diameter – inner diameter) / 2” is often used, but the most accurate wall thickness calculation should be performed by a professional engineer, referring to relevant standards.

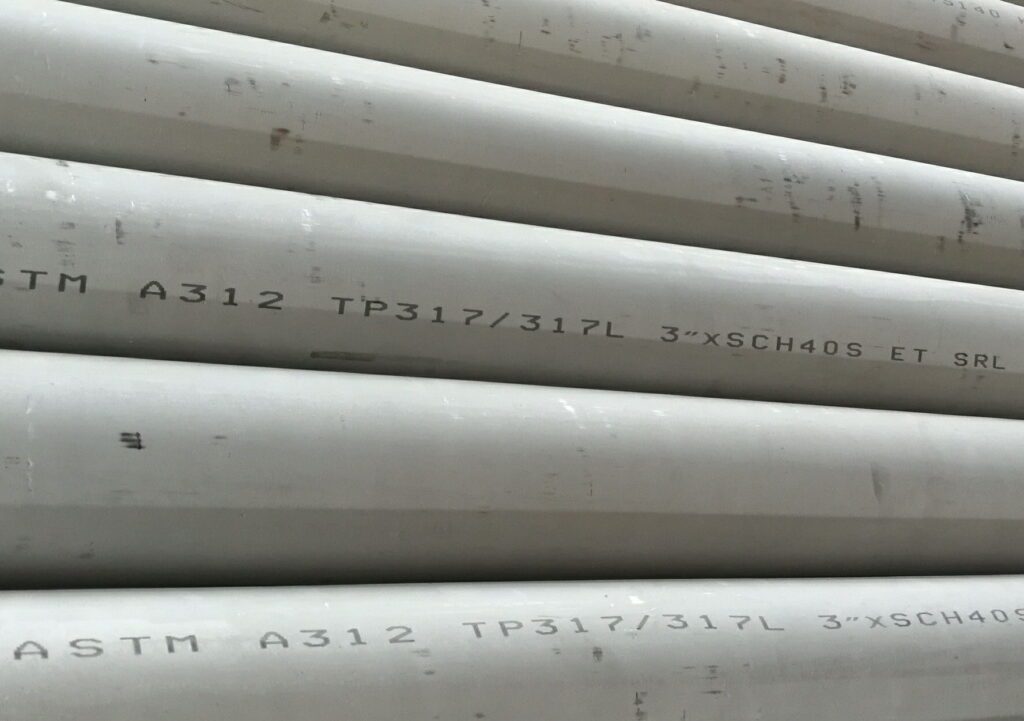

Stainless Steel Pipe Wall Thickness Grade Classification

Stainless steel pipe wall thickness grades are typically based on the ratio of pipe diameter to wall thickness.

Currently, the commonly used stainless steel pipe wall thickness grades are SCH5S, SCH10S, SCH40, SCH40S, SCH80S, SCH160, and XXS (thick-wall).

SCH5S represents stainless steel pipe with a wall thickness of approximately 0.6mm, while XXS represents stainless steel pipe with a wall thickness of approximately 9.5mm.

SCH40S vS SCH40

| Feature | SCH40S | SCH40 |

| Primary Material | Stainless Steel (ASTM A312) | Carbon Steel (ASTM A106/A53) |

| Wall Thickness | Thinner wall for given NPS | Standard wall thickness |

| Corrosion Allowance | Not required | Typically 0.125″ (3.2mm) included |

| Main Application | Corrosive service environments | General purpose, high-pressure systems |

| Parameter | SCH40S | SCH40 |

| Pressure Rating | Lower due to thinner walls | Higher pressure capability |

| Temperature Limit | Better high-temperature performance | Standard temperature range |

| Cost Comparison | Higher cost (stainless material) | More economical |

| Availability | Limited size range | Widely available in full size range |

| Fabrication | Requires special welding procedures | Standard welding methods applicable |

How to Choose the Appropriate Specification

The choice between SCH40S and SCH40 depends primarily on the application environment.

For applications requiring corrosion protection, such as food and chemical industries, SCH40S is the ideal choice; however, for general plumbing and building structures, SCH40 is sufficient.

Summary

I believe that through the above introduction, we have a clearer understanding of SCH and a deeper understanding of steel pipe designations.

As one of China’s most professional steel pipe manufacturers, Metleader provides high-quality steel pipe products to partners around the world. We welcome inquiries for pricing information.