ASTM A269 and ASTM A312 Seamless Steel Pipe: Differences and Applications

Table of contents

- Introduction

- What is ASTM A269?

- ASTM A269 Standard Tolerance Classification

- What is ASTM A312?

- Relationship between A312 and 304 Stainless Steel

- Chemical Composition Differences between ASTM A312 TP316 and TP316L

- ASTM Stainless Steel Pipe Standard System

- ASTM A269 vs ASTM A312

- Summary

Introduction

In the world of stainless steel piping, ASTM A269 and ASTM A312 are often mentioned, but what exactly are the differences between them?

This article will delve deeper into the differences between these two key specifications and explore their relationship to other types of steel pipe.

For more information on steel pipe, follow us on YouTube and LinkedIn.

What is ASTM A269?

ASTM A269 is a standard published by the American Society for Testing and Materials (ASTM).

It primarily addresses the manufacturing and tolerance requirements for seamless and welded austenitic stainless steel pipe.

This standard specifies the tolerances that stainless steel pipes of varying sizes and wall thicknesses must meet during manufacturing to ensure product quality and interchangeability.

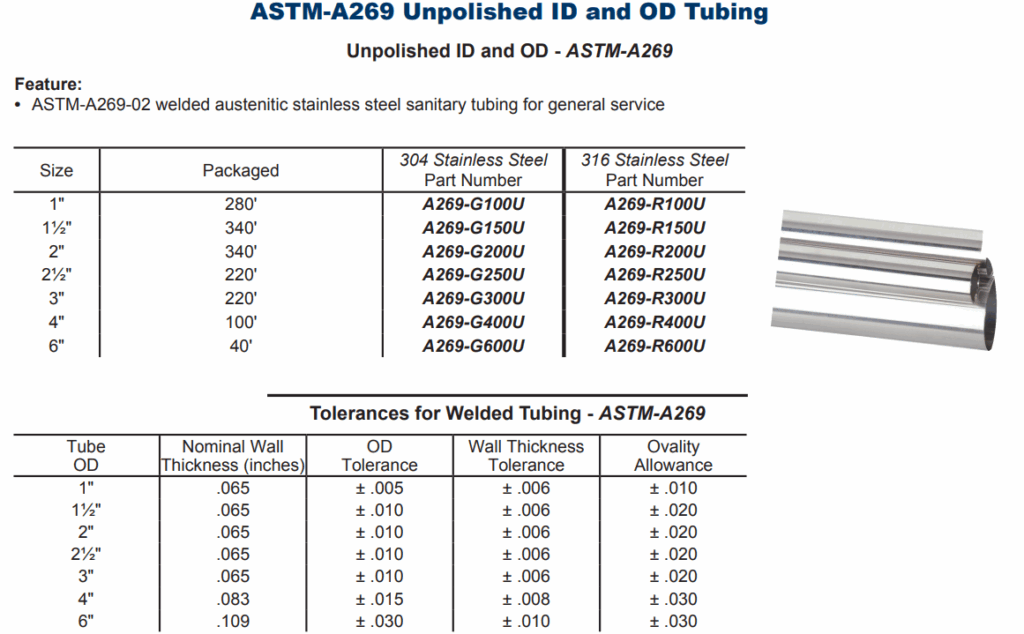

ASTM A269 Standard Tolerance Classification

According to ASTM A269, tolerances are primarily categorized as follows:

Dimensional tolerances: These include tolerances on the outside diameter, inside diameter, and wall thickness.

The specific values of these tolerances depend on the size range and manufacturing method of the stainless steel pipe.

Form tolerances: These primarily address the roundness, straightness, and curvature of the stainless steel pipe.

Properly setting these tolerances helps maintain the geometric shape and surface quality of the stainless steel pipe, thereby enhancing its service life and reliability.

What is ASTM A312?

ASTM A312 pipe is a seamless austenitic stainless steel pipe manufactured according to ASTM standards.

A312 pipe is primarily made of austenitic stainless steel, with a chemical composition primarily consisting of iron, chromium, and nickel.

The chromium content is generally above 18%, and the nickel content is above 8%.

This chemical composition gives A312 pipe excellent corrosion resistance, particularly in corrosive media such as oxidizing and organic acids.

Relationship between A312 and 304 Stainless Steel

Chemical Composition: A312 stainless steel and 304 stainless steel differ in their chemical composition.

304 stainless steel contains 18% chromium and 8% nickel.

The chemical composition of A312 stainless steel varies depending on the manufacturer and standard, and it often also contains elements such as chromium and nickel, but the proportions may differ from those of 304.

Physical Properties: A312 stainless steel and 304 stainless steel differ in properties such as tensile strength, yield strength, and elongation.

Applications: 304 stainless steel offers excellent corrosion resistance and good processability, making it widely used in construction, home furnishings, and kitchenware.

A312 stainless steel is used in specific industrial or residential applications based on its specific chemical composition and physical properties.

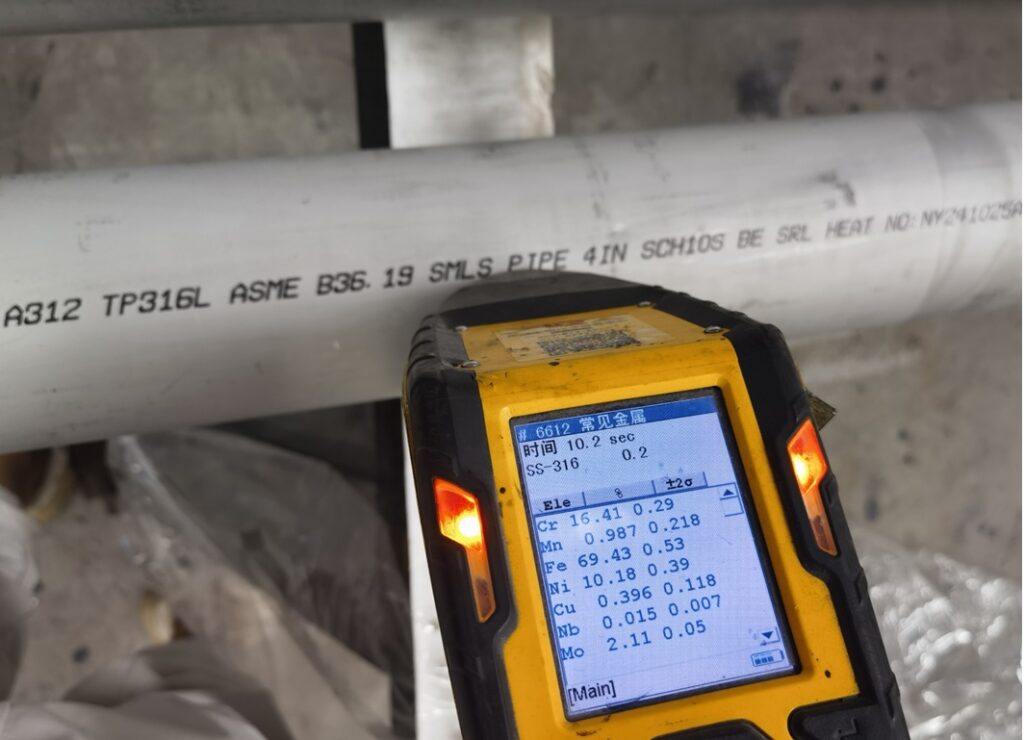

Chemical Composition Differences between ASTM A312 TP316 and TP316L

| Element | TP 316 | TP 316L |

| C | 0.08 max | 0.035 max |

| Mn | 2.00 max | 2.00 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| Si | 1.00 max | 1.00 max |

| Cr | 16.00-18.00 | 16.00-18.00 |

| Ni | 10.00-14.00 | 10.00-14.00 |

| Mo | 2.00-3.00 | 2.00-3.00 |

As can be seen from the chemical composition table above, the main difference in the chemical composition of ASTM A312 TP316 and 316L is the carbon content.

316L stainless steel is a low-carbon version of 316 stainless steel. The lower carbon content in 316L stainless steel can reduce harmful carbide precipitation caused by welding.

ASTM Stainless Steel Pipe Standard System

ASTM (American Standard) stainless steel pipe standards are primarily developed by ASTM. The following are commonly used standards and their characteristics:

ASTM A312: The most widely used standard for seamless welded austenitic stainless steel pipe, covering common grades such as 304 and 316. Suitable for conveying fluids in high-temperature, corrosive environments.

ASTM A269: The standard for general-purpose seamless and welded stainless steel pipe, commonly used in applications requiring high cleanliness, such as medical devices and food processing.

ASTM A790: Designed specifically for duplex stainless steel, it emphasizes high strength and chloride corrosion resistance and is suitable for marine applications.

ASTM A269 vS ASTM A312

| Feature | ASTM A269 | ASTM A312 |

| Primary Application | General service corrosion-resistant | High-temperature/pressure service |

| Size Range | 1/8″ to 3″ OD | 1/8″ to 24″ NPS |

| Wall Thickness | Light wall (schedule 5S/10S) | Standard wall (schedule 40/80) |

| Common Grades | TP304/304L, TP316/316L | TP304H, TP316H, TP321H |

| Parameter | ASTM A269 | ASTM A312 |

| Heat Treatment | Solution annealed minimum 1900°F | Solution annealed + quenched |

| Pressure Rating | Limited to moderate pressures | Full ASME B36.19 pressure rating |

| Testing | Hydrostatic or nondestructive | Mandatory hydrostatic test |

| Certification | Mill test report optional | Certified mill test report required |

Summary

Through our detailed introduction to the ASTM A269 and ASTM A312 standards above, we believe you’ve gained a deeper understanding of them.

When purchasing steel pipe, it’s important to distinguish the differences between the two and make your selection based on the project’s technical requirements.

As one of China’s most powerful steel pipe manufacturers, Metleader can tailor steel pipe products to customer requirements and provide complete steel pipe solutions, helping customers quickly implement projects and complete procurement tasks.