What are NPS and SCH?

Contents

- Preface

- What does NPS mean?

- NPS, DN, and OD

- The meaning of SCH for pipe fittings

- Usage of SCH and NPS

- Selection of SCH grade

- Summary

Preface

In piping engineering, NPS and SCH are two important parameters for pipe fittings, representing the nominal size and wall thickness rating of the fitting, respectively. These two parameters are crucial for ensuring the safe and efficient operation of the piping system.

Understanding their differences and meanings can help us better select suitable steel pipe fittings. This article provides a detailed explanation of NPS and SCH.

If you would like to learn more about Metleader’s production processes, please follow us on YouTube and LinkedIn.

What does NPS mean?

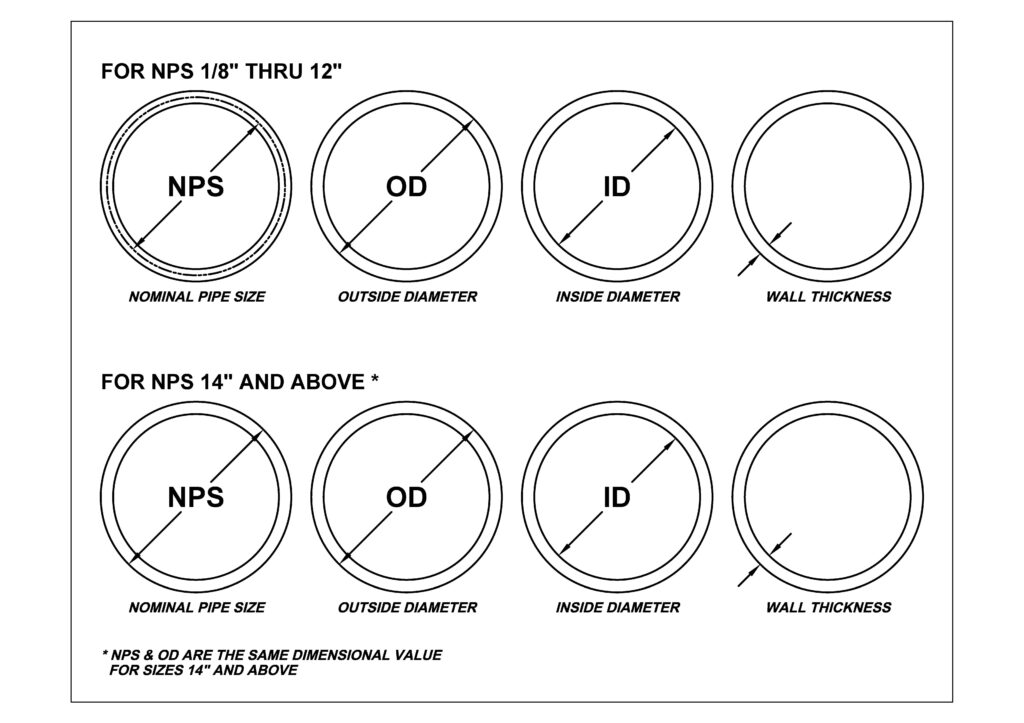

NPS is a pipe size standard used in North America, covering pipe sizes for high and low pressure applications and at various temperatures.

Its distinguishing feature is the use of two non-size designations to identify pipe dimensions: an NPS number in inches and a pipe gauge number, indicated by Sched. or Sch.

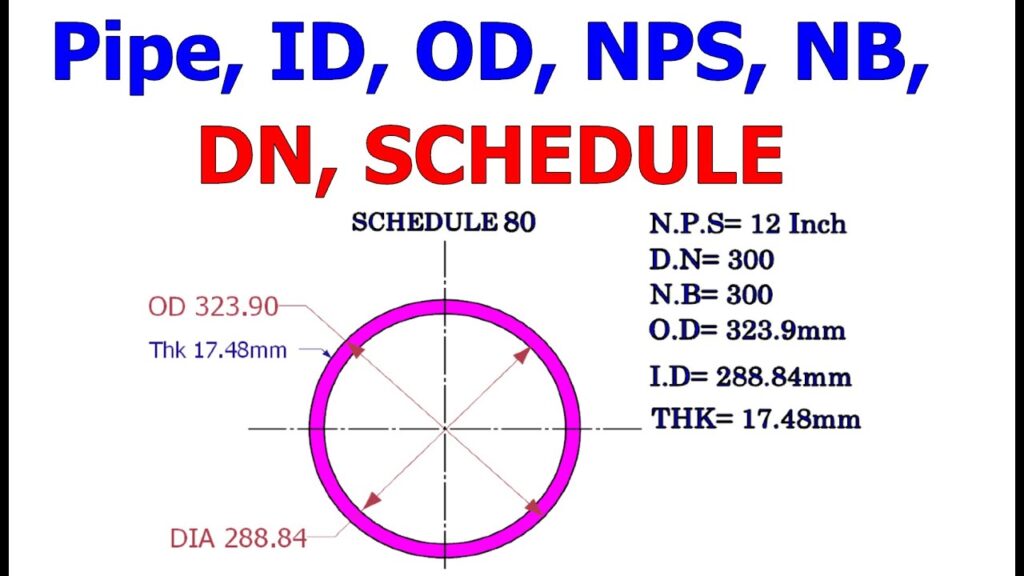

NPS, DN, and OD

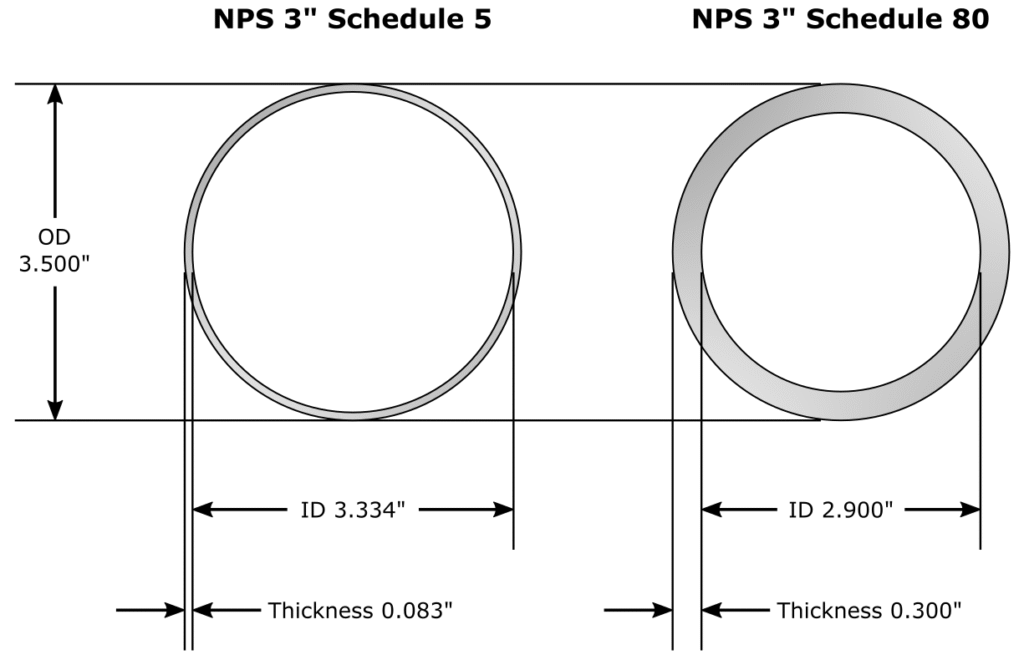

NPS: A method of representing nominal diameter. It is the North American standard system for pipe sizes, measured in inches. One inch is approximately equal to 25.4 mm. In ASME and API standards, the unit is inches.

DN: Another method of representing nominal diameter. It is a combination of letters and numbers used for piping systems, consisting of the letters DN followed by a dimensionless integer.

OD: The symbol for outer diameter is Φ, and it can be represented by OD. Steel pipes used for fluid transport worldwide are often divided into two series for outer diameter: Series A and Series B.

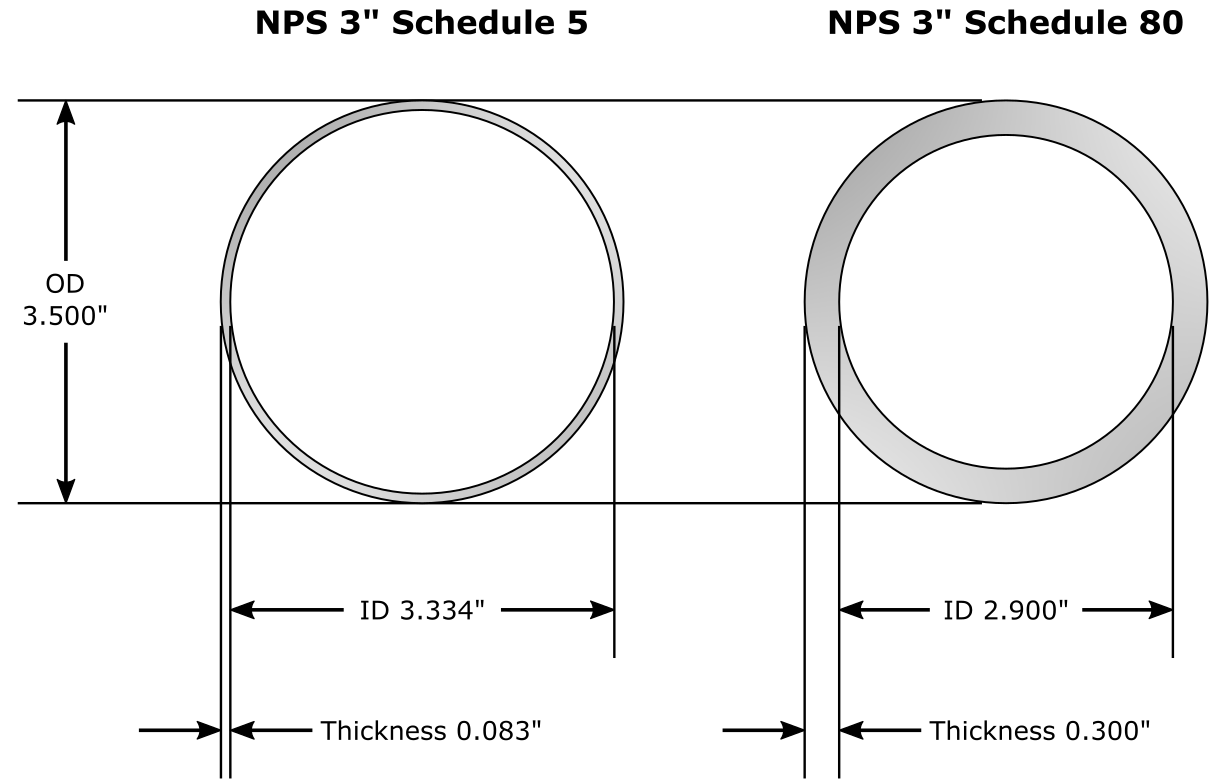

The meaning of SCH for pipe fittings

“SCH” is usually followed by a number, such as “SCH20,” which indicates the specific wall thickness rating.

Each wall thickness rating corresponds to a certain pipe wall thickness and pressure resistance.

For example, “SCH20” represents a specific wall thickness specification, which allows the pipe to withstand certain pressures and meet specific application scenarios.

In piping engineering, selecting the appropriate wall thickness rating is crucial to ensuring system safety and reliability.

Usage of SCH and NPS

The NPS (Number of Standard Dimensions) in pipe fitting designations primarily identifies the standardized diameter of the fitting, measured in inches.

While the NPS value doesn’t directly correspond to the actual outer diameter of the fitting, it provides a unified dimensional standard for piping engineering, facilitating international communication and standardized production.

In practical applications, NPS and SCH (Standard Diameter) typically work together to determine the fitting’s size and pressure resistance.

Choosing the appropriate combination of NPS and SCH ensures the safety and reliability of the piping system under specific operating conditions.

Selection of SCH grade

| Nominal Pipe Size (NPS) | SCH 5S | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 | SCH 120 | SCH 160 |

| 1/8″ | 1.24 | 1.73 | – | – | – | 2.41 | 3.02 | – | – |

| 1/4″ | 1.65 | 2.24 | – | – | – | 3.02 | 3.68 | – | – |

| 3/8″ | 1.65 | 2.31 | – | – | – | 3.20 | 4.01 | – | – |

| 1/2″ | 1.65 | 2.77 | 2.77 | – | – | 3.73 | 5.54 | – | 7.47 |

| 3/4″ | 1.65 | 2.87 | 2.87 | – | – | 3.91 | 5.56 | – | 7.82 |

| 1″ | 1.65 | 3.25 | 3.25 | – | – | 4.55 | 6.35 | – | 9.09 |

| 1 1/4″ | 1.65 | 3.25 | 3.25 | – | – | 4.85 | 6.35 | – | 9.70 |

| 1 1/2″ | 1.65 | 3.25 | 3.25 | – | – | 5.08 | 7.14 | – | 10.15 |

| 2″ | 1.65 | 3.05 | 3.05 | – | – | 5.54 | 8.74 | 11.07 | 12.70 |

| 2 1/2″ | 2.11 | 4.19 | 4.19 | – | – | 7.01 | 9.53 | 13.49 | 15.09 |

| 3″ | 2.11 | 4.32 | 4.32 | – | – | 6.55 | 8.89 | 11.13 | 15.24 |

| 4″ | 2.11 | 4.19 | 4.19 | 6.35 | 7.04 | 8.56 | 11.13 | 14.22 | 17.48 |

| 6″ | 2.11 | 4.19 | 4.19 | 6.35 | 7.80 | 10.97 | 14.73 | 19.05 | 21.95 |

| 8″ | 2.11 | 5.49 | 5.49 | 6.35 | 8.18 | 12.70 | 20.62 | 23.01 | 23.83 |

| 10″ | 2.77 | 5.84 | 5.84 | 6.35 | 9.09 | 15.09 | 22.23 | 25.40 | 28.58 |

| 12″ | 3.05 | 6.02 | 6.02 | 6.35 | 9.53 | 17.48 | 25.40 | 28.58 | 30.96 |

| 14″ | 3.05 | 6.35 | 6.35 | 7.92 | 9.53 | 19.05 | – | – | 33.32 |

| 16″ | 3.05 | 6.35 | 6.35 | 7.92 | 9.53 | 20.62 | – | – | 35.71 |

| 18″ | 3.05 | 6.35 | 6.35 | 7.92 | 11.10 | 22.23 | – | – | 38.10 |

| 20″ | 3.05 | 6.35 | 6.35 | 9.53 | 12.70 | 24.61 | – | – | 40.49 |

Summary

The dimensions of a steel pipe are determined by the following two dimensionless numbers:

- NPS size

- SCH serial number

The relationship between these two figures determines the inner diameter of the steel pipe.

Understanding the relationship between these two figures can help us better select the appropriate steel pipe. If you have any further questions, please contact Metleader engineers.

We not only provide high-quality steel pipe products globally but also offer project solutions to our clients. We look forward to your email.