Beginner’s Guide: An article to help you understand butt-welded pipe fittings

Contents

- Preface

- What are Butt-Welded Pipe Fittings?

- Manufacturing Standards for Butt-Welded Pipe Fittings

- Types of Butt-Welded Pipe Fittings

- Materials of Butt-Welded Pipe Fittings

- Applications of Butt-Welded Pipe Fittings

- Characteristics of Butt-Welded Connections

- Why Choose Metleader Butt-Welded Pipe Fittings?

Preface

Welded pipe fittings are a type of high-quality pipe fitting widely used in the construction industry. In recent years, the demand for welded pipe fittings has gradually increased, and the market has begun to recognize their advantages and performance.

Understanding the basics of welded pipe fittings can help us better select the right ones. This article will focus on the standards, types, materials, and characteristics of welded pipe fittings, hoping to be helpful to you.

If you would like to learn more about welded pipe fittings through videos, please follow us on YouTube and LinkedIn.

What are Butt-Welded Pipe Fittings?

Butt-welded pipe fittings are a common type of pipe fitting manufactured using welded pipes, which are directly welded to the pipes using a butt-welding method.

Manufacturing Standards for Butt-Welded Pipe Fittings

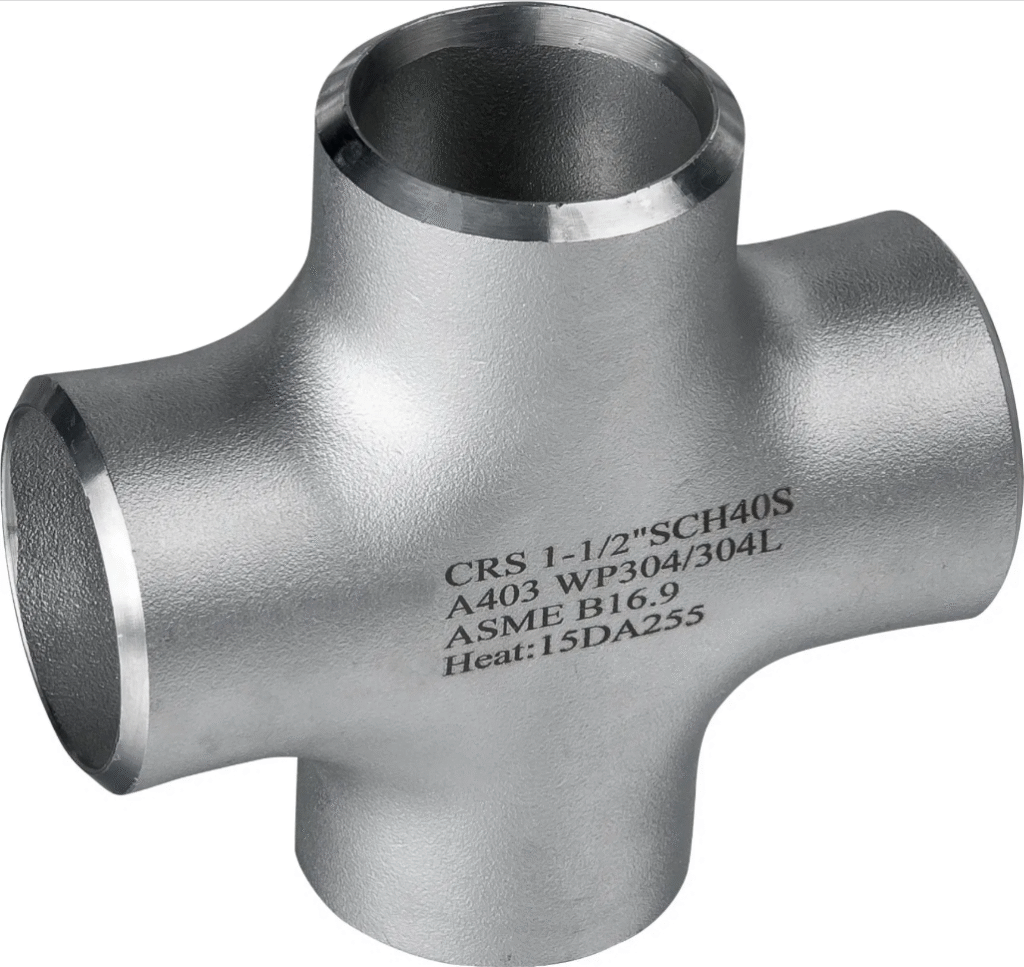

The production of butt-welded pipe fittings should comply with Chinese standards GB/T12459, GB/T13401 or industry standards ASME B16.9, JIS B2311/2312/2313, etc., among which GB/T12459 and ASME B16.9 are the main standards for butt-welded pipe fittings.

Types of Butt-Welded Pipe Fittings

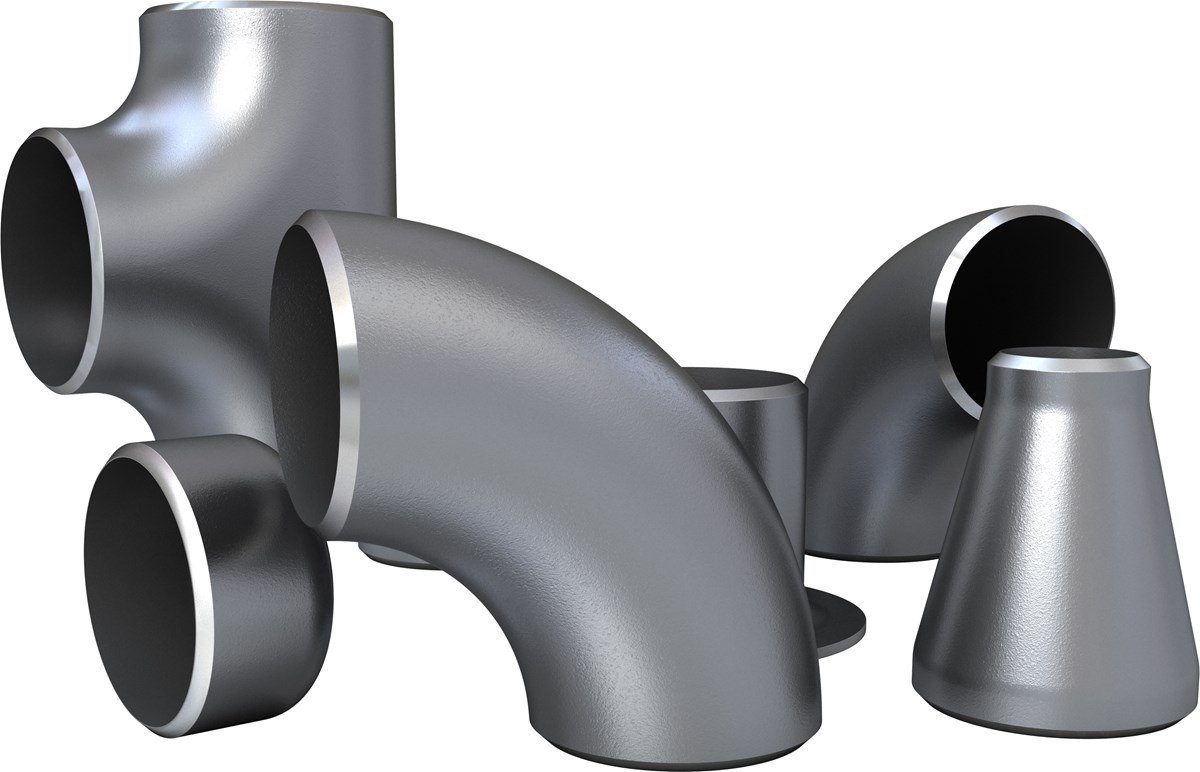

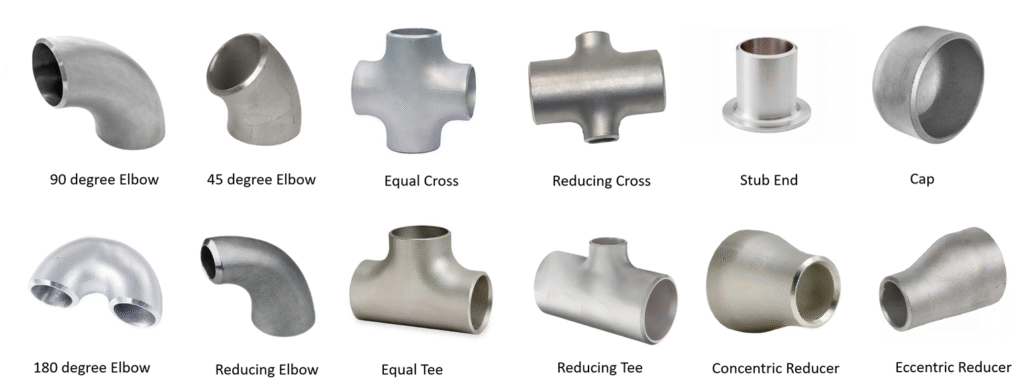

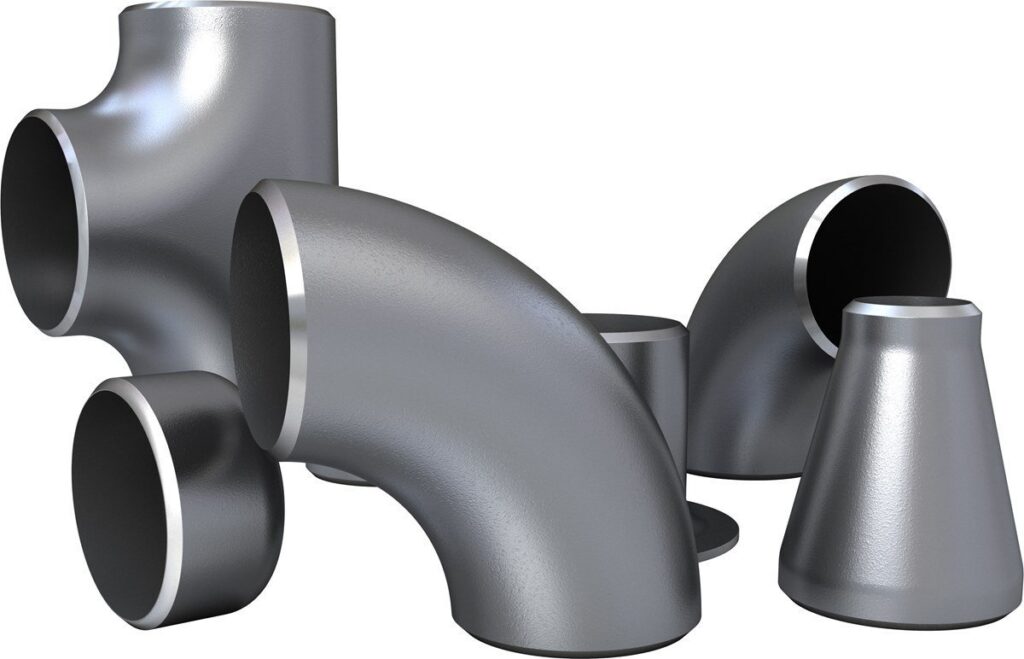

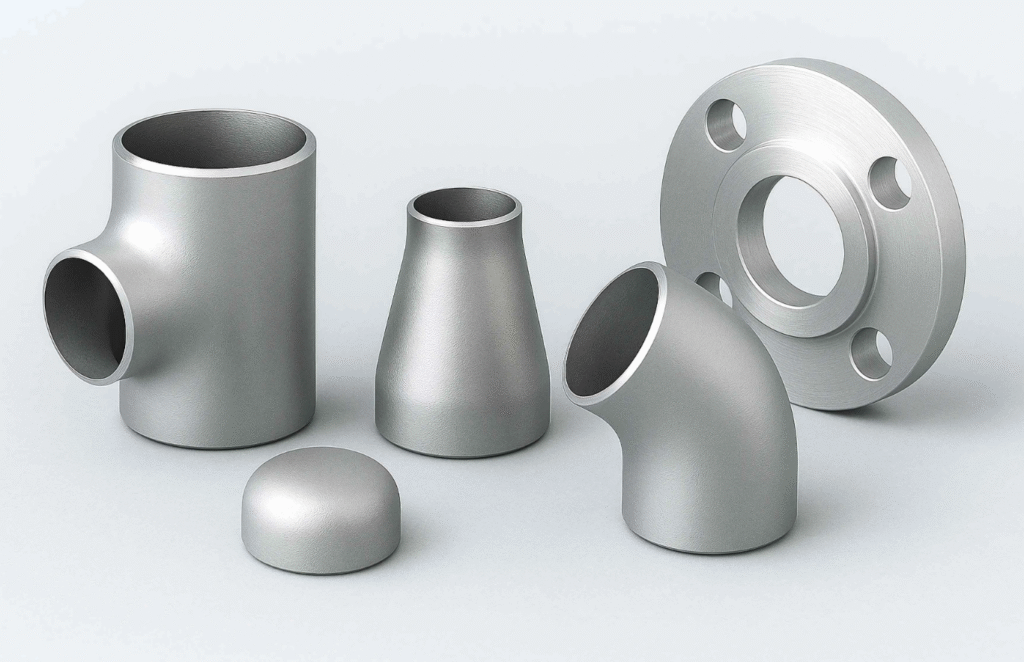

According to the connection method, butt-welded pipe fittings can be divided into butt-welded elbows, butt-welded tees, butt-welded crosses, butt-welded reducers, etc.

Butt-Welded Elbows

A butt-welded elbow is a standard pipe fitting used in piping systems to connect two pipe sections and change the direction of fluid flow. It is connected to the pipeline by butt welding.

Elbows are classified into long-radius elbows and short-radius elbows according to their size; and into push-formed elbows, extruded elbows, and welded mitered elbows according to their manufacturing method.

Butt-Welded Tees

Butt-welded tees are generally divided into equal diameter tees and reducing tees, and the materials include carbon steel, alloy steel and stainless steel.

Butt-Welded Reducers

A butt-welded reducer is a pipe fitting used to connect two pipes of different diameters. Its two ends have different diameters, one end being larger and the other smaller.

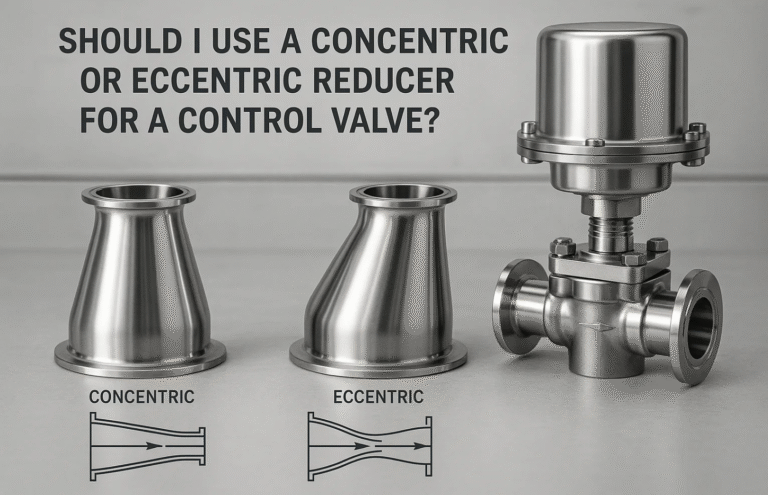

Structurally, butt-welded reducers are mainly divided into concentric reducers and eccentric reducers.

Materials of Butt-Welded Pipe Fittings

Butt-welded pipe fittings are generally made of carbon steel, stainless steel, alloy steel, and low-alloy steel, but the most common are carbon steel and stainless steel.

Carbon Steel Butt-Welded Pipe Fittings

Carbon steel butt-welded pipe fittings are pipe connection components manufactured using carbon steel. The product range includes large-diameter butt-welded pipe fittings, seamless butt-welded pipe fittings, and thick-walled elbows:

Large-diameter butt-welded pipe fittings: used for connecting main pipelines in transportation systems;

Seamless butt-welded pipe fittings: suitable for high-pressure or high-sealing applications;

Thick-walled elbows: including carbon steel butt-welded pipe fittings, seamless butt-welded pipe fittings, and thick-walled elbows.

Stainless Steel Butt-Welded Pipe Fittings

Stainless steel contains alloying elements such as chromium (Cr), nickel (Ni), and molybdenum (Mo), and has excellent corrosion resistance and high temperature resistance; it is often used in industrial pipelines in corrosive environments.

Applications of Butt-Welded Pipe Fittings

Butt-welded pipe fittings are widely used in many industrial fields, including petrochemicals, power, pharmaceuticals, and construction. In these industries, the stability and sealing of pipeline systems are crucial, so butt-welded pipe fittings have become indispensable connecting elements due to their superior performance.

Characteristics of Butt-Welded Connections

High strength: Butt-welded pipe fittings are connected to the pipeline by welding, forming a stable whole with high connection strength.

Good sealing performance: The welding method makes the connection between the fitting and the pipeline virtually seamless, ensuring excellent sealing performance.

Corrosion resistance: Depending on the operating environment and medium, butt-welded pipe fittings can be made of different materials to improve corrosion resistance.

Why Choose Metleader Butt-Welded Pipe Fittings?

As one of China’s largest manufacturers of weld neck pipe fittings, Metleader has been operating for 43 consecutive years, possessing extensive experience and advanced manufacturing processes.

Regarding our products, we source our raw materials from major domestic steel mills, conducting multiple tests in each round to ensure compliance with international standards.

We also support customization according to customer requirements, meeting needs in terms of size, pressure rating, and materials.

Many customers have strict time constraints on order delivery. We maintain ample inventory of standard weld neck pipe fittings to guarantee on-time delivery.

If you have any purchasing needs in this area, please contact us. Our sales consultants will provide free technical support and service.