Introduction to the basics of corrosion-resistant steel pipe: a beginner’s guide

Table of contents

- Preface

- What is an anti-corrosion steel pipe

- Classification of anti-corrosion steel pipe

- Specifications of anti-corrosion steel pipe

- Standards of anti-corrosion steel pipe

- Application of anti-corrosion steel pipe

- Anti-corrosion steel pipe VS galvanized steel pipe

- Anti-corrosion steel pipe VS insulated steel pipe

- Top ten anti-corrosion steel pipe manufacturers in China

- Summary

Preface

Anti-corrosion steel pipes are widely used in industry and light industry because of their excellent anti-corrosion performance.

Understanding the characteristics and standards of anti-corrosion steel pipes and the differences from other steel pipes will help us better choose steel pipes suitable for our projects;

Many large companies will also do a lot of preparation when choosing anti-corrosion steel pipes to understand the relevant performance and test results of seamless steel pipes.

Therefore, it is very important for beginners to understand the basic knowledge of anti-corrosion steel pipes.

This article focuses on the standard specifications and applications of anti-corrosion steel pipes and the differences from other steel pipes. I believe it will provide you with some help.

What is an anti-corrosion steel pipe

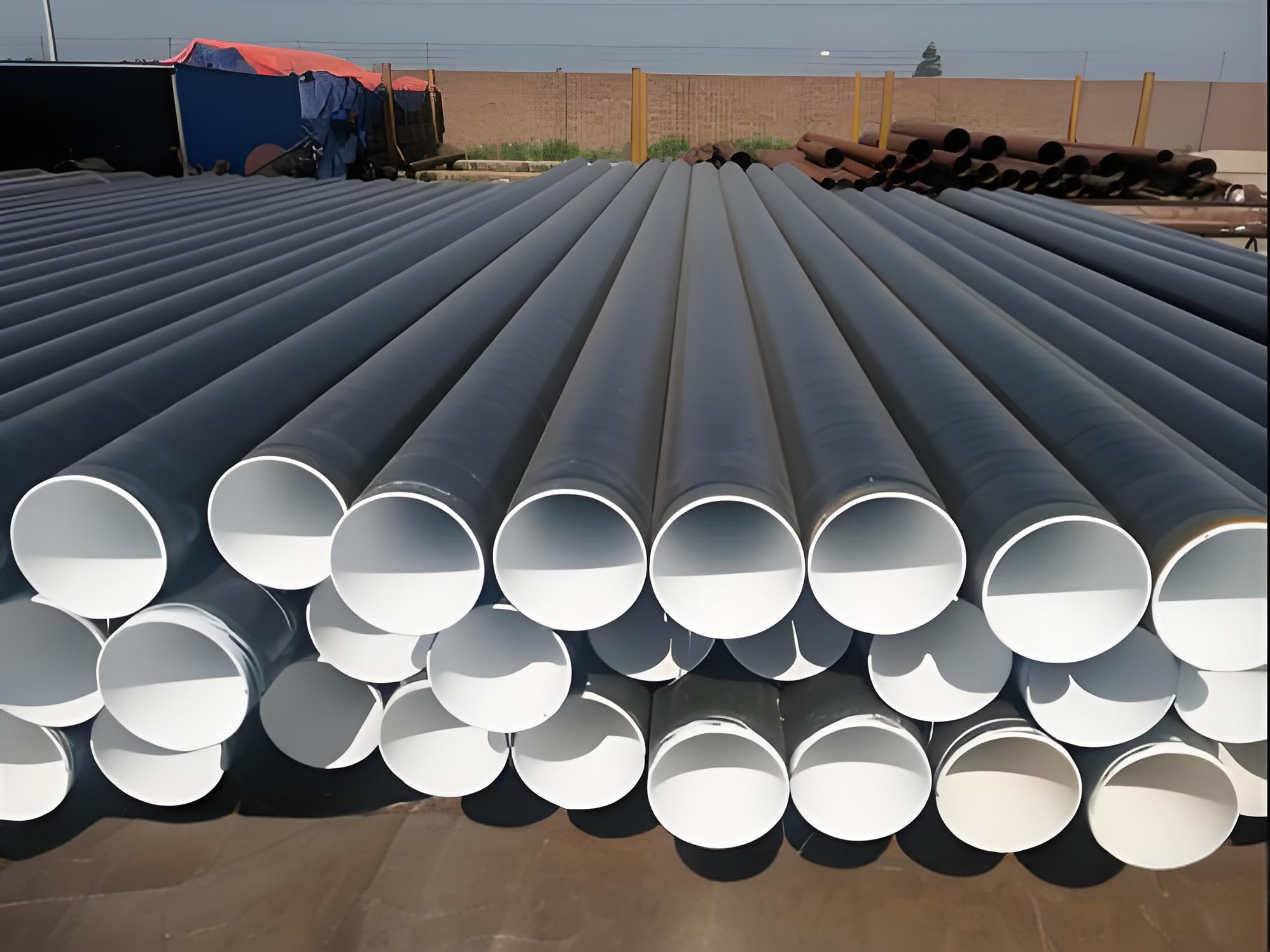

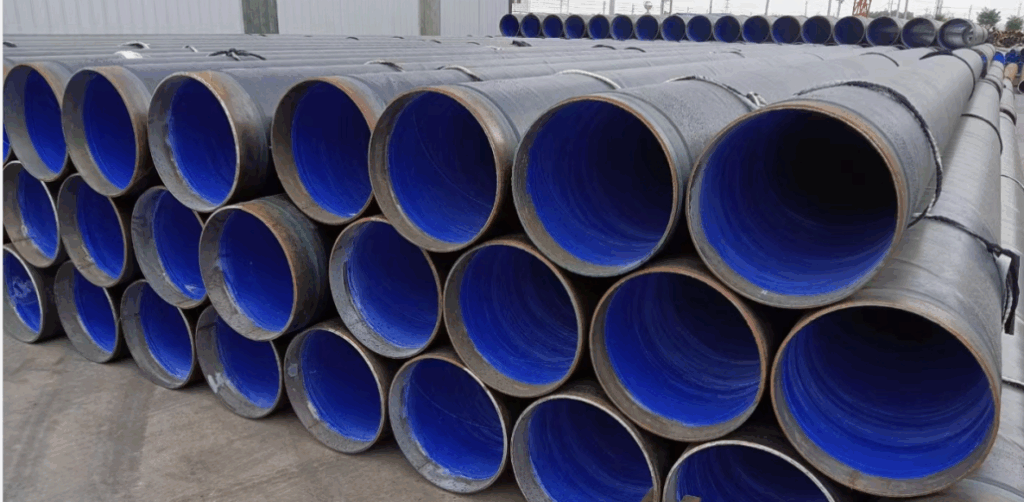

Anti-corrosion steel pipe refers to ordinary steel pipe that has been treated with anti-corrosion by coating, spraying or covering to improve its corrosion resistance in harsh environments.

Classification of anti-corrosion steel pipe

According to the anti-corrosion treatment method, anti-corrosion steel pipes can be mainly divided into the following categories:

Coated anti-corrosion steel pipe

By applying an anti-corrosion coating on the outer surface of the steel pipe, a protective film is formed to avoid direct contact with corrosive media.

Hot-dip galvanized steel pipe

Immersing the steel pipe in molten zinc creates a corrosion-resistant zinc layer, greatly improving its corrosion resistance.

Seamless anti-corrosion steel pipe

Anti-corrosion treatment is carried out on the basis of seamless steel pipe to ensure that the entire pipe body is evenly anti-corrosion.

Corrosion-resistant alloy steel pipe

By spraying corrosion-resistant alloy material on the surface of the steel pipe, a solid protective layer is formed to effectively resist various corrosive media.

Specifications of anti-corrosion steel pipe

Small-diameter anti-corrosion steel pipe

Outer diameter range: DN15~DN150 (corresponding to outer diameter Φ21.3mm~Φ168.3mm).

Application scenarios: indoor pipelines, small-flow water supply, gas branch pipes, etc.

Medium-diameter anti-corrosion steel pipe

Outer diameter range: DN200~DN600 (corresponding to outer diameter Φ219.1mm~Φ610mm).

Application scenarios: municipal water supply, sewage treatment, industrial pipelines, etc.

Large-diameter anti-corrosion steel pipe

Outer diameter range: DN700~DN2000+ (corresponding to outer diameter Φ711mm~Φ2032mm and above).

Application scenarios: long-distance oil and gas pipelines, large-scale water conservancy projects, submarine pipelines, etc.

The wall thickness of the anti-corrosion steel pipe needs to match the nominal pressure (PN) or the pipeline design pressure.

The common wall thickness range is as follows:

Low-pressure pipeline (PN≤1.6MPa): wall thickness 3~8mm (such as DN100~DN300 pipeline).

Medium-pressure pipeline (1.6MPa<PN≤10MPa): wall thickness 8~16mm (such as DN400~DN800 pipeline).

High-pressure pipeline (PN>10MPa): wall thickness 16~30mm+ (such as natural gas long-distance pipeline, chemical high-pressure pipeline).

Standards of anti-corrosion steel pipe

API 5L: American Petroleum Institute standard, which specifies the technical conditions for steel pipes used in the oil and gas industry, including anti-corrosion requirements.

ISO 21809: Standard issued by the International Organization for Standardization, mainly for external anti-corrosion coatings for oil and gas industry pipeline transportation systems. This standard covers many types of anti-corrosion coatings.

NACE RP0169: American Association of Corrosion Engineers standard, focusing on external corrosion control of pipeline systems.

Application of anti-corrosion steel pipe

Oil and gas transportation: Anti-corrosion steel pipes can resist the erosion of chemicals and ensure the long-term stable operation of pipelines.

Urban gas and water supply: Pipelines need to withstand the test of various environmental conditions, and anti-corrosion steel pipes can provide long-term protection.

Logistics and transportation: Anti-corrosion steel pipes can be used to transport various liquids and gases to ensure the safe and efficient transportation of goods.

Industrial application: Anti-corrosion steel pipes can be used in production lines in various chemical, pharmaceutical, food processing and other industries to ensure the smooth progress of the production process.

Environmental protection and water treatment: Anti-corrosion steel pipes are used in sewage treatment systems, rainwater collection systems, etc. to ensure the rational use of water resources and environmental protection.

Anti-corrosion steel pipe VS galvanized steel pipe

| Parameter | Anti-Corrosion Steel Pipe | Galvanized Steel Pipe |

| Primary Protection Method | External/internal coatings or linings (e.g., FBE, 3LPE, epoxy, PU). | Zinc coating applied via hot-dip/electro-galvanization. |

| Corrosion Mechanism | Barrier protection + supplementary cathodic protection. | Sacrificial/anodic protection (zinc corrodes first). |

| Coating Thickness | 300–3000 µm (varies by system, e.g., 3LPE: ≥1.8mm). | 50–200 µm (*per ASTM A123/A153*). |

| Temperature Resistance | High (FBE: ≤150°C; 3LPE: ≤80°C). | Limited (zinc degrades >60°C in moist environments). |

| Field Repair Feasibility | Complex (requires specialized equipment/materials). | Simple (zinc-rich paints/cold galvanizing). |

| Abrasion Resistance | Superior (polyethylene/urethane topcoats). | Moderate (soft zinc layer vulnerable to mechanical damage). |

| Chemical Resistance | Customizable (e.g., epoxy resists acids; PU resists solvents). | Weak against acids/alkalis (pH >12 or <6 accelerates corrosion). |

| Service Life | 30–50+ years (with CP system). | 15–25 years (dependent on environment). |

| Installation Impact | Coating damage during handling requires strict protocols. | Tolerant to minor handling damage (self-healing property). |

| Cost Factor | Higher initial cost, lower lifecycle cost. | Lower initial cost, higher maintenance long-term. |

| Key Standards | ISO 21809, CSA Z245.20/21, AWWA C210/C213. | ASTM A123, A153, ISO 1461. |

| Typical Applications | Subsea pipelines, oil/gas transmission, chemical plants. | Structural supports, water distribution, fencing. |

Anti-corrosion steel pipe VS insulated steel pipe

| Characteristic | Anti-Corrosion Steel Pipe | Insulated Steel Pipe |

| Primary Function | Prevent pipe degradation from chemical/electrochemical corrosion. | Minimize heat loss/gain in fluid transport systems. |

| Core Construction | Base pipe + corrosion-resistant coating/lining. | Triple-layer system: Carrier pipe + insulation + outer jacket. |

| Key Material Layers | • Steel substrate • Corrosion barrier (e.g., FBE, 3LPE, epoxy) | 1. Carrier Pipe: Carbon/stainless steel (often coated) 2. Insulation: PU foam, mineral wool, aerogel 3. Jacket: HDPE, steel, PVC |

| Critical Standards | ISO 21809, NACE RP0169, CSA Z245.20-18 | EN 253, EN 13941-1, ASTM C335 (insulation performance) |

| Thickness Focus | Coating thickness (200–3000 μm) | Insulation thickness (25–150 mm) |

| Temperature Range | Dictated by coating type (*e.g., FBE: -40°C to 150°C*) | Dictated by insulation (*PU: -196°C to 140°C*) |

| Installation Complexity | • Field joint coating critical • Requires CP system | • Trench geometry critical • Electrofusion for HDPE joints |

| Failure Mode | Coating disbondment/cathodic shielding | Insulation collapse/water ingress (“wet sock” syndrome) |

| Field Repairs | Specialized coating + holiday detection | Sleeve repair kits or sectional replacement |

| Typical Applications | • Subsea pipelines • Chemical processing lines • Water transmission | • District heating networks • Chilled water systems • Oil flowlines (viscosity maintenance) |

| Interface Integration | May include internal linings (cement mortar, epoxy) | Carrier pipe often pre-coated with FBE/3LPE for corrosion resistance |

| Hydrotest Protocol | Post-coating test at 90% SMYS | Post-installation test at 1.5x design pressure |

| Service Life Drivers | • Coating adhesion • CP system integrity | • Watertight jacket • Insulation thermal stability |

Top ten anti-corrosion steel pipe manufacturers in China

| Rank | Company Name | Location | Main Products |

| 1 | CNPC Bohai Equipment | Hebei Province | 3LPE/3LPP pipes, FBE-coated pipes, subsea pipelines |

| 2 | Jiangsu Sunpower Group | Jiangsu Province | Anti-corrosion spiral pipes, FBE pipes, thermal insulation pipes |

| 3 | Zhejiang Kingland Pipeline | Zhejiang Province | 3LPE pipes, cement mortar lined pipes, epoxy-coated pipes |

| 4 | Hebei Taihang Steel Pipe | Hebei Province | FBE pipes, IPN8710 water pipes, 3LPE gas pipelines |

| 5 | Tianjin Pipe Corporation (TPCO) | Tianjin | FBE/3LPE oil & gas pipes, sour service pipes (NACE MR0175) |

| 6 | Beijing Metleader Pipeline Technology Inc. | Beijing | Anti-Corrosion Steel Pipe,Insulated Steel Pipe, Galvanized Steel Pipe |

| 7 | Shandong Oriental Steel Pipe | Shandong Province | 3LPP/FBE pipes, concrete weight-coated pipes, internal epoxy lining |

| 8 | Jiangsu Changjiang Pipe | Jiangsu Province | Anti-corrosion ERW pipes, 3LPE pipes, CIPPS cement-lined pipes |

| 9 | Zhongmao Lining Technology | Hubei Province | PTFE/PFA-lined pipes, acid-resistant epoxy pipes, dual laminate pipes |

| 10 | Hengyang Valin Steel Tube | Hunan Province | FBE-coated pipes, 3LPE pipelines, thermal spray aluminum (TSA) coatings |

Summary

Anti-corrosion steel pipes have a wide range of applications and excellent corrosion resistance.

With the continuous advancement of technology and the continuous expansion of the market, anti-corrosion steel pipes will better meet the needs of various industries for pipeline systems and provide more reliable support for people’s production and life.

If you want to learn more about steel pipe fittings, you can follow our youtube and LinkedIn channels.