Carbon Steel Pipe Knowledge Explained: Buyer’s Guide

Table of contents

- Introduction

- What is carbon steel pipe

- Material classification of carbon steel pipe

- Application of carbon steel pipe

- Dimensions and weight of carbon steel pipe

- Standard basis of carbon steel pipe

- Carbon steel pipe VS black pipe

- Carbon steel pipe VS MS pipe

- Top ten carbon steel pipe manufacturers in Asia

- How to choose carbon steel pipe

- Summary

Introduction

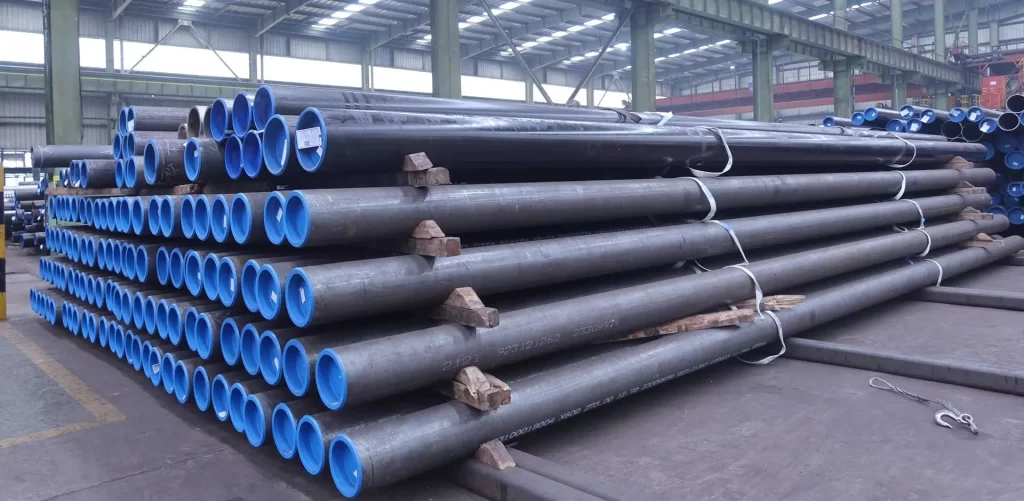

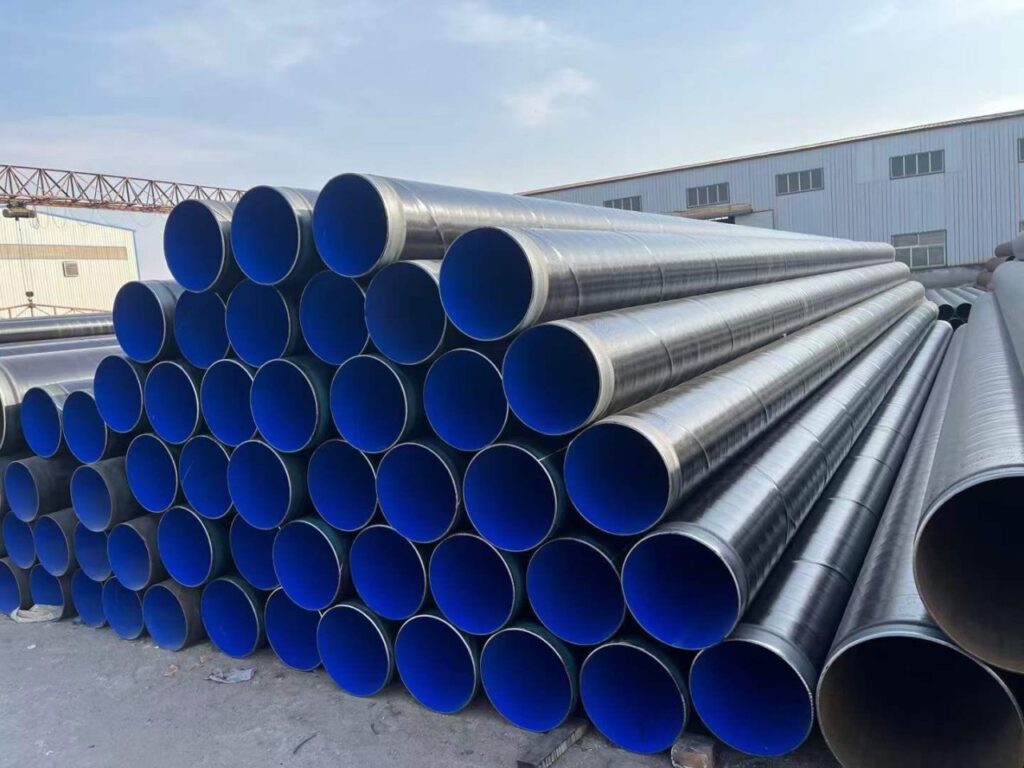

Carbon steel pipe is one of the most important basic materials in modern industry. Whether it is the transportation of oil and gas, or construction, machinery manufacturing, aerospace and other industries, carbon steel pipe plays a vital role.

For professionals and users engaged in the steel pipe industry, it is essential to understand the basic knowledge of carbon steel pipe.

In this article, we will comprehensively analyze the relevant knowledge of carbon steel pipe for you from the aspects of materials, performance, standards and practical applications. Through the article, let everyone have a deeper understanding of carbon steel pipe.

What is carbon steel pipe

Carbon steel pipe is a pipe made of iron-carbon alloy as the main material, with a carbon content of 0.05%~2.1%.

Among them, carbon is the most important element affecting the performance of carbon steel pipe, which determines the hardness, strength and corrosion resistance of carbon steel pipe.

Material classification of carbon steel pipe

Carbon steel pipe is an alloy pipe with iron and carbon as the main components. Its performance is directly determined by the carbon content.

According to the different carbon content, carbon steel pipe is mainly divided into the following three types:

Low carbon steel

The carbon content is less than 0.25%, the tensile strength is 375-500MPa, it has good plasticity and is easy to weld, and is often used in building supports and water pipes.

Medium carbon steel

The carbon content is between 0.25% and 0.60%. It has high hardness but requires preheating for welding. It is mostly used for mechanical shaft parts.

High carbon steel

The carbon content is greater than 0.60%, it has strong wear resistance but high brittleness, and is suitable for tool manufacturing.

Application of carbon steel pipe

Since carbon steel pipe has good strength and good machinability, it is widely used in the following fields:

- Construction industry: used for building structures, supports, brackets and other parts.

- Water pipes and natural gas pipelines: used for general water and natural gas pipeline systems.

- Industrial pipelines: suitable for transporting non-corrosive liquids and gases, such as oil, coal gas, etc.

Dimensions and weight of carbon steel pipe

| Pipe Size (Nominal) | Schedule | Outside Diameter | Inside Diameter | Wall Thickness | Wt. Lbs. Per Foot |

| 1/2 | 5 | .840 | .710 | .065 | .5383 |

| 1/2 | 10 | .840 | .674 | .083 | .6710 |

| 1/2 | 40 | .840 | .622 | .109 | .8510 |

| 1/2 | STD | .840 | .622 | .109 | .8510 |

| 1/2 | XH | .840 | .546 | .147 | 1.088 |

| 1/2 | 80 | .840 | .546 | .147 | 1.088 |

| 1/2 | 160 | .840 | .466 | .187 | 1.304 |

| 1/2 | XXH | .840 | .252 | .294 | 1.714 |

| 3/4 | 5 | 1.050 | .920 | .065 | .6838 |

| 3/4 | 10 | 1.050 | .884 | .083 | .8572 |

| 3/4 | 40 | 1.050 | .824 | .113 | 1.131 |

| 3/4 | STD | 1.050 | .824 | .113 | 1.131 |

| 3/4 | XH | 1.050 | .742 | .154 | 1.474 |

| 3/4 | 80 | 1.050 | .742 | .154 | 1.474 |

| 3/4 | 160 | 1.050 | .614 | .218 | 1.937 |

| 3/4 | XXH | 1.050 | .434 | .308 | 2.441 |

| 1 | 5 | 1.315 | 1.185 | .065 | .8678 |

| 1 | 10 | 1.315 | 1.097 | .109 | 1.404 |

| 1 | 40 | 1.315 | 1.049 | .133 | 1.679 |

| 1 | STD | 1.315 | 1.049 | .133 | 1.679 |

| 1 | XH | 1.315 | .957 | .179 | 2.172 |

| 1 | 80 | 1.315 | .957 | .179 | 2.172 |

| 1 | 160 | 1.315 | .815 | .250 | 2.844 |

| 1 | XXH | 1.315 | .599 | .358 | 3.659 |

| 1-1/4 | 5 | 1.660 | 1.530 | .065 | 1.107 |

| 1-1/4 | 10 | 1.660 | 1.442 | .109 | 1.806 |

| 1-1/4 | 40 | 1.660 | 1.380 | .140 | 2.273 |

| 1-1/4 | STD | 1.660 | 1.380 | .140 | 2.273 |

| 1-1/4 | XH | 1.660 | 1.278 | .191 | 2.997 |

| 1-1/4 | 80 | 1.660 | 1.278 | .191 | 2.997 |

| 1-1/4 | 160 | 1.660 | 1.160 | .250 | 3.765 |

| 1-1/4 | XXH | 1.660 | .896 | .382 | 5.214 |

| 1-1/2 | 5 | 1.900 | 1.770 | .065 | 1.274 |

| 1-1/2 | 10 | 1.900 | 1.682 | .109 | 2.085 |

| 1-1/2 | 40 | 1.900 | 1.610 | .145 | 2.718 |

| 1-1/2 | STD | 1.900 | 1.610 | .145 | 2.718 |

| 1-1/2 | XH | 1.900 | 1.500 | .200 | 3.631 |

| 1-1/2 | 80 | 1.900 | 1.500 | .200 | 3.631 |

| 1-1/2 | 160 | 1.900 | 1.338 | .281 | 4.859 |

| 1-1/2 | XXH | 1.900 | 1.100 | .400 | 6.408 |

| 2 | 5 | 2.375 | 2.245 | .065 | 1.604 |

| 2 | 10 | 2.375 | 2.157 | .109 | 2.638 |

| 2 | STD | 2.375 | 2.067 | .154 | 3.653 |

| 2 | 40 | 2.375 | 2.067 | .154 | 3.653 |

| 2 | XH | 2.375 | 1.939 | .218 | 5.022 |

| 2 | 80 | 2.375 | 1.939 | .218 | 5.022 |

| 2 | 160 | 2.375 | 1.687 | .344 | 7.462 |

| 2 | XXH | 2.375 | 1.503 | .436 | 9.029 |

| 2-1/2 | 5 | 2.875 | 2.709 | .083 | 2.475 |

| 2-1/2 | 10 | 2.875 | 2.635 | .120 | 3.531 |

| 2-1/2 | STD | 2.875 | 2.469 | .203 | 5.793 |

| 2-1/2 | 40 | 2.875 | 2.469 | .203 | 5.793 |

| 2-1/2 | XH | 2.875 | 2.323 | .276 | 7.661 |

| 2-1/2 | 80 | 2.875 | 2.323 | .276 | 7.661 |

| 2-1/2 | 160 | 2.875 | 2.125 | .375 | 10.01 |

| 2-1/2 | XXH | 2.875 | 1.771 | .552 | 13.70 |

| 3 | 5 | 3.500 | 3.334 | .083 | 3.029 |

| 3 | 10 | 3.500 | 3.260 | .120 | 4.332 |

| 3 | STD | 3.500 | 3.068 | .216 | 7.576 |

| 3 | 40 | 3.500 | 3.068 | .216 | 7.576 |

| 3 | XH | 3.500 | 2.900 | .300 | 10.25 |

| 3 | 80 | 3.500 | 2.900 | .300 | 10.25 |

| 3 | 160 | 3.500 | 2.625 | .438 | 14.32 |

| 3 | XXH | 3.500 | 2.300 | .600 | 18.58 |

| 3-1/2 | 5 | 4.000 | 3.834 | .083 | 3.472 |

| 3-1/2 | 10 | 4.000 | 3.760 | .120 | 4.973 |

| 3-1/2 | STD | 4.000 | 3.548 | .226 | 9.109 |

| 3-1/2 | 40 | 4.000 | 3.548 | .226 | 9.109 |

| 3-1/2 | XH | 4.000 | 3.364 | .318 | 12.51 |

| 3-1/2 | 80 | 4.000 | 3.364 | .318 | 12.51 |

| 3-1/2 | XXH | 4.000 | 2.728 | .636 | 22.85 |

| 4 | 5 | 4.500 | 4.334 | .083 | 3.915 |

| 4 | 10 | 4.500 | 4.260 | .120 | 5.613 |

| 4 | STD | 4.500 | 4.026 | .237 | 10.79 |

| 4 | 40 | 4.500 | 4.026 | .237 | 10.79 |

| 4 | XH | 4.500 | 3.826 | .337 | 14.98 |

| 4 | 80 | 4.500 | 3.826 | .337 | 14.98 |

| 4 | 120 | 4.500 | 3.625 | .438 | 19.00 |

| 4 | 160 | 4.500 | 3.438 | .531 | 22.51 |

| 4 | XXH | 4.500 | 3.152 | .674 | 27.54 |

| 4-1/2 | STD | 5.000 | 4.506 | .247 | 12.54 |

| 4-1/2 | XH | 5.000 | 4.290 | .355 | 17.61 |

| 5 | 5 | 5.563 | 5.345 | .109 | 6.349 |

| 5 | 10 | 5.563 | 5.295 | .134 | 7.770 |

| 5 | STD | 5.563 | 5.047 | .258 | 14.62 |

| 5 | 40 | 5.563 | 5.047 | .258 | 14.62 |

| 5 | XH | 5.563 | 4.813 | .375 | 20.78 |

| 5 | 80 | 5.563 | 4.813 | .375 | 20.78 |

| 5 | 120 | 5.563 | 4.563 | .500 | 27.04 |

| 5 | 160 | 5.563 | 4.313 | .625 | 32.96 |

| 5 | XXH | 5.563 | 4.063 | .750 | 38.55 |

| 6 | 5 | 6.625 | 6.407 | .109 | 7.585 |

| 6 | 10 | 6.625 | 6.357 | .134 | 9.289 |

| 6 | STD | 6.625 | 6.065 | .280 | 18.97 |

| 6 | 40 | 6.625 | 6.065 | .280 | 18.97 |

| 6 | XH | 6.625 | 5.761 | .432 | 28.57 |

| 6 | 80 | 6.625 | 5.761 | .432 | 28.57 |

| 6 | 120 | 6.625 | 5.500 | .562 | 36.39 |

| 6 | 160 | 6.625 | 5.187 | .719 | 45.35 |

| 6 | XXH | 6.625 | 4.897 | .864 | 53.16 |

| 7 | STD | 7.625 | 7.023 | .301 | 23.54 |

| 7 | XH | 7.625 | 6.625 | .500 | 38.04 |

| 7 | XXH | 7.625 | 5.875 | .875 | 63.08 |

| 8 | 5 | 8.625 | 8.407 | .109 | 9.914 |

| 8 | 10 | 8.625 | 8.329 | .148 | 13.40 |

| 8 | 20 | 8.625 | 8.125 | .250 | 22.36 |

| 8 | 30 | 8.625 | 8.071 | .277 | 24.70 |

| 8 | STD | 8.625 | 7.981 | .322 | 28.55 |

| 8 | 40 | 8.625 | 7.981 | .322 | 28.55 |

| 8 | 60 | 8.625 | 7.813 | .406 | 35.64 |

| 8 | XH | 8.625 | 7.625 | .500 | 43.39 |

| 8 | 80 | 8.625 | 7.625 | .500 | 43.39 |

| 8 | 100 | 8.625 | 7.437 | .594 | 50.95 |

| 8 | 120 | 8.625 | 7.187 | .719 | 60.71 |

| 8 | 140 | 8.625 | 7.000 | .812 | 67.76 |

| 8 | 160 | 8.625 | 6.813 | .906 | 74.69 |

| 8 | XXH | 8.625 | 6.875 | .875 | 72.42 |

| 9 | STD | 9.625 | 8.941 | .342 | 33.91 |

| 9 | XH | 9.625 | 8.625 | .500 | 48.73 |

| 10 | 5 | 10.750 | 10.482 | .134 | 15.19 |

| 10 | 10 | 10.750 | 10.420 | .165 | 18.70 |

| 10 | 20 | 10.750 | 10.250 | .250 | 28.04 |

| 10 | 30 | 10.750 | 10.136 | .307 | 34.24 |

| 10 | STD | 10.750 | 10.020 | .365 | 40.48 |

| 10 | 40 | 10.750 | 10.020 | .365 | 40.48 |

| 10 | 60 | 10.750 | 9.750 | .500 | 54.74 |

| 10 | XH | 10.750 | 9.750 | .500 | 54.74 |

| 10 | 80 | 10.750 | 9.562 | .594 | 64.43 |

| 10 | 100 | 10.750 | 9.312 | .719 | 77.03 |

| 10 | 120 | 10.750 | 9.062 | .844 | 89.29 |

| 10 | 140 | 10.750 | 8.750 | 1.000 | 104.1 |

| 10 | 160 | 10.750 | 8.500 | 1.125 | 115.6 |

| 10 | XXH | 10.750 | 8.750 | 1.000 | 104.1 |

| 11 | STD | 11.750 | 11.000 | .375 | 45.56 |

| 11 | XH | 11.750 | 10.7500 | .500 | 60.08 |

| 12 | 5 | 12.750 | 12.420 | .165 | 22.18 |

| 12 | 10 | 12.750 | 12.390 | .180 | 24.16 |

| 12 | 20 | 12.750 | 12.250 | .250 | 33.38 |

| 12 | 30 | 12.750 | 12.090 | .330 | 43.77 |

| 12 | STD | 12.750 | 12.000 | .375 | 49.56 |

| 12 | 40 | 12.750 | 11.938 | .406 | 53.52 |

| 12 | 60 | 12.750 | 11.625 | .562 | 73.15 |

| 12 | XH | 12.750 | 11.750 | .500 | 65.42 |

| 12 | 80 | 12.750 | 11.375 | .688 | 88.63 |

| 12 | 100 | 12.750 | 11.062 | .844 | 107.3 |

| 12 | 120 | 12.750 | 10.750 | 1.000 | 125.5 |

| 12 | 140 | 12.750 | 10.500 | 1.125 | 139.67 |

| 12 | 160 | 12.750 | 10.125 | 1.312 | 160.3 |

| 12 | XXH | 12.750 | 10.750 | 1.000 | 125.5 |

| 14 | 10 | 14.000 | 13.500 | .250 | 36.71 |

| 14 | 20 | 14.000 | 13.375 | .312 | 45.61 |

| 14 | 30 | 14.000 | 13.250 | .375 | 54.57 |

| 14 | STD | 14.000 | 13.250 | .375 | 54.57 |

| 14 | 40 | 14.000 | 13.125 | .438 | 63.44 |

| 14 | 60 | 14.000 | 12.812 | .594 | 85.05 |

| 14 | XH | 14.000 | 13.000 | .500 | 72.09 |

| 14 | 80 | 14.000 | 12.500 | .750 | 106.1 |

| 14 | 100 | 14.000 | 12.125 | .938 | 130.9 |

| 14 | 120 | 14.000 | 11.812 | 1.094 | 150.8 |

| 14 | 140 | 14.000 | 11.500 | 1.250 | 170.2 |

| 14 | 160 | 14.000 | 11.188 | 1.406 | 189.1 |

| 16 | 10 | 16.000 | 15.500 | .250 | 42.05 |

| 16 | 20 | 16.000 | 15.375 | .312 | 52.27 |

| 16 | 30 | 16.000 | 15.250 | .375 | 62.58 |

| 16 | STD | 16.000 | 15.250 | .375 | 62.48 |

| 16 | 40 | 16.000 | 15.000 | .500 | 82.77 |

| 16 | 60 | 16.000 | 14.688 | .656 | 107.5 |

| 16 | XH | 16.000 | 15.000 | .500 | 82.77 |

| 16 | 80 | 16.000 | 14.312 | .844 | 136.6 |

| 16 | 100 | 16.000 | 13.938 | 1.031 | 164.8 |

| 16 | 120 | 16.000 | 13.562 | 1.219 | 192.4 |

| 16 | 140 | 16.000 | 13.125 | 1.438 | 223.6 |

| 16 | 160 | 16.000 | 12.812 | 1.594 | 245.3 |

| 18 | 10 | 18.000 | 17.500 | .250 | 47.39 |

| 18 | 20 | 18.000 | 17.375 | .312 | 58.94 |

| 18 | 30 | 18.000 | 17.125 | .438 | 82.15 |

| 18 | STD | 18.000 | 17.250 | .375 | 70.59 |

| 18 | 40 | 18.000 | 16.875 | .562 | 104.7 |

| 18 | 60 | 18.000 | 16.500 | .750 | 138.2 |

| 18 | XH | 18.000 | 17.000 | .500 | 93.45 |

| 18 | 80 | 18.000 | 16.125 | .938 | 170.9 |

| 18 | 100 | 18.000 | 15.688 | 1.156 | 208.0 |

| 18 | 120 | 18.000 | 15.25 | 1.375 | 244.1 |

| 18 | 140 | 18.000 | 14.875 | 1.562 | 274.2 |

| 18 | 160 | 18.000 | 14.438 | 1.781 | 308.5 |

| 20 | 10 | 20.000 | 19.500 | .250 | 52.73 |

| 20 | 20 | 20.000 | 19.250 | .375 | 78.60 |

| 20 | 30 | 20.000 | 19.000 | .500 | 104.1 |

| 20 | STD | 20.000 | 19.250 | .375 | 78.60 |

| 20 | 40 | 20.000 | 18.812 | .594 | 123.1 |

| 20 | 60 | 20.000 | 18.375 | .812 | 166.4 |

| 20 | XH | 20.000 | 19.000 | .500 | 104.1 |

| 20 | 80 | 20.000 | 17.938 | 1.031 | 208.9 |

| 20 | 100 | 20.000 | 17.438 | 1.281 | 256.1 |

| 20 | 120 | 20.000 | 17.000 | 1.500 | 296.4 |

| 20 | 140 | 20.000 | 16.500 | 1.750 | 341.1 |

| 20 | 160 | 20.000 | 16.062 | 1.969 | 379.2 |

| 24 | 10 | 24.000 | 23.500 | .250 | 63.41 |

| 24 | 20 | 24.000 | 23.250 | .375 | 94.62 |

| 24 | 30 | 24.000 | 22.875 | .562 | 140.7 |

| 24 | STD | 24.000 | 23.250 | .375 | 94.62 |

| 24 | 40 | 24.000 | 22.625 | .688 | 171.3 |

| 24 | 60 | 24.000 | 22.062 | .969 | 238.4 |

| 24 | XH | 24.000 | 23.000 | .500 | 125.5 |

| 24 | 80 | 24.000 | 21.562 | 1.219 | 296.6 |

| 24 | 100 | 24.000 | 20.938 | 1.531 | 367.4 |

| 24 | 120 | 24.000 | 20.375 | 1.812 | 429.4 |

| 24 | 140 | 24.000 | 19.875 | 2.062 | 483.1 |

| 24 | 160 | 24.000 | 19.312 | 2.344 | 542.1 |

Standard basis of carbon steel pipe

- ASTM Standards

ASTM is the largest standard-setting organization in the United States, and its standards are widely used around the world. ASTM steel pipe standards include material, manufacturing process, size, surface treatment and other aspects. Commonly used standards include ASTM A53/A53M, ASTM A106/A106M, ASTM A333/A333M, etc. - DIN Standards

DIN Standards are German standard-setting organizations, and the standards they set are widely used in Europe and around the world. DIN steel pipe standards also include material, manufacturing process, size, surface treatment and other aspects. Commonly used standards include DIN 1626, DIN 17175, DIN 2391, etc. - JIS Standards

JIS is a Japanese standard-setting organization, and its standards are mainly used in Asia. JIS steel pipe standards also include material, manufacturing process, size, surface treatment and other aspects. Commonly used standards include JIS G3454, JIS G3455, JIS G3456, etc.

Carbon steel pipe VS black pipe

| Parameter | Carbon Steel Pipe | Black Pipe (Black Steel Pipe) |

| Definition | General term for steel pipes with 0.1-2.1% carbon content | Specific type of unfinished carbon steel pipe with dark oxide surface |

| Surface Finish | Multiple options: Galvanized, coated, polished | Uncoated with mill-scale oxide layer (Fe₃O₄) |

| Manufacturing Process | Can be hot-finished or cold-drawn | Exclusively hot-rolled |

| Corrosion Resistance | Varies by treatment (galvanized > coated > bare) | Poor (requires external protection) |

| Primary Standards | ASTM A53, A106, API 5L | ASTM A53/A106 (Grade B common) |

| Typical Applications | Structural, pressure vessels, machinery | Gas distribution, fire sprinklers, non-potable water |

| Wall Thickness | Wide range (schedule 5S to XXS) | Typically schedule 40 or 80 |

| Dimensional Tolerance | Tighter controls (ASTM A530) | Standard mill tolerances |

| Cost Factor | Higher (varies by treatment) | Lower (minimal post-processing) |

| Weldability | Excellent (pre-cleaning required for coated) | Good (mill scale must be removed first) |

| Temperature Range | -29°C to 425°C (A106 Grade B) | -29°C to 425°C (similar to base carbon steel) |

| Surface Treatment | Optional: painting, FBE coating, galvanizing | None (used as-is or painted post-installation) |

Carbon steel pipe VS MS pipe

| Parameter | Carbon Steel Pipe | Mild Steel (MS) Pipe |

| Carbon Content | 0.1% – 2.1% (typically 0.3%-1.5%) | 0.05% – 0.25% (max 0.29%) |

| Yield Strength | 240-550 MPa (varies by grade) | 170-250 MPa (typical) |

| Tensile Strength | 415-1035 MPa | 300-500 MPa |

| Hardness (Brinell) | 120-300 HB | 70-150 HB |

| Ductility | Moderate (15-25% elongation) | High (25-40% elongation) |

| Weldability | Requires pre/post-heat treatment (C>0.3%) | Excellent (low carbon equivalent) |

| Corrosion Resistance | Similar (both require protection) | Slightly better due to lower carbon content |

| ASTM Standards | A53, A106, A333, API 5L | A283, A36, A573 |

| Typical Applications | High-pressure systems, structural supports | Low-stress applications, furniture frames |

| Heat Treatment | Often normalized or quenched & tempered | Rarely heat treated |

| Cost Factor | Higher (15-30% more than MS) | Lower |

| Machinability | Moderate (tool wear increases with C%) | Excellent |

| Impact Resistance | Lower at sub-zero temperatures | Better low-temperature performance |

| Surface Finish | Multiple options available | Typically mill finish |

Top ten carbon steel pipe manufacturers in Asia

| Rank | Company Name | Location | Main Products |

| 1 | TPCO (Tianjin Pipe Corporation) | Tianjin, China | – Seamless carbon steel pipes (API 5L, ASTM A106) – OCTG pipes for oil & gas |

| 2 | JFE Steel Corporation | Tokyo, Japan | – High-grade carbon steel pipes – ERW/LSAW pipes for energy & construction |

| 3 | Nippon Steel Corporation | Tokyo, Japan | – Seamless/ERW pipes (ASTM A53, A106) – Line pipes for high-pressure applications |

| 4 | Hyundai Steel | Seoul, South Korea | – ERW carbon steel pipes – Structural pipes (ASTM A500) |

| 5 | Valin Steel Group | Hunan, China | – Seamless/welded carbon steel pipes – API 5L PSL1/PSL2 pipelines |

| 6 | Beijing Metleader Pipeline Technology Inc. | Beijing, China | – Precision carbon steel pipes – FBE/3LPE anti-corrosion coated pipes |

| 7 | Jindal SAW Ltd. | Rajasthan, India | – LSAW/ERW pipes (API 5L X70-X80) – Large-diameter pipes for water transmission |

| 8 | Husteel Group | Zhejiang, China | – Seamless pipes (ASTM A106, A53) – High-pressure boiler tubes |

| 9 | Korea Steel Pipe Co., Ltd. | Busan, South Korea | – ERW carbon steel pipes – Automotive & mechanical structural pipes |

| 10 | United Steel Industries (Malaysia) | Kuala Lumpur, Malaysia | – API 5L carbon steel pipes – Sour service pipes (NACE MR0175 compliant) |

How to choose carbon steel pipe

- Corrosive environment: Ordinary carbon steel pipes are not acid-resistant and need to be galvanized if in contact with seawater.

- Pressure requirements: Seamless pipes are preferred in high-pressure scenarios. For example, 16Mn has a 30% increase in strength over Q235.

- Cost control: The price of welded pipes is 40%-60% lower than that of seamless pipes.

Summary

As an important industrial material, carbon steel pipes have been widely used in various fields, from energy, construction to chemical, aerospace and other industries.

By understanding the basic knowledge of carbon steel pipes, including its material, performance, production process, application field, etc., you can better select and use steel pipes and provide reliable support for various engineering projects.

If you have any needs or questions about carbon steel pipes, please feel free to contact us! We provide you with a one-stop steel pipe solution to ensure that you can find the most suitable products to meet your project needs.

To learn more about our products, please subscribe to our youtube and LinkedIn channels.